"注塑模具设计与加工工艺综述:塑料工业发展趋势与设计原则详解"

需积分: 0 5 浏览量

更新于2024-03-21

收藏 802KB DOC 举报

Injection molding is a crucial process in the plastic industry, and as the economy continues to grow, the plastic industry is expected to thrive. This process involves heating and melting loose granular or powdered materials to create a molten plastic that is then injected into a mold at high pressure. After cooling and solidifying, the mold is opened to reveal a plastic component with the desired shape and size.

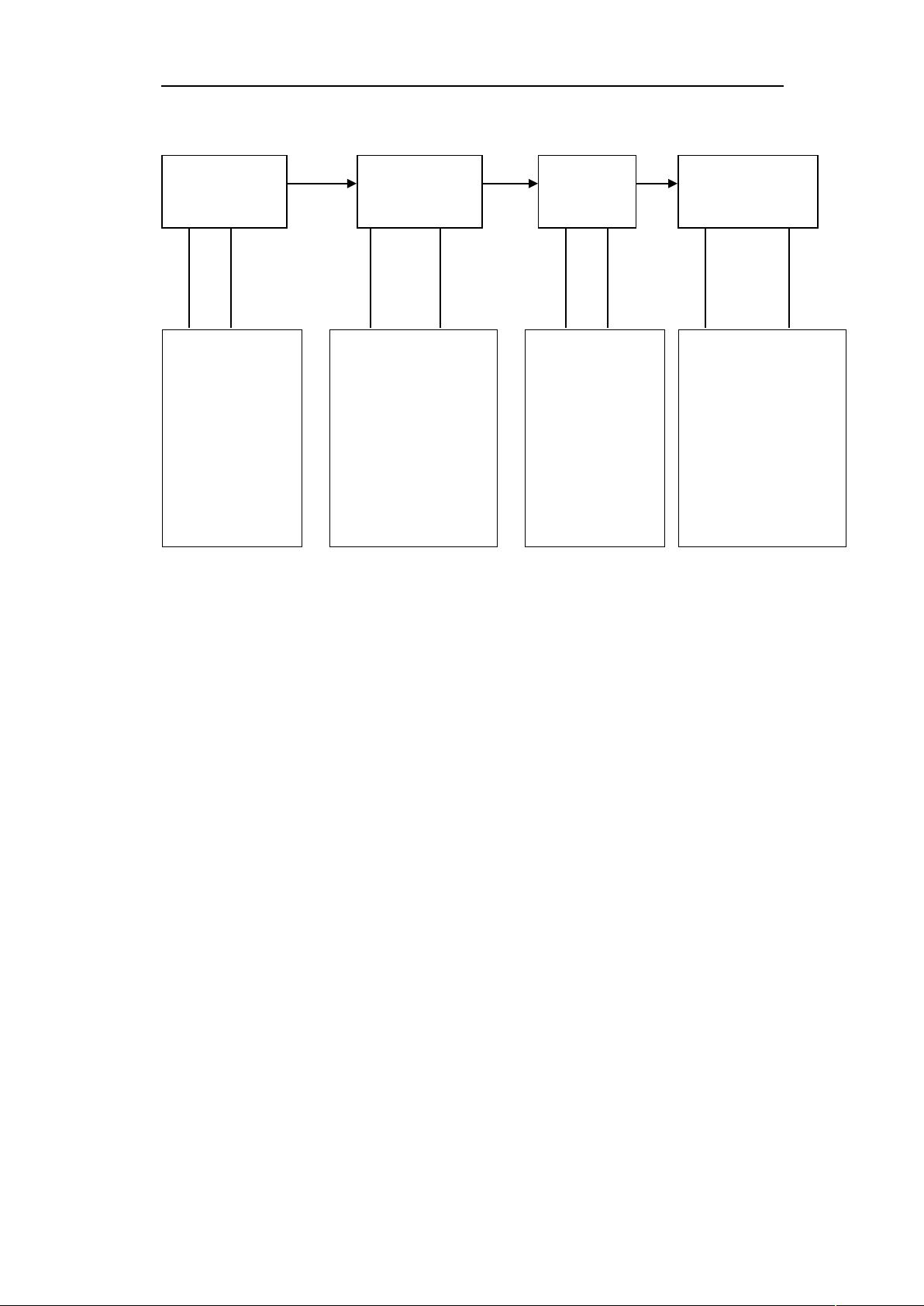

The design process of an injection mold involves analyzing the structural characteristics of the part, selecting appropriate materials, designing the gating and cooling systems, and determining the size and layout of the mold. In this project, the material for the plastic part was carefully chosen, the appropriate injection molding machine was selected, and the number of cavities and parting lines were determined. The design also included considerations for the mold frame size, gating system, ejector mechanism, mold release system, and temperature control system. Finally, simulation was conducted to ensure that the design met the requirements.

Overall, this project successfully achieved the design objectives for the injection mold. The key elements of the design including material selection, processing technology, and mold design were carefully considered and implemented to produce a high-quality injection molded part. This project demonstrates the importance of proper design and planning in the injection molding process to ensure the production of high-quality plastic components.

2021-08-23 上传

2023-09-22 上传

2022-04-27 上传

2024-05-27 上传

2024-04-07 上传

2023-05-28 上传

2023-05-09 上传

2023-05-27 上传

2024-04-07 上传

u010906448

- 粉丝: 0

- 资源: 1

最新资源

- 新型智能电加热器:触摸感应与自动温控技术

- 社区物流信息管理系统的毕业设计实现

- VB门诊管理系统设计与实现(附论文与源代码)

- 剪叉式高空作业平台稳定性研究与创新设计

- DAMA CDGA考试必备:真题模拟及章节重点解析

- TaskExplorer:全新升级的系统监控与任务管理工具

- 新型碎纸机进纸间隙调整技术解析

- 有腿移动机器人动作教学与技术存储介质的研究

- 基于遗传算法优化的RBF神经网络分析工具

- Visual Basic入门教程完整版PDF下载

- 海洋岸滩保洁与垃圾清运服务招标文件公示

- 触摸屏测量仪器与粘度测定方法

- PSO多目标优化问题求解代码详解

- 有机硅组合物及差异剥离纸或膜技术分析

- Win10快速关机技巧:去除关机阻止功能

- 创新打印机设计:速释打印头与压纸辊安装拆卸便捷性