Scaling and Bandwidth-Parameterization Based

Controller Tuning

Zhiqiang Gao

Dept. of Electrical and Computer Engineering

Cleveland State University, Cleveland, Ohio 44115

Abstract: A new set of tools, including controller scaling,

controller parameterization and practical optimization, is

presented to standardize controller tuning. Controller scaling is

used to frequency-scale an existing controller for a large class of

plants, eliminating the repetitive controller tuning process for

plants that differ mainly in gain and bandwidth. Controller

parameterization makes the controller parameters a function of a

single variable, the loop-gain bandwidth, and greatly simplifies

the tuning process. Practical optimization is defined by

maximizing the bandwidth subject to the physical constraints,

which determine the limiting factors in performance.

Collectively, these new tools move controller tuning in the

direction of science.

Keywords: Tuning, PID, Scaling, Auto-Scaling, Auto-Tuning,

Adaptive Self-Tuning, Gain-Scheduling, Disturbance Observer,

Computer Aided Controller Design

I.

Introduction

The proportional-integral-derivative (PID) controller, first

proposed by N. Minorsky in 1922 [1], is used in over 90% of

current industrial control applications [2]. In addition, the

controller parameters are still determined by rules of thumb, such

as look-up tables [3].

Classical control theory has successfully provided the analysis

and design tools for single-input single-output (SISO), linear,

time-invariant systems, since the 1940s. The PID design

approach moved from empirical (i.e., ad hoc tuning methods such

as Ziegler and Nichols tuning tables [3]) to analytical (i.e., pole

placement, frequency response). In particular, the frequency

response-based methods (Bode and Nyquist plots, stability

margins, lead-lag compensators) have proved to be especially

useful in solving control problems.

Historically, determining controller parameters to meet design

specifications (tuning

), rather than the design of the controller

itself, has been the main concern in industry. Most industrial

plants are inherently stable and consist of SISO subsystems.

Simple PID controllers implemented in a digital form can usually

meet the performance needs. But the problem of tuning has

hardly received much attention in the existing control theory. The

variety of ad-hoc tuning algorithms in industrial control products

shows the lack of in-depth understanding of the problem and the

need for further research.

The PID gains are commonly “tuned” on a trial-and-error basis in

practice. A general lack of knowledge regarding the relationship

between “design objectives” and “practical performance

measures” makes the use of well-known design techniques such

as Root Locus (pole-placement) and linear optimal control

difficult. For example, in pole-placement design, the objective is

to place the closed-loop poles at given locations, based on the

understanding of how the location of poles affects the transient

response of a system. Although the transient response is usually

an important design consideration, it is not the only issue in pole-

placement methods with which to contend. The pole-placement

method is ill-equipped to handle other common design

specifications including disturbance rejection, noise sensitivity,

stability margins, and smoothness of the control signal.

This lack of design insight leads to the heuristic nature of the

tuning methods implemented in industry. Furthermore, the

practice of control design and tuning tended in the direction of art

rather than science. This paper presents a comprehensive

approach that moves control design and tuning in the direction of

science.

The paper is organized as follows. Controller scaling is

introduced in Section II. Parameterization and optimization of

model-based controllers are discussed in Section III. Design,

parameterization, and optimization of a model-independent

controller design method are discussed in Section IV. Finally,

some concluding remarks are given in Section V.

II. Controller Scaling

A controller is generally not “portable”, i.e., a controller designed

for one plant is usually not applicable to another plant. The

objective of controller scaling is to make a good controller

“portable”, much like the filter design. With the bandwidth, pass

band, and stop band requirements given, the filter design is

straightforward. First, a unit bandwidth filter, such as an nth

order Chebeshev filter H(s), is found that meets the pass band and

stop band specifications; then it is frequency scaled by ω

0

to

achieve the desired bandwidth of ω

0

. It is shown in this section

that the controller design can be performed similarly.

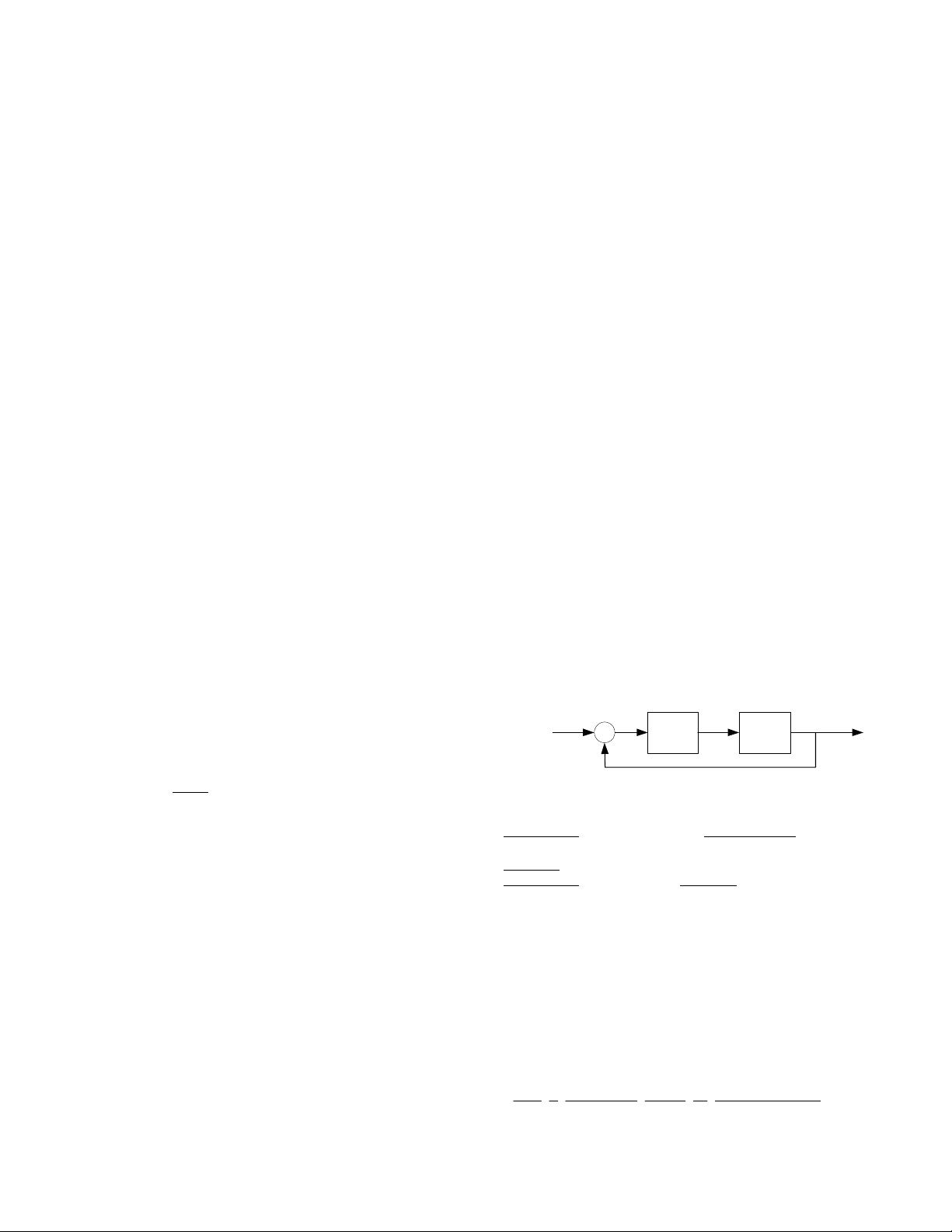

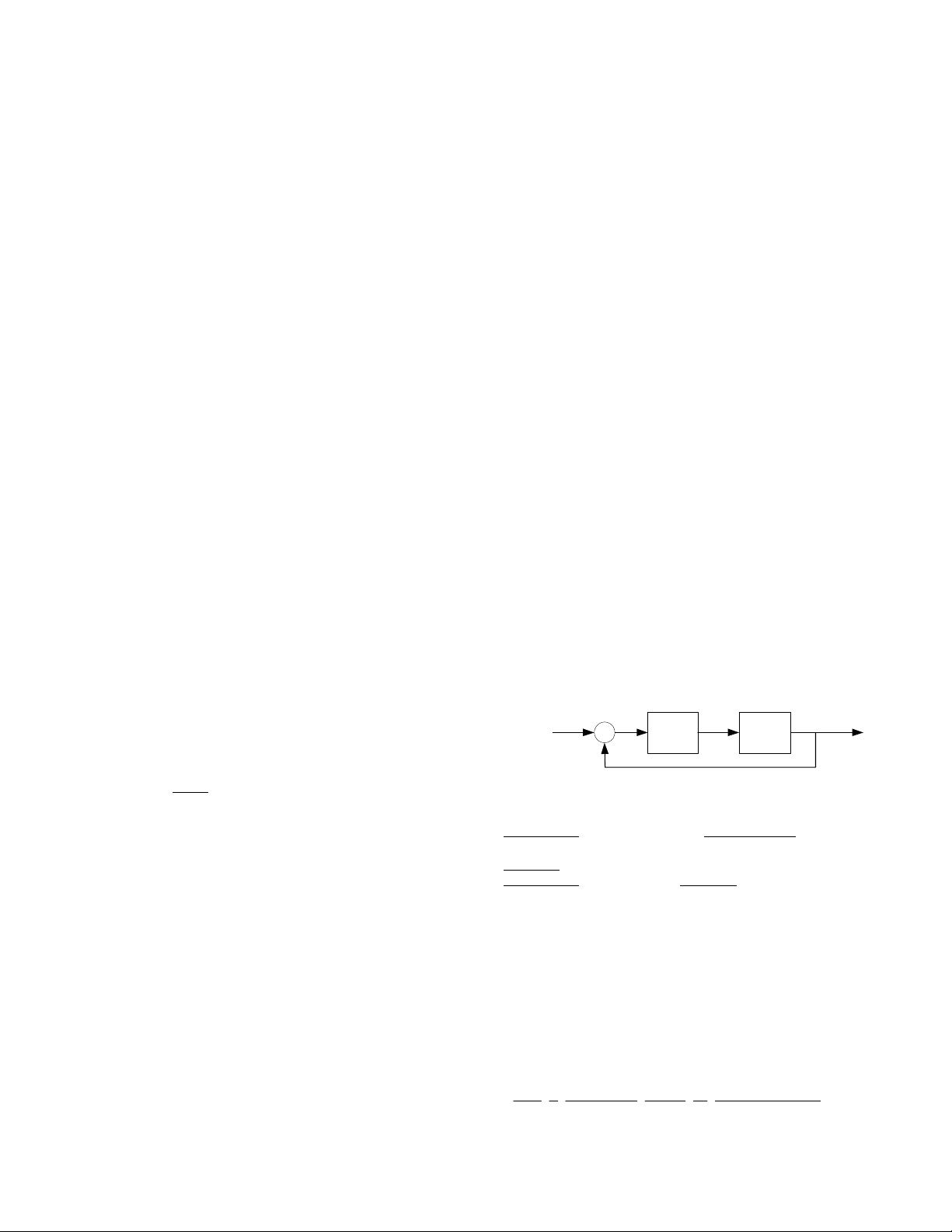

2.1 Frequency Scale and Time Scale

Consider a unit feedback control system with the plant G

p

(s) and

the controller G

c

(s), as shown in Figure 2.1. Assume that G

c

(s)

was designed for desired command following, disturbance and

noise rejection, and stability robustness. Now, consider a similar

class of plants G

p

(s/ω

p

), for any given

ω

p

. Can a controller be

found without a repetition of the tedious loop shaping design

process?

(s)

-

(s)

r

ye

reference

input

output

G

c

G

Figure 2.1 Feedback Control Configuration

Definition2.1

: Denote

ω

p

as the frequency scale of the plant

G

p

(s/

ω

p

) with respect to G

p

(s), and

τ

p

=1/

ω

p

, the corresponding

time scale

.

Definition2.2

: Denote k as the gain scale of the plant kG

p

(s) with

respect to G

p

(s).

The differences in many industrial control problems can be

described in terms of the frequency and gain scales defined here,

such as the temperature processes with different time constants (in

first-order transfer functions), motion control problems with

different inertias, motor sizes and frictions.

The use of the scales allows the development of a generic solution

for a class of problems. Any linear time-invariant plant, strictly

proper and without a finite zero, can be reduced to one of the

following forms

2232

12

11 1 1 1 1

, , , , , , ...

121s(s+1)s 1sss s ss s

ξξξ

+++ +++

(2.1)

0-7803-7896-2/03/$17.00 ©2003 IEEE 4989

Proceedings of the American Control Conference

Denver, Colorado June 4-6, 2003