灵活印刷技术Flexography:原理与应用

版权申诉

124 浏览量

更新于2024-04-04

收藏 1.88MB PPTX 举报

Flexography, also known as flexographic printing, is a modern printing process that utilizes a flexible relief plate adhered to a printing cylinder. It is an evolution of the traditional letterpress printing method, offering greater versatility and the ability to print on a wide range of substrates including plastic, metallic films, cellophane, and paper.

One of the key advantages of flexography is its versatility in printing on non-porous substrates, making it ideal for various types of food packaging where a high level of ink adhesion and fast drying times are crucial. This makes flexography a preferred choice for many packaging applications in the food industry.

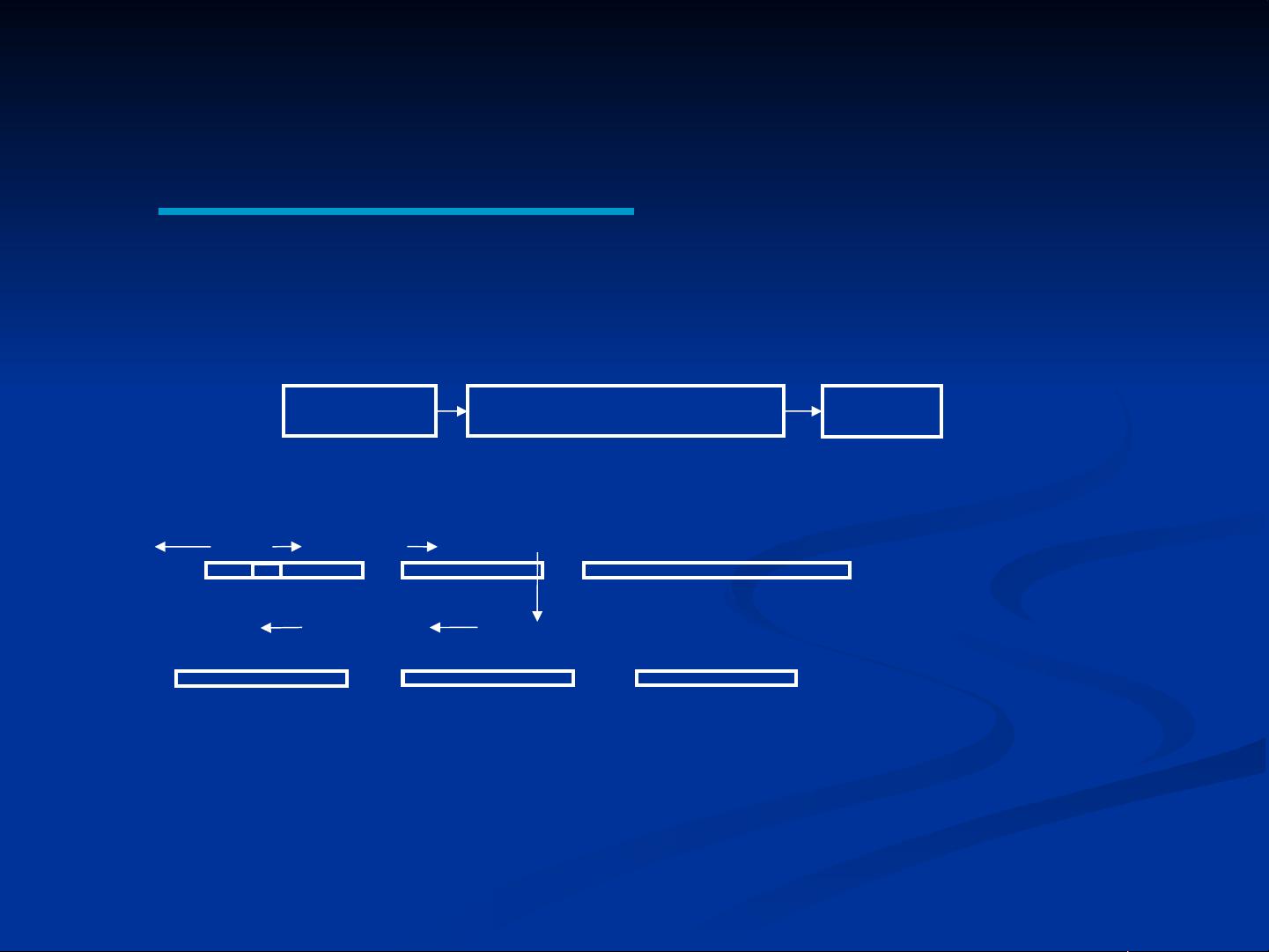

The process of flexographic printing involves the transfer of ink from the flexible relief plate onto the printing surface. This is achieved by rotating the printing cylinder, which is in contact with the substrate, and applying pressure to transfer the ink. The flexibility of the relief plate allows for consistent ink transfer and high-quality printing results.

In addition to its suitability for food packaging, flexography is also widely used in the production of labels, tags, and flexible packaging materials. Its ability to print on a variety of substrates and produce vibrant, high-resolution images makes it a popular choice for many industries.

Overall, flexography offers a cost-effective and efficient printing solution for a wide range of applications, making it a valuable technology in the modern printing industry. Its versatility, adaptability, and high-quality results have solidified its position as a preferred printing method for many businesses worldwide.

点击了解资源详情

点击了解资源详情

点击了解资源详情

2021-10-03 上传

2021-10-02 上传

2021-10-01 上传

2021-10-05 上传

2021-10-04 上传

2021-10-03 上传

woshifafuge

- 粉丝: 8

- 资源: 58万+