AN155

8 Rev. 1.1

In contrast the linear-acceleration profile is much more

complex. A single fixed table cannot be used. The initial

conditions of each acceleration phase depend on the

length of all prior phases.

The recommended solution is to always start out using

a properly implemented linear-velocity profiler. This will

be the best solution for most applications. Verify that the

velocity is actually linear and evaluate the dynamic

response of the system. If the dynamic response of the

system does not meet the requirements, consider using

a linear-acceleration profile.

3.8. Interrupt Based Algorithm

When developing an algorithm to control a stepper

motor using a small microcontroller, it is important to

consider the manner in which the code will be executed.

A simple sequential algorithm could accomplish the

task. The sequential algorithm might calculate the

current step time and figure out what to do next

depending on the acceleration phase. However, such

an algorithm would end up writing to the timer and then

waiting until the timer times out. It would spend most of

the time just waiting on the timer.

Fortunately most MCU timers are capable of generating

interrupts. Thus, we can set up the timer to generate an

interrupt after one step period. When the interrupt

occurs, the MCU should commutate the motor and

update the timer with the next step period.

Now considering that we want to make the stepper

motor control interrupt based, we must use a different

paradigm. The timer interrupt service routine should be

small, fast, robust, and only do what must be done on

each commutation period. Anything that can be

calculated once beforehand will be done outside the

interrupt service routine. Values may be stored in global

variables to be accessed by the interrupt service

routine.

Using this scheme there are two basic pieces of code.

The first is the profiler or the move() function. The

second is the timer interrupt service routine. The profiler

is called from the main loop and is executed in the

foreground. The profiler calculates the global variables

based on the target location and the current position of

the motor. The function is named move() so that the

user code makes sense in plain English.

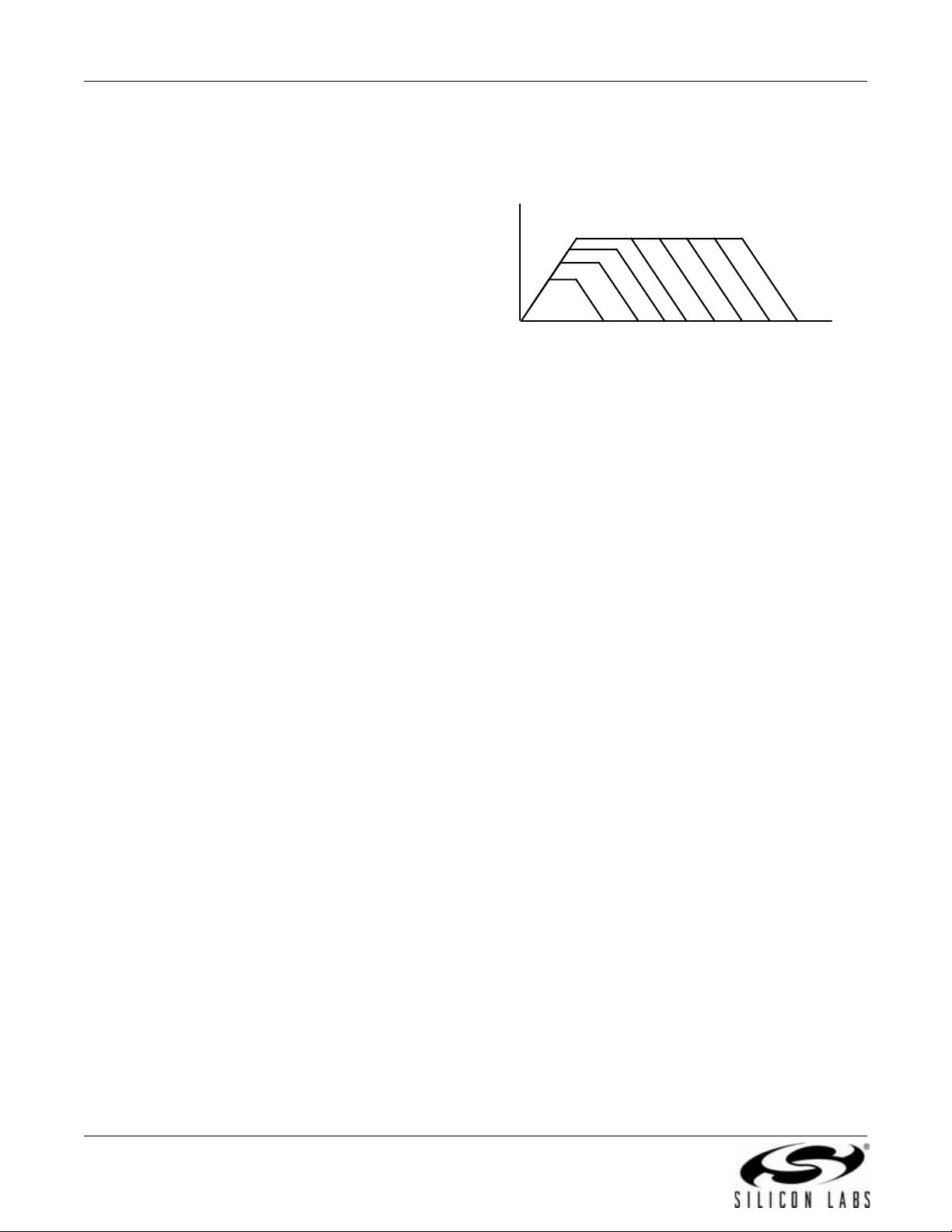

This reference design uses a simple divide-by-four

profiler. This means that the total number of steps is

divided by four. The motor will accelerate and

decelerate for one forth of the total number of steps.

The remainder of the steps will be at a constant velocity.

Some actual profiles are shown in Figure 5. Note that

the total time accelerating for short profiles is much

more that one-forth the total time. This is due to the

effect of the variable step period.

The constant-acceleration and deceleration phases are

accomplished by incrementing and decrementing an

index for the stepper motor table. Incrementing the table

index by one each step will accelerate the motor.

Decrementing the index each step will decelerate the

motor. The maximum index and the corresponding

minimum period determine the top speed of the motor

for a particular profile.

4. Hardware Design

The Stepper motor reference design hardware consists

of four sections: the C8051F300 microcontroller, the

power electronics, the voltage regulator, and the serial

interface. The full schematic is included in Appendix A.

The Bill of Materials is in Appendix B and the printed

circuit board artwork is in Appendix C.

4.1. Microcontroller

The reference design features the C8051F300

microcontroller. This microcontroller is housed in a tiny

3 mm by 3 mm 11-lead micro lead package (MLP). This

package is small enough to be integrated into the

smallest motor. The C8051F30x family includes five

devices with various options. The ‘F300 and ‘F301

include a calibrated internal oscillator. The internal

oscillator is calibrated to within

±2% at test. This is

close enough to use the internal oscillator for the UART

with baud rates up to 115.2 kbps. The reference design

does not utilize 8-bit 500 ksps ADC in the ‘F300. Thus,

the design could use either the ‘F300 or the ‘F301 which

does not include the ADC. The ADC on the F300 might

prove useful in some designs for monitoring the dc

motor voltage, stepper motor current, or the stepper

motor temperature.

The unipolar stepper motor drive requires four outputs

to drive the transistors. P0.0 through pin P0.3 are used

to drive the power MOSFETs. The pins have been

ω

τ

ω

time

Figure 5. Different Profiles