优化测量系统分析及评估方法(PPT32)

版权申诉

87 浏览量

更新于2024-04-05

收藏 1.41MB PPTX 举报

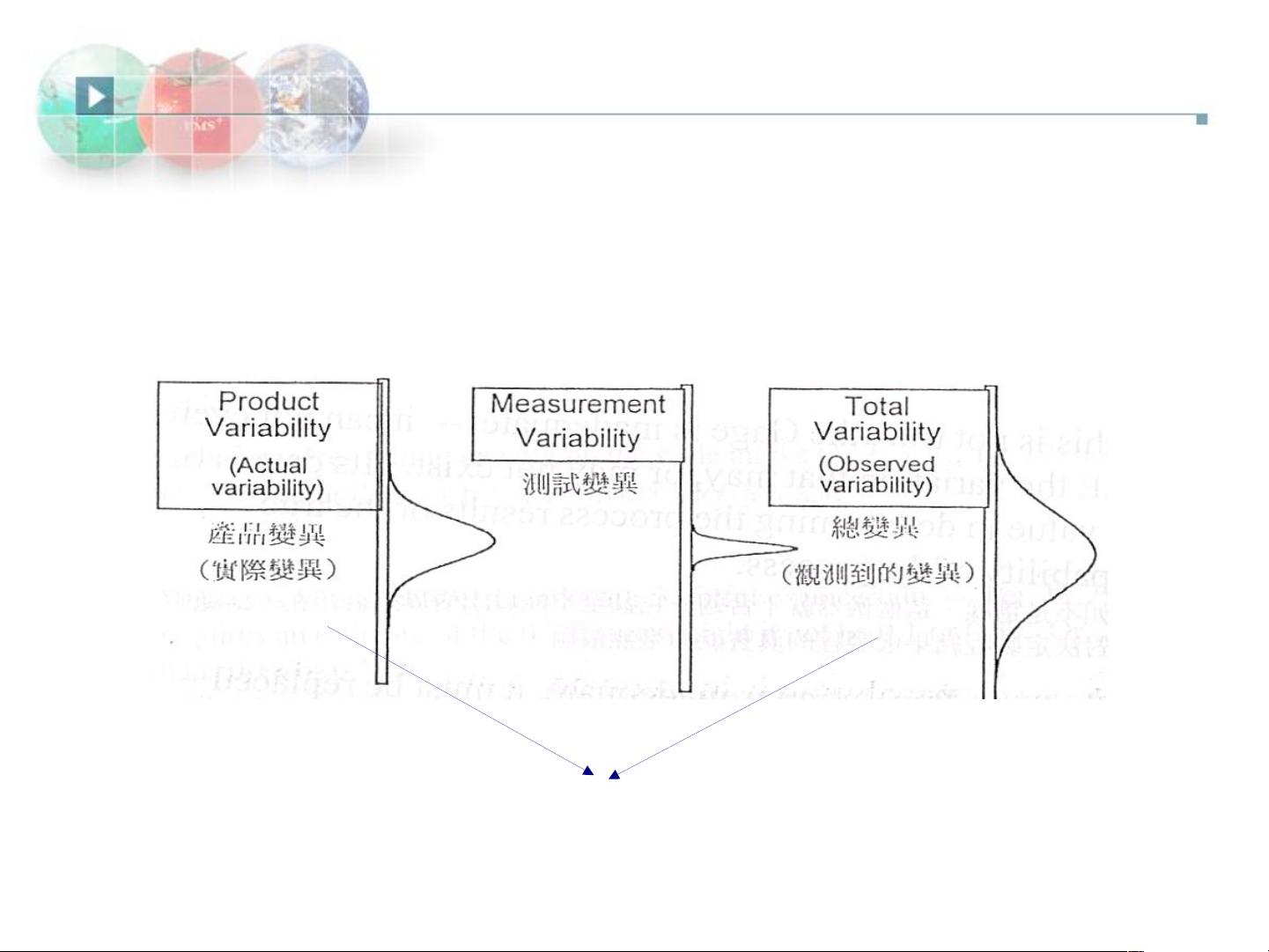

Measurement System Analysis (MSA) is a critical tool used in quality control and process improvement to assess the reliability and accuracy of a measurement system. A measurement system encompasses the procedures, equipment, software, and personnel involved in measuring the quality characteristics of a product. The data generated by the measurement system is crucial for making informed decisions and ensuring the consistency and accuracy of the measurement process.

In order to ensure the reliability of the measurement system, it is essential to conduct a thorough analysis of its performance. This involves evaluating various aspects such as bias, linearity, stability, repeatability, and reproducibility. By identifying and quantifying sources of variation within the measurement system, it becomes possible to determine whether the system is capable of producing accurate and consistent results.

MSA is typically conducted using statistical techniques such as Gauge R&R (Repeatability and Reproducibility) analysis, which helps identify the amount of variation attributable to the measurement system itself versus the variation attributable to the parts being measured. This analysis is crucial for determining the capability of the measurement system and making necessary adjustments or improvements to ensure accurate and reliable measurement results.

In conclusion, Measurement System Analysis is a fundamental component of quality control and process improvement. By assessing the performance of the measurement system and identifying sources of variation, organizations can ensure the accuracy and reliability of their measurement processes, ultimately leading to improved product quality and customer satisfaction.

点击了解资源详情

点击了解资源详情

点击了解资源详情

文档爱好者

- 粉丝: 8

- 资源: 29万+

最新资源

- 深入浅出:自定义 Grunt 任务的实践指南

- 网络物理突变工具的多点路径规划实现与分析

- multifeed: 实现多作者间的超核心共享与同步技术

- C++商品交易系统实习项目详细要求

- macOS系统Python模块whl包安装教程

- 掌握fullstackJS:构建React框架与快速开发应用

- React-Purify: 实现React组件纯净方法的工具介绍

- deck.js:构建现代HTML演示的JavaScript库

- nunn:现代C++17实现的机器学习库开源项目

- Python安装包 Acquisition-4.12-cp35-cp35m-win_amd64.whl.zip 使用说明

- Amaranthus-tuberculatus基因组分析脚本集

- Ubuntu 12.04下Realtek RTL8821AE驱动的向后移植指南

- 掌握Jest环境下的最新jsdom功能

- CAGI Toolkit:开源Asterisk PBX的AGI应用开发

- MyDropDemo: 体验QGraphicsView的拖放功能

- 远程FPGA平台上的Quartus II17.1 LCD色块闪烁现象解析