基于PLC的自动配料系统设计与实践【实用文档】

177 浏览量

更新于2024-03-20

1

收藏 4.93MB DOC 举报

本文介绍了基于PLC的自动配料系统的设计和实现。自动配料系统是一种集输送、计量、配料、定量等功能于一体的动态计量系统,在建材、化工、冶金、矿山、电力、食品、饲料加工等行业中得到广泛应用。为了满足对自动配料系统中输送流量的精确调节和控制需求,本文设计了一套基于PLC的自动配料系统,并开发了触摸屏运行管理界面。

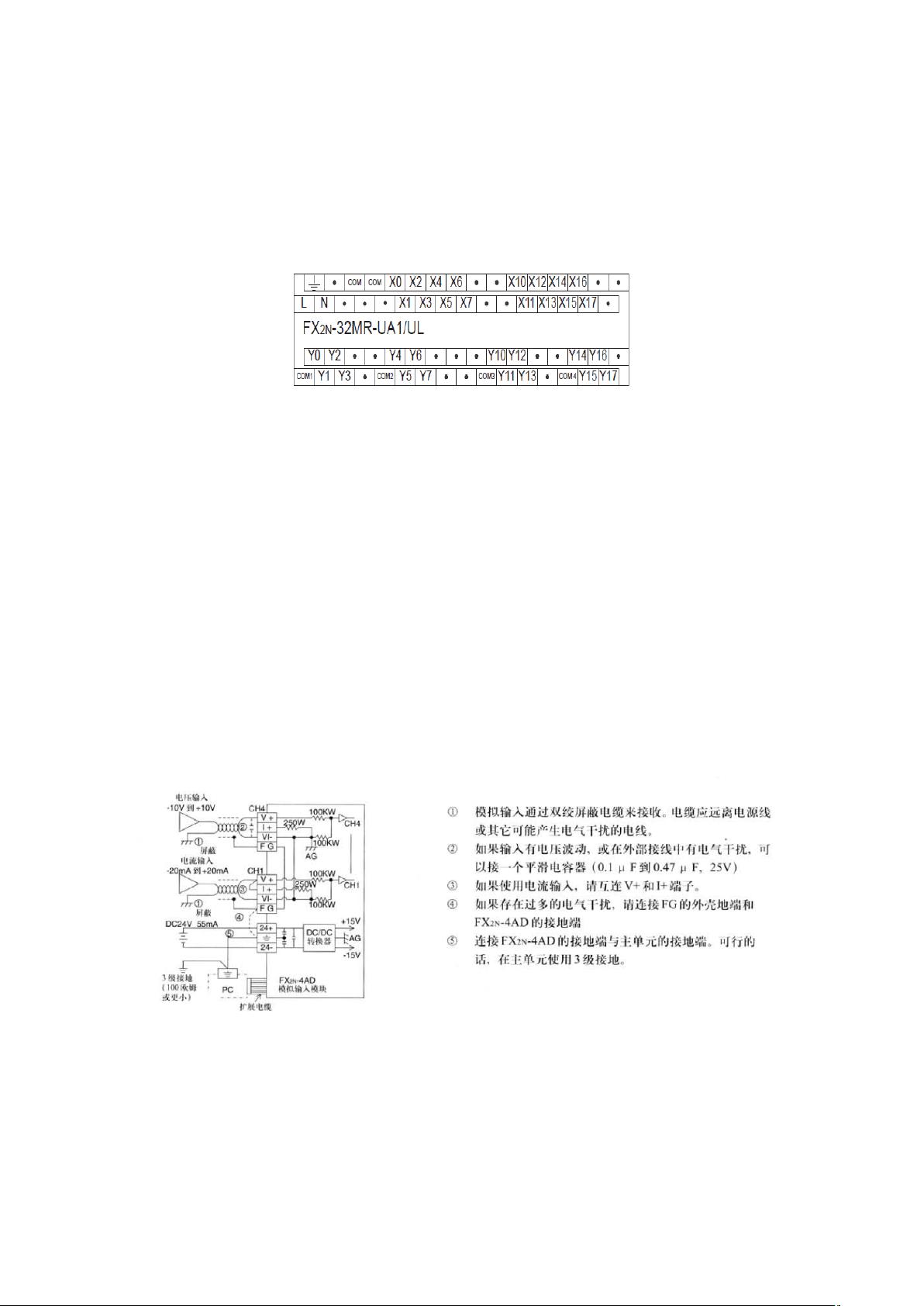

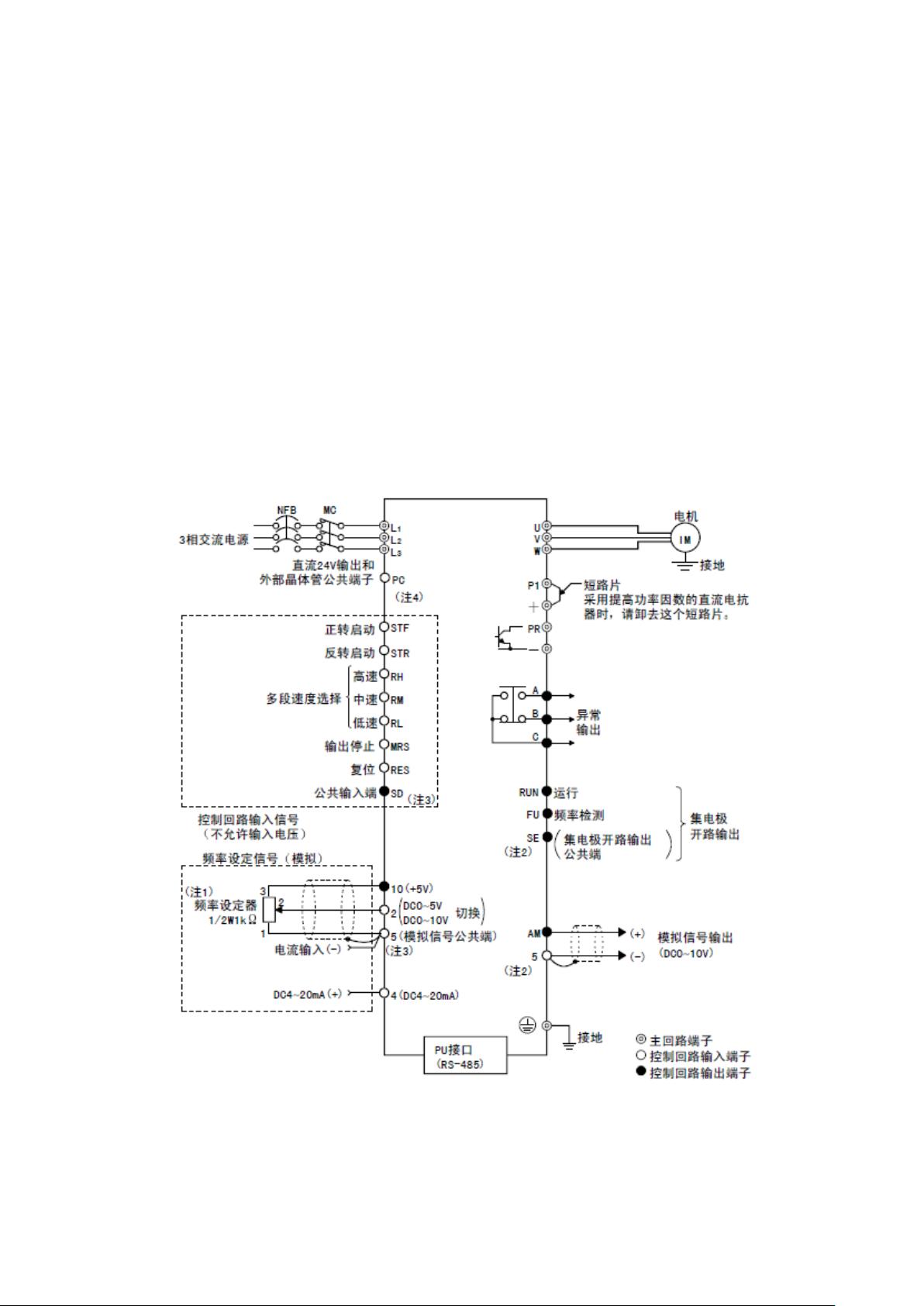

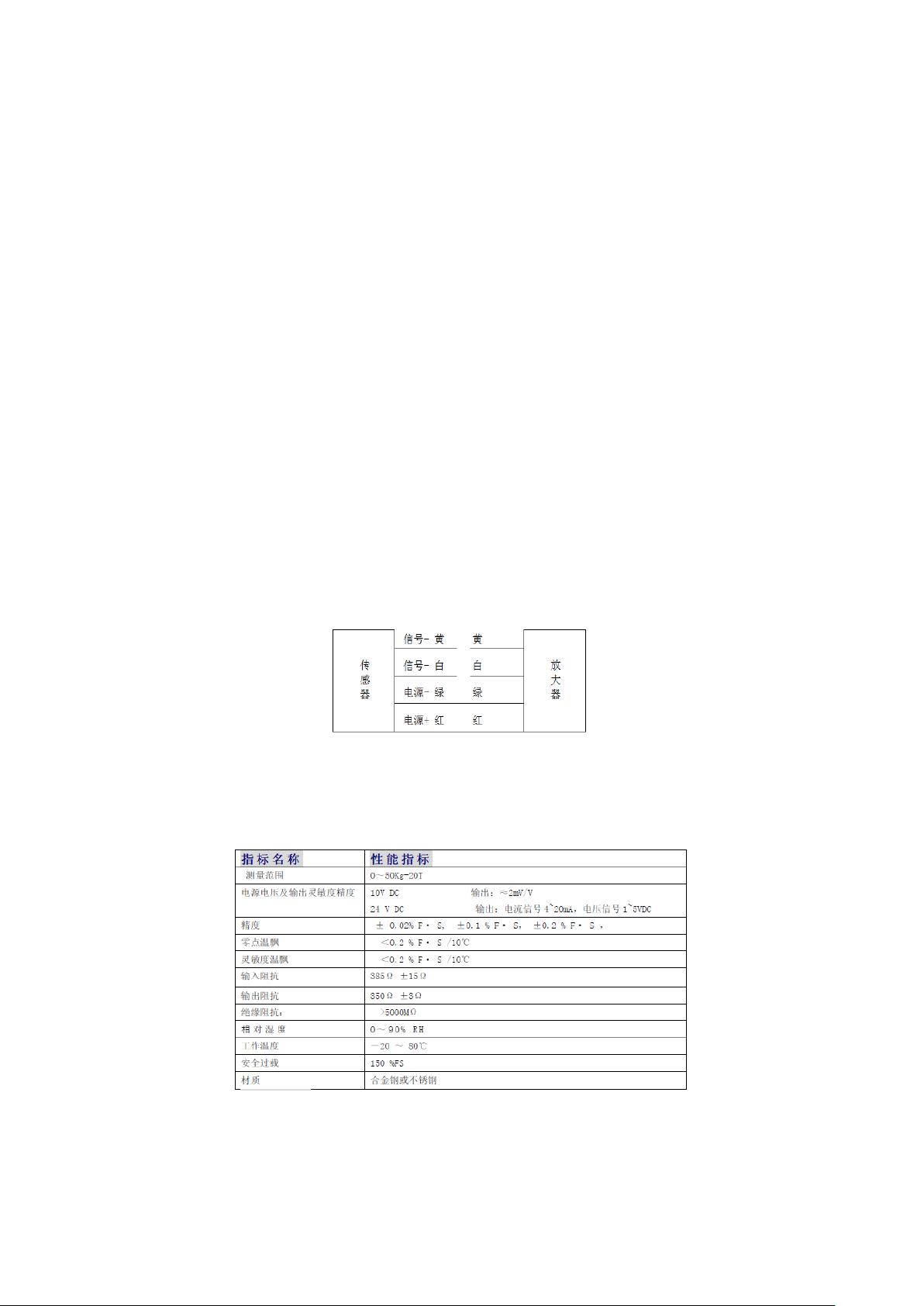

该自动配料系统由可编程控制器(PLC)、变频器、皮带驱动电动机、称重传感器等组成。系统包含三台皮带驱动电动机,根据需要依次启动。采用变频器实现对三相电动机的变频调速。称重传感器对物料进行称重并实时计量,PLC计算出实时流量及累计流量,通过PID调节改变输出信号以控制变频器对皮带驱动电动机的速度调节,实现恒流量控制,并对系统进行监控。

关键词:自动配料,变频调速,PID调节,PLC

Abstract:

This paper introduces the design and implementation of an automatic batching system based on PLC. The automatic batching system is a dynamic metering system that integrates functions such as transportation, measurement, batching, and quantification, and is widely used in industries such as building materials, chemical, metallurgy, mining, power, food, and feed processing. In order to meet the precise adjustment and control of the flow rate in the automatic batching system, this paper designs a set of automatic batching system based on PLC and develops a touch screen operation management interface.

The automatic batching system consists of a programmable logic controller (PLC), frequency converter, belt drive motor, weighing sensor, etc. The system includes three belt drive motors, which start sequentially as needed. The frequency converter is used to achieve variable speed control of the three-phase motor. The weighing sensor weighs the material and measures it in real time. The PLC calculates the real-time flow rate and cumulative flow rate. Through PID adjustment, the output signal is changed to control the speed regulation of the belt drive motor by the frequency converter, achieving constant flow control and monitoring the system.

Keywords: automatic batching, variable speed control, PID adjustment, PLC

相关推荐

yyyyyyhhh222

- 粉丝: 470

最新资源

- MIMO衰落信道容量分析与MATLAB仿真实现

- A*算法实践:物体寻路动画小游戏

- 利用MD5值快速终止进程并重命名文件

- PIC16F1829中文数据手册完整版下载

- 掌握Oracle XML Publisher创建Oracle报告技巧

- 项目稳定使用的DB2数据库jar包介绍

- Android实现简单音乐播放器及其登录注册功能

- BBQLinux Java Switcher 免费软件介绍

- 豆瓣Top250电影图书数据爬取指南

- 数字水印嵌入提取技术:DCT与SVD解析

- 中文版sniff抓包工具:界面简洁易用

- SDBoot烧写工具源码解压指南

- MES系统中HSMS开发专用SECS E37协议文档

- EkRTF报表控件:Delphi报表工具的简易制作方案

- Hippy框架介绍:Web前端跨端开发利器

- 先飞电脑技术网全站源代码下载及美化指南