404

HVAC&R

RESEARCH

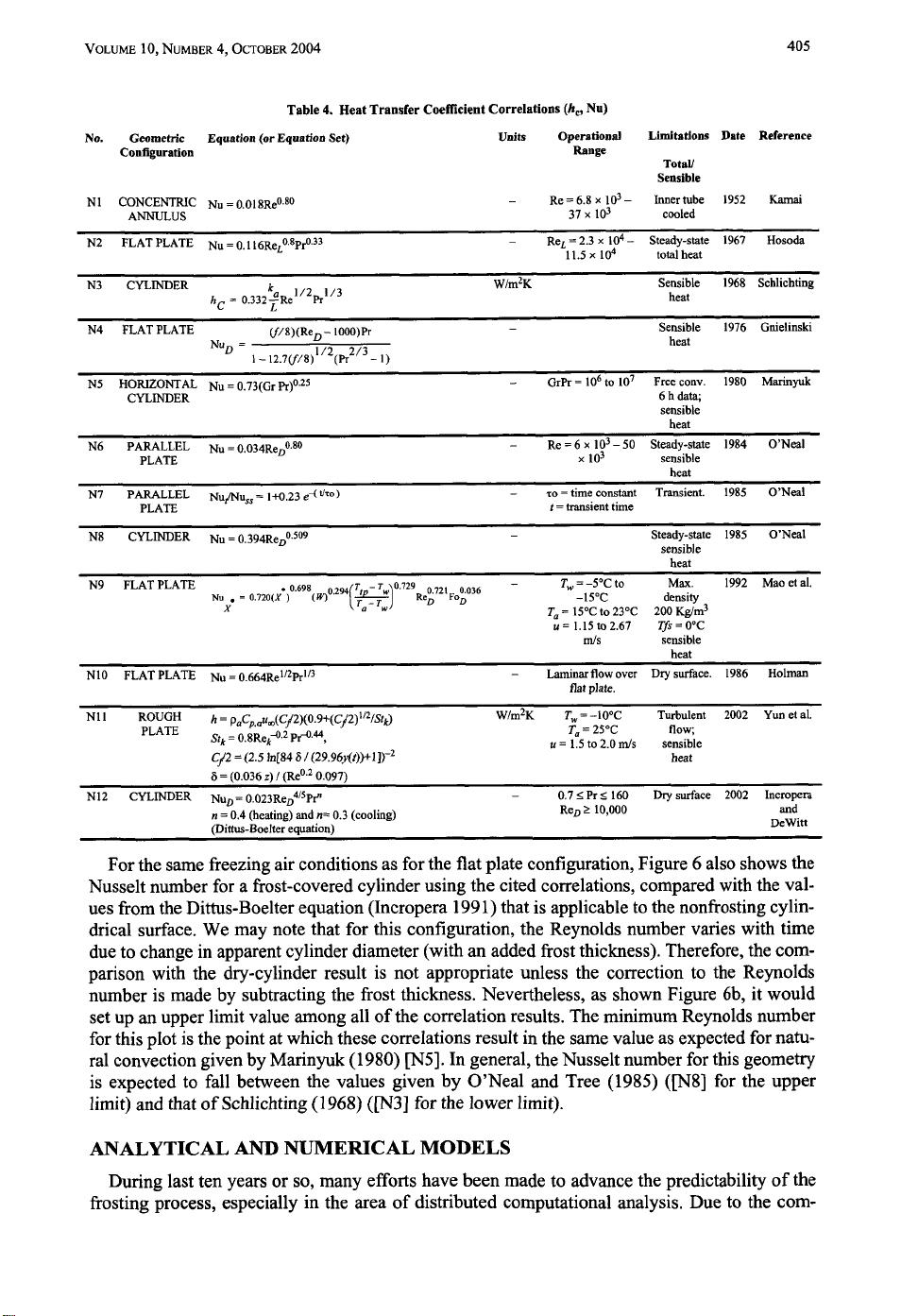

Heat Transfer Coefficient (Nusselt number)

Two types of heat transfer coefficients have been reported in the literature-one considers the

overall effect of frost on the heat transfer rate in the heat exchanger, defined with the underlying

cold surface temperature, while the other gives the heat transfer from the air to the frost layer at

the frost layer surface, defined by the frost surface temperature. Although the first definition cor-

rectly includes the latent load effect of frost on the equipment, the latter

is

more consistent with

the definition of reflecting convective sensible heat removed from ambient. Therefore, we only

report the latter type of correlations here, also because this is the one required in a frost growth

model. Table

4

summarizes the results.

As

can be seen, a significant number of studies have been reported in the literature. Most cor-

relations follow the same form as the classic Reynolds number or Grashof number correlations

for the nonfrosting surfaces. Two correlations by Mao et al. (1992) and O’Neal and Tree (1985)

were developed directly from their experiments where the time-dependent Nusselt number is

correlated. Although they are very useful for validating the model simulation, the use of correla-

tions has to be strictly limited to the reported range

of

operating conditions.

In some of the experimental work reported, the heat transfer coefficient is defined as follows:

where

qw

is the heat flux measured from an imbedded heat flux meter on the cold surface

between the frost layer and cold plate or derived

from

the energy balance. According to the heat

balance, the above-defined heat transfer coefficient includes both the sensible heat between the

ambient and frosting surface and the latent heat due to frost growth. This explains why the

Nus-

selt number with frost

is

higher than that for nonfrosting surfaces, meaning the extra cooling

load for the refrigerating coil. If one needs to consider only the heat transfer between the ambi-

ent and frost surface (not the bare equipment surface), the following should hold:

PPsg

dF

hsensible

hW

T,

-

Tydt

(4)

The second term on the right side of the above equation depends on time in a frosting process.

In many modeling studies, as will be discussed later, it

is

generally assumed that hsensible follows

the correlations for nonfrosting surfaces and is, therefore, independent of time if the ambient

condition remains stable. However, one may argue that under turbulent flow ambient conditions,

frost formation results in the time-dependent surface roughness that will lead to the time-depen-

dent

hsensible.

It is, therefore, necessary to conduct further studies to confirm or find the accuracy

of convective heat transfer coefficient

hsensible

under frosting conditions.

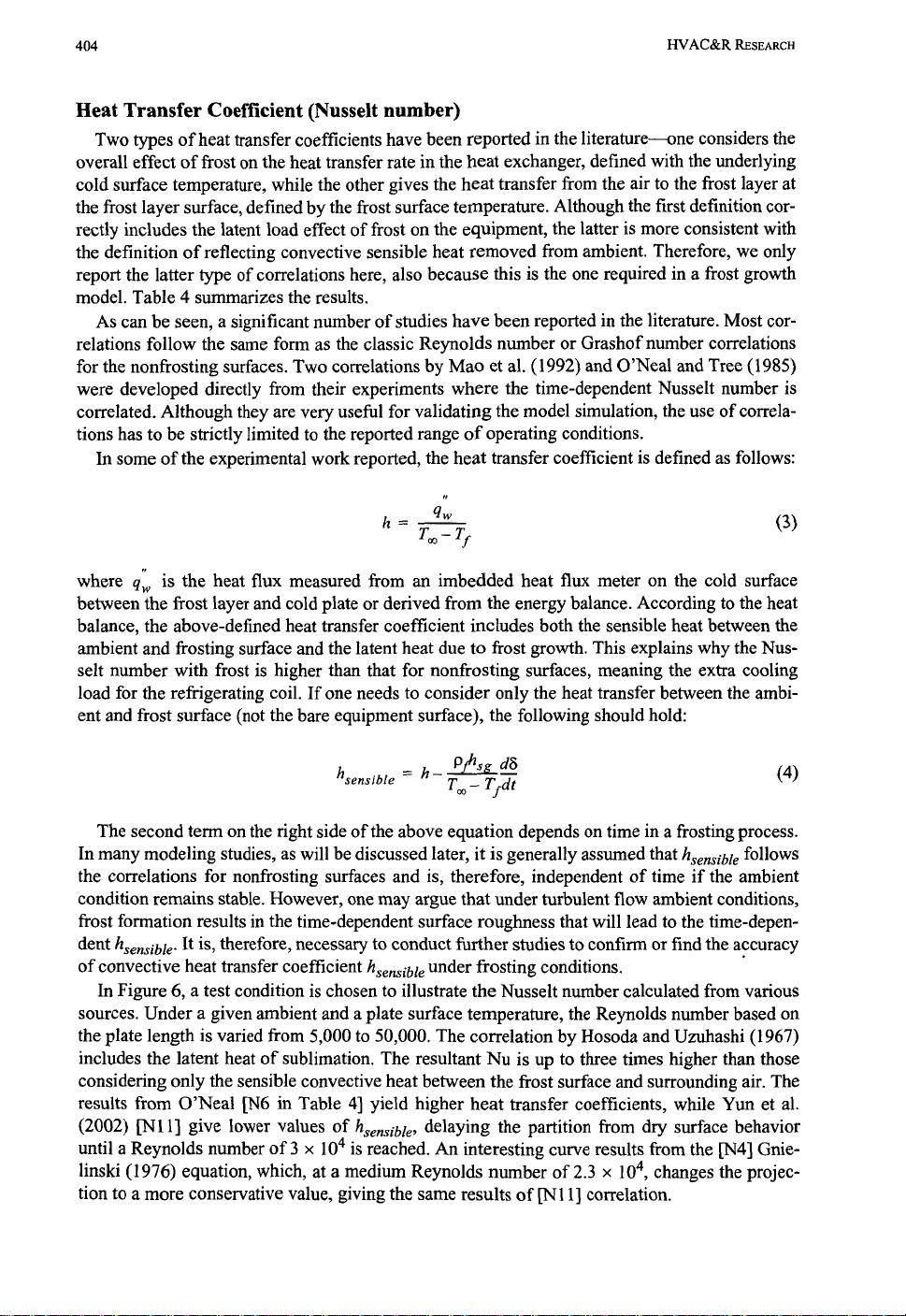

In Figure 6, a test condition is chosen to illustrate the Nusselt number calculated from various

sources. Under a given ambient and a plate surface temperature, the Reynolds number based on

the plate length is varied from

5,000

to

50,000.

The correlation by

Hosoda

and Uzuhashi (1967)

includes the latent heat of sublimation. The resultant

Nu

is up to three times higher than those

considering only the sensible convective heat between the frost surface and surrounding air. The

results from O’Neal

[N6

in Table 41 yield higher heat transfer coefficients, while

Yun

et al.

(2002) IN111 give lower values of

hsensible,

delaying the partition from dry surface behavior

until a Reynolds number of 3

x

1

O4

is reached.

An

interesting curve results from the [N4] Gnie-

linski (1976) equation, which, at a medium Reynolds number of 2.3

x

lo4,

changes the projec-

tion to a more conservative value, giving the same results of

ml

i]

correlation.

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:26:33 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---