FEM Modeling and Simulation of a Layered SAW

device Based on ZnO/128° YX LiNbO

3

Zaid. T. Salim

School of Nano Electronic Engineering

University Malaysia Perlis (UniMAP)

Perlis, Malaysia

zaidtareq86@gmail.com

U. Hashim, and M. K. Md. Arshad

Institution of Nano Electronic Engineering

University Malaysia Perlis (UniMAP)

Perlis, Malaysia

uda@unimap.edu.my

mohd.khairuddin@unimap.edu.my

Abstract—In this paper, the modeling and simulation of a

layered surface acoustic wave device based on ZnO/128° YX

LiNbO

3

were conducted using Finite Element Method (FEM) in

COMSOL Multiphysics 4.3b platform. The SAWs propagation

characteristics were numerically investigated with variation in

the ZnO layer thickness. The results show that the SAW device

frequency response was varied with the ZnO layer thickness

from 166.1 MHz to 150.4 MHz. The free and metalized phase

velocities (

f

and

m

) were calculated and used to calculate the

electromechanical coupling coefficient (K

2

) of the structure. The

results show that a large coupling coefficient of 6.05% can be

obtained in 500 nm ZnO layer thickness which is in a good

agreement with the data published by Nakamura and

Hanamoka.

Keywords—FEM; SAW device; Surface acoustic wave; 128°

YX LiNbO

3

; ZnO

I. INTRODUCTION

Surface acoustic wave devices are used in many types of

electronic components such as filters, resonators and actuators

[1]. Recently, it were investigated both theoretically and

experimentally as gas sensor, pressure sensors, bio sensors and

many other applications such as humidity, magnetic field and

ultrasonic sensors [2-4].A large number of studies were

conducted to develop layered SAW devices by utilizing a

piezoelectric thin film over the substrate to modify the SAW

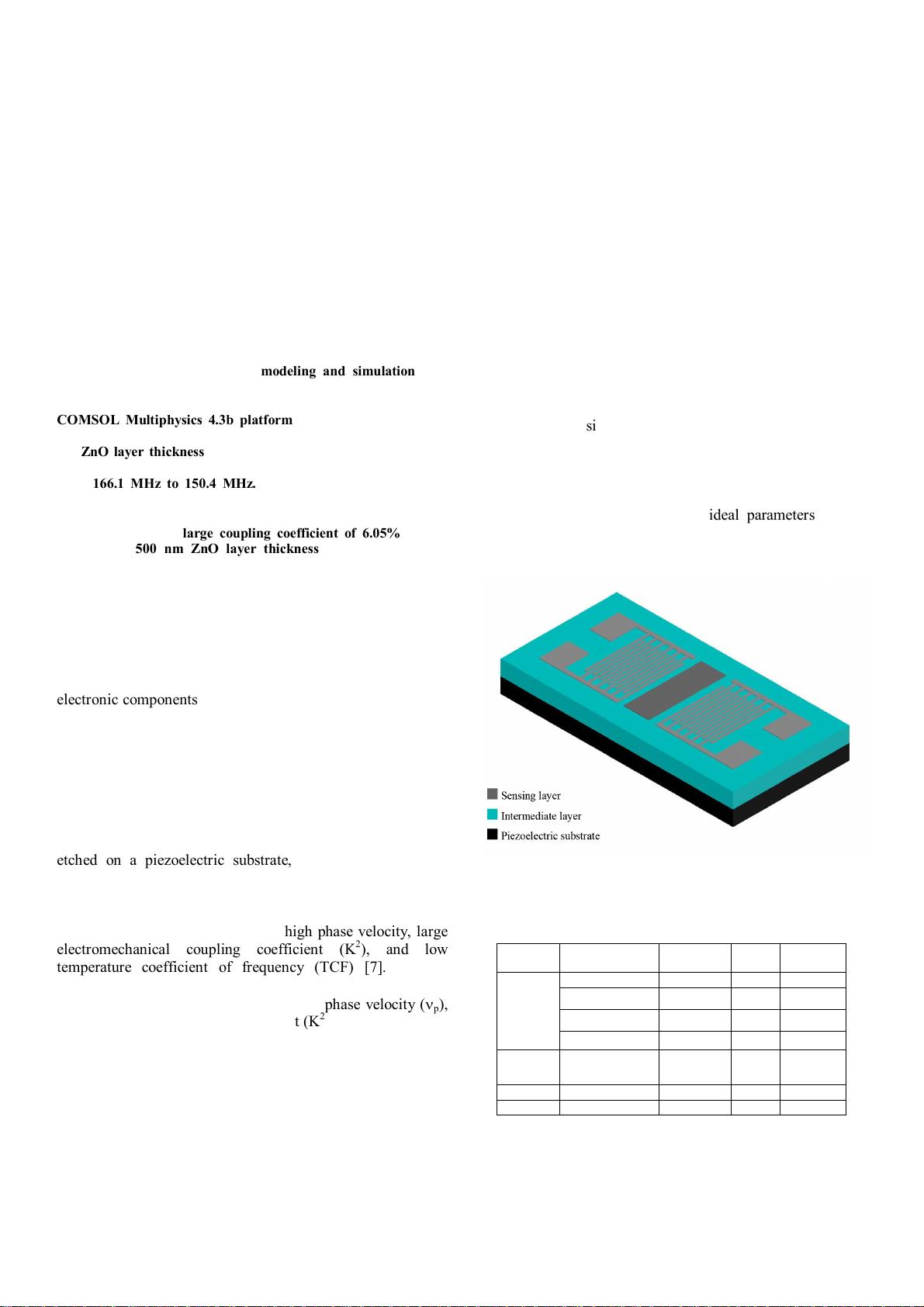

device performance [5]. A typical two-port layered SAW

device is consist of two interdigitated transducers (IDTs)

etched on a piezoelectric substrate, intermediate layer and

sensing layer [6] as illustrated in Fig. 1.

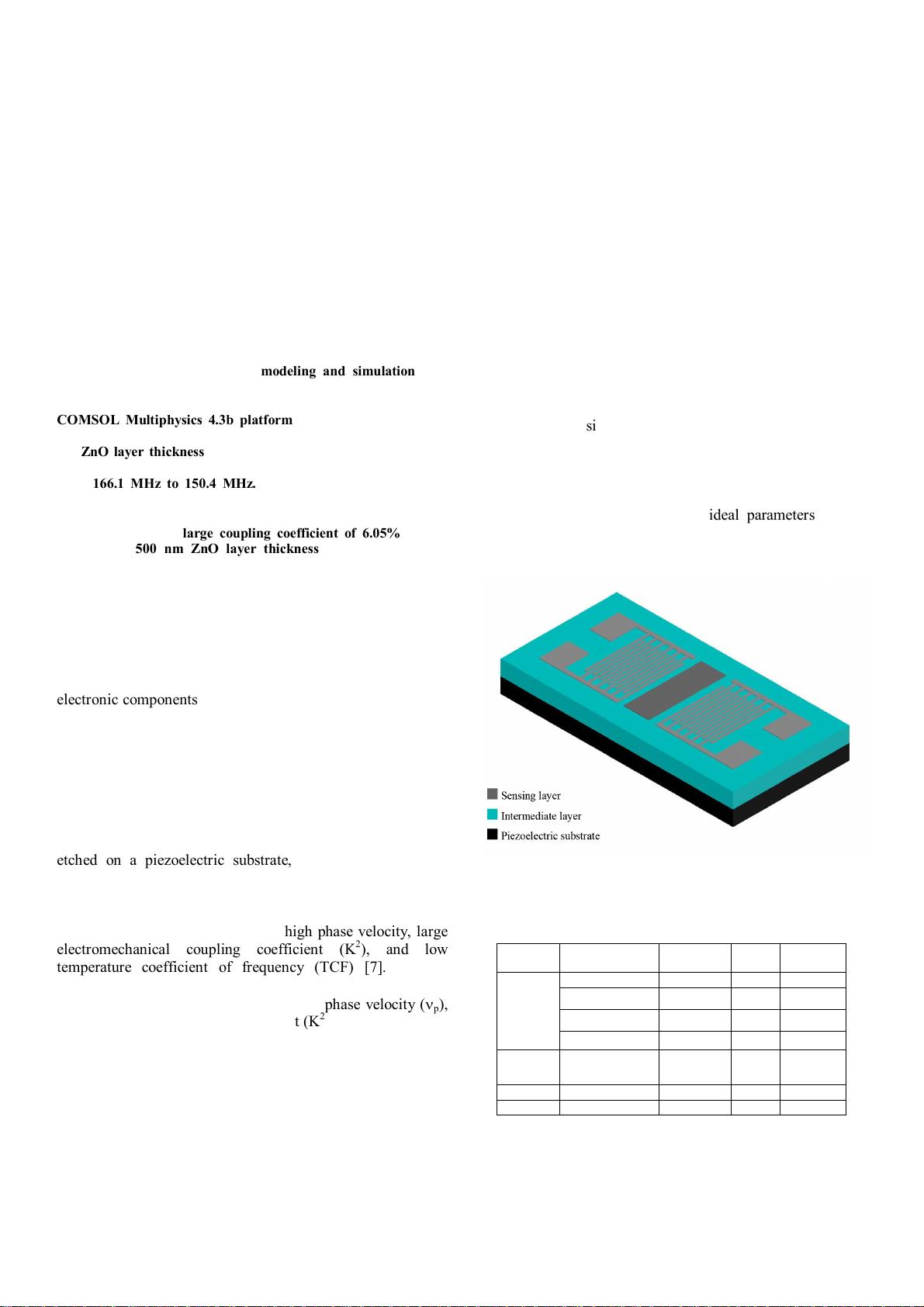

Various factors must be considered in the selection of the

piezoelectric materials used in the SAW device. The

piezoelectric materials must have a high phase velocity, large

electromechanical coupling coefficient (K

2

), and low

temperature coefficient of frequency (TCF) [7]. Table I

summarize the properties of the most common piezoelectric

materials. Choi et al [8] reported that the phase velocity (

p

),

electromechanical coupling coefficient (K

2

) and the sensitivity

can be modified by utilizing a dielectric intermediate layer to

the SAW device structure. Furthermore, Armstrong et al. [9]

reported that when using a piezoelectric thin film over a

piezoelectric substrate, more efficient SAWs can be obtained.

ZnO is a commonly used piezoelectric material due to its

electrical, structural and optical properties. ZnO thin films

were used to generate SAWs over a non-piezoelectric

substrate such as silicon glass and diamond [10-12]. Kalantar-

Zadeh et al. [13] reported that using a ZnO thin film can

increase the SAW device sensitivity compared to SiO

2

in

study using ST-quarts substrate. We can conclude that a pre-

fabrication simulation can help us to investigate the SAW

device performance and select the ideal parameters for the

required application by gaining a better understanding about

the propagation characteristics of the structure.

Fig. 1. Schematic of a typical two-port layered SAW device.

TABLE I. THE MOST COMMON PIEZOELECTRIC MATERIALS USED IN SAW

DEVICES.

Material Orientation/cut

(m/s)

K

2

(%)

TCD

(ppm)/ºC

LiNbO

3

Y-Z 3488 4.5 94

41º Y-X 4751 11.3 50

64º Y-X 4478 17.2 70

128º Y-X 3996 5.5 75

LiTaO

3

77.1º Y-Z

112º X-Y

3254

3300

0.72

0.70

35

18

ZnO

(11-20) 2700 1.1 59-42

SiO

2

47.5º Y-X(ST) 3158 0.11 0

IEEE-ICSE2016 Proc. 2016, Kuala Lumpur, Malaysia

978-1-5090-2383-7/16/$31.00 ©2016 IEEE

好的基

片材料

必须要

包含三

个特

点:1:

高的相

位速

度,2:

大的机

电耦合

系数,

3:低的

频率温

度系数

在一般的基片无法满足一

个滤波器需要的三个要求

时,我们可以使用一个中

间的介电层来改变一个基

片的系数三种基本的系数