COL 10(Suppl.), S10601(2012) CHINESE OPTICS LETTERS June 30, 2012

Theoretical analysis of temperature sensor

based on dual-core fiber

Daru Chen (

XXX

)

1,2∗

, Gufeng Hu (

¹¹¹

)

1

, Baojin Peng (

$$$

???

)

1

,

Genzhu Wu (

ÇÇÇ

ÎÎÎ

)

1

, and H. Y. Tam (

uuu

)

2

1

Institute of Information Optics, Zhejiang Normal University, Jinhua 321004, China

2

Photonics Research Centre, Department of Electrical Engineering,

The Hong Kong Polytechnic University, Hong Kong SAR, China

∗

Corresponding author: daru@zjnu.cn

Received August 10, 2011; accepted October 25, 2011; posted online April 18, 2012

A novel temperature sensor based on a dual-core fiber (DCF) is proposed and theoretically analyzed. The

DCF-based temperature sensor is simply formed by splicing a segment of DCF to two segments of single

mode fibers, where the DCF is used as the sensing element. The mode coupling between two fiber cores of

the DCF is sensitive to the temperature-induced index change of the silica in the DCF. Simulations show

that there is a linear relationship between the temperature of the DCF and the wavelength shift of th e

output spectrum of the DCF-based t emperature sensor when the broadband light is injected into one fiber

core of the DCF. Temperature sensors based on DCFs with different parameters for temperature sensing

are also investigated.

OCIS codes: 060.2310, 060.2280, 060.2370.

doi: 10.3788/COL201210.S10601.

Optical fiber senso rs have attrac ted considerable atten-

tion in the past three decades due to their advantages

such as small size, light weight, high sensitivity, mul-

tiplexing capability, immunity to electromagnetic in-

terference, and so o n

[1−5]

. Among them, temperature

sensors based on optical fibe r devices using various tech-

niques such as Raman and Brilllouin scattering

[6−9]

,

fiber Bragg grating (FBG)

[10−12]

, long-period fibe r g rat-

ing (LPG)

[13,14]

, and interferometry

[15−18]

have been

extensively investigated due to their broad applications

in fundamental research, electrical power engineering,

astronautical engineering, energy and power engineering,

and chemical industry. Temperature sensors based on the

Raman/Brilllouin scattering have successfully achieved

distributed temp e rature measurement but suffer from

the limited measurement range (less than 100

◦

C). FBG

and LPG are two of the most particular temperature

fiber sensors because of its capability of multiplexing.

However, we need costly fabrication system fo r the

FBG (LPG) and the operational temperature of the

FBG (LPG) fa bricated using UV las e r writing is usually

very low (e.g., 300

◦

C for the FBG wr itten into the B-

and Ge-codoped silicate fiber) due to the poor thermal

stability of the UV-induced refractive index change

[19]

.

Special matericals or fabrication pro cessing are needed

for high-temperature FBG sensors

[20−23]

. Temperature

sensors based on Fabry–Perot interferometer

[24−26]

and

modal interferometer

[27,28]

have successfully achieved

high-tempe rature se nsing, among which special fibers

such as the photonic crystal fibe r and multimode fiber

(MMF) have been used for high-temperature sensing.

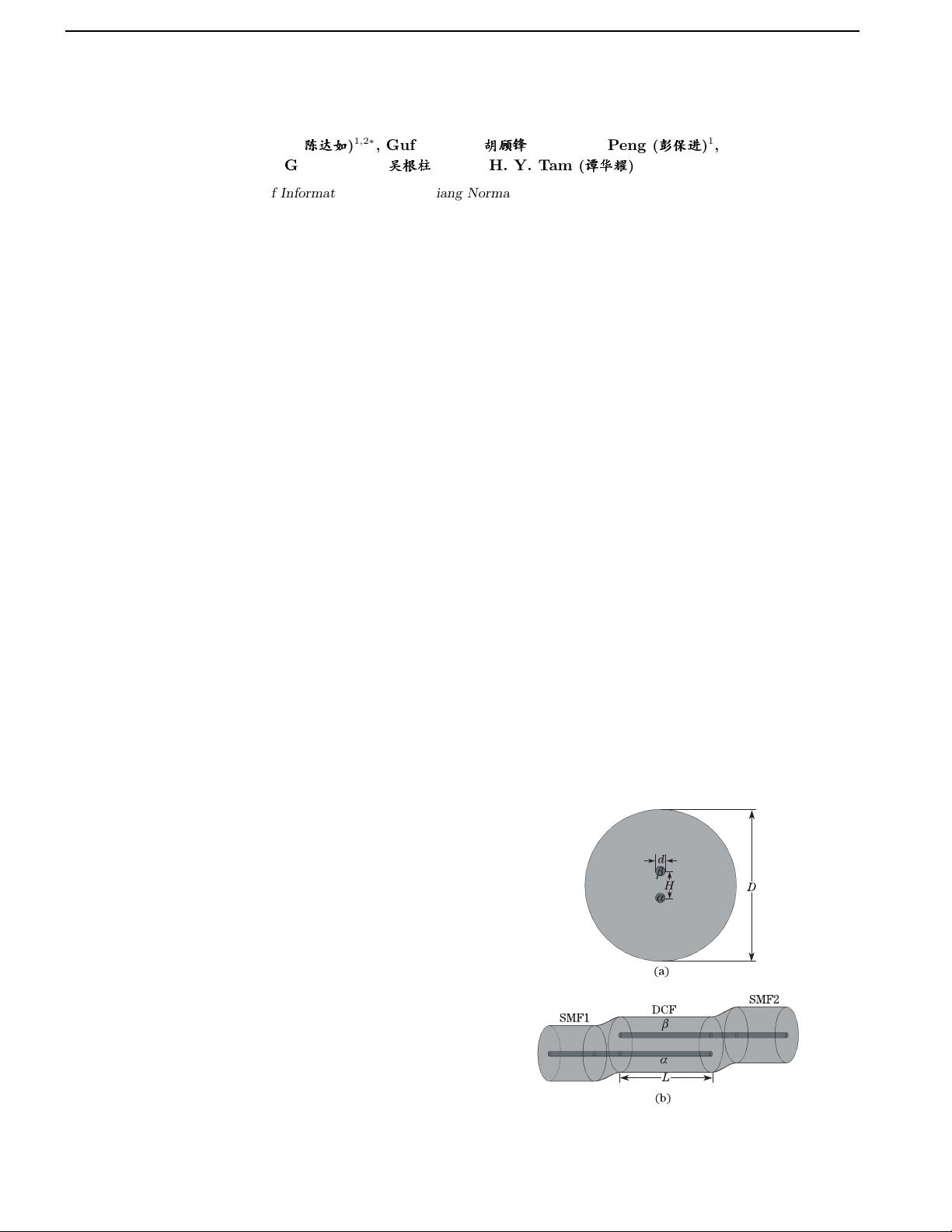

In this letter, we propose a kind of novel temperature

sensor based o n a dual-core fiber (DCF) with an opera-

tional principle of the mode coupling between two fiber

cores (formed two individual waveguides). The DCF-

based temperature sensor is simply formed by splicing a

segment of DCF to two segments of single mode fibers

(SMFs). Temperature information is achieved by mea-

suring the wavelength shift of the output spectrum of

the DCF-based temperature sensor. The proposed DCF-

based temperature sensor can be used for high tempe r-

ature (> 1 000

◦

C) sensing with a sensitivity of about 7

pm/

◦

C.

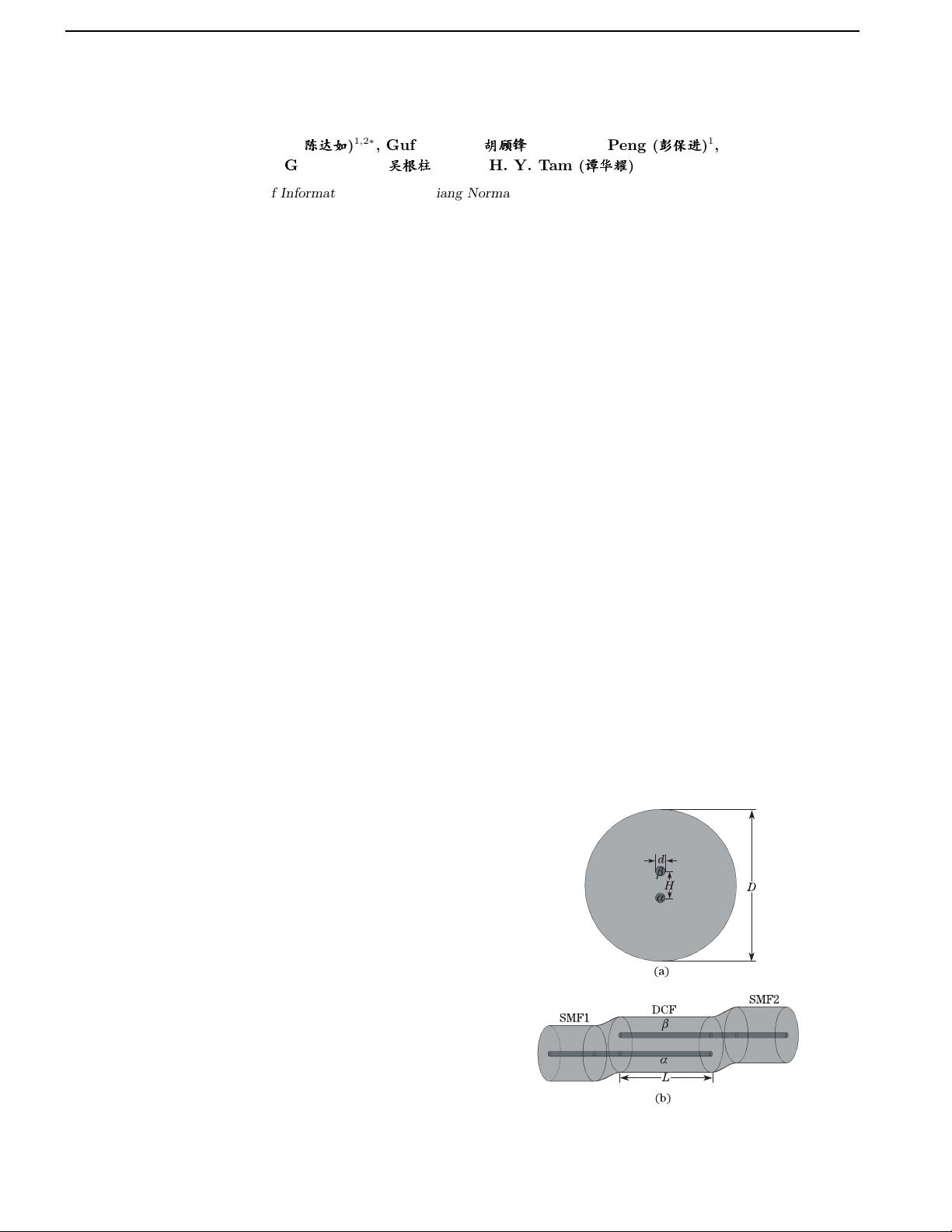

Figure 1(a) shows the cross-section of the proposed

DCF. Two fiber cores (α and β) with the diameter (d)

and the center-to-center distance (H) are arranged sy m-

metrically in the cross-se c tion of the DCF. The outside

diameter of the DCF is D, which is fixed to be 125 µm

to match the SMF. To simplify analysis, the refrac-

tive index of the silica under the reference tempe rature

T = 0

◦

C is assumed to be 1.45 and the refractive in-

dex difference between the fiber core and fiber cladding

is δ, which is 0.32%, 0.36%, and 0.40% for different

DCFs in our calculations, respectively. Figure 1(b)

Fig. 1. (a) Cross-section of the proposed DCF and (b) struc-

ture of the D CF-based temperature sensor.

1671-7694/2012/S10601(4) S10601-1

c

2012 Chinese Optics Letters