"组合机床滑台及底座设计与主轴组件研究"

7 浏览量

更新于2024-03-24

收藏 484KB DOC 举报

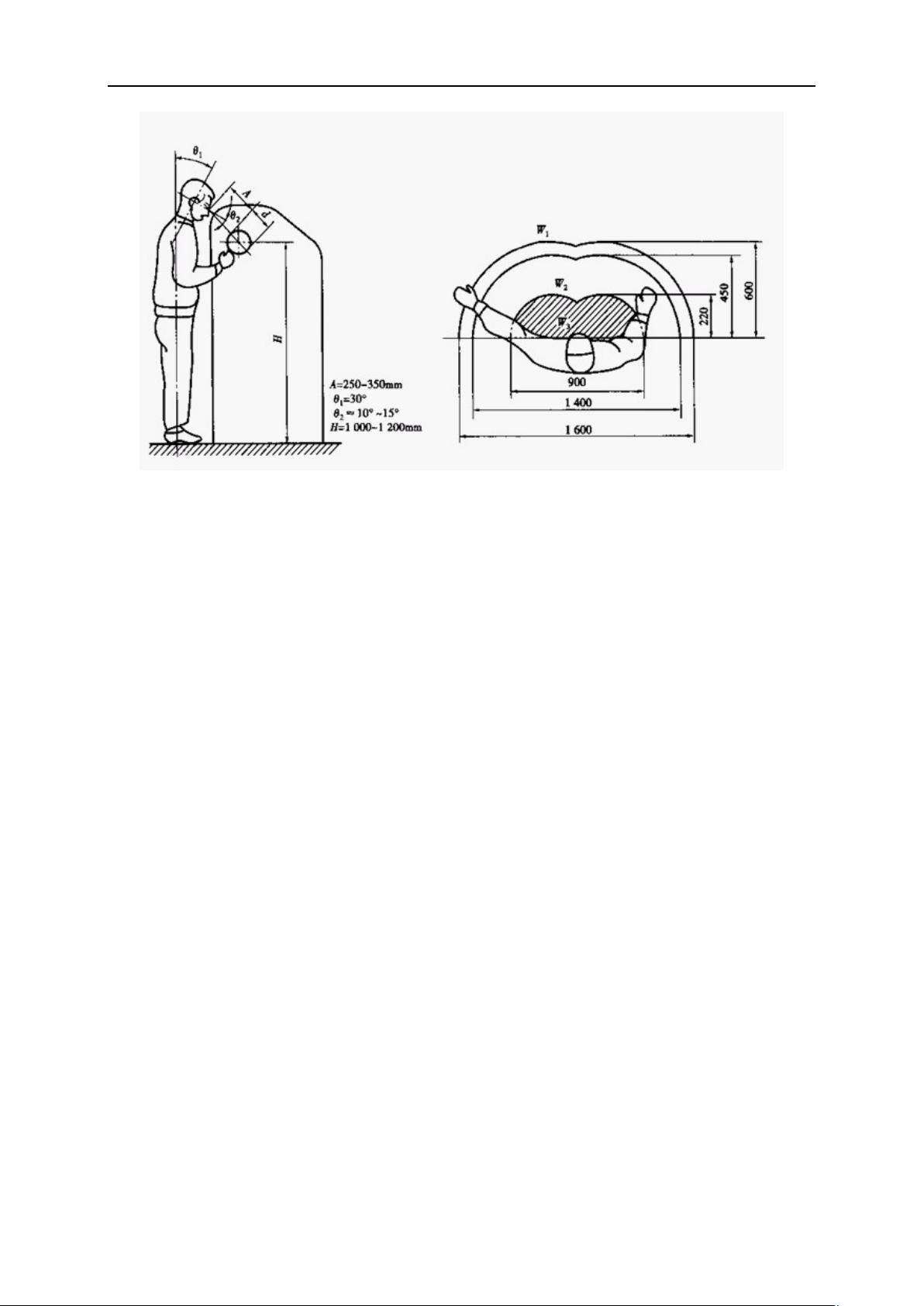

The content discusses the design of the slide table and base of a combination machine tool for the machining process of the six holes on the flange on the rear axle shaft of a tracked tractor. It primarily focuses on the design of the guide rails, support components, and the spindle assembly, including the design of the support components such as the slide table, slide table body, and slide table seat. The overall layout of the machine tool determines the various components of the machine. The guide rail design includes the selection of guide rail types, determination of cross-sectional shape, structural dimensions, pressure testing, material selection and heat treatment, lubrication and protection devices, and technical requirements for guide rail manufacturing. The design of support components involves determining the minimum wall thickness, partition plates and reinforcement ribs, material selection and aging treatment, the rationality of process structure, and size determination. The spindle assembly design includes spindle drive, determination of spindle diameter, lubrication and sealing, selection of spindle rolling bearings, determination of spindle box profile dimensions, and design of the spindle box transmission system. The key words include combination machine tool, spindle box, slide table, guide rail, support components, and spindle assembly.

2023-06-28 上传

2023-07-10 上传

2021-09-29 上传

matlab大师

- 粉丝: 2738

- 资源: 8万+

最新资源

- WordPress作为新闻管理面板的实现指南

- NPC_Generator:使用Ruby打造的游戏角色生成器

- MATLAB实现变邻域搜索算法源码解析

- 探索C++并行编程:使用INTEL TBB的项目实践

- 玫枫跟打器:网页版五笔打字工具,提升macOS打字效率

- 萨尔塔·阿萨尔·希塔斯:SATINDER项目解析

- 掌握变邻域搜索算法:MATLAB代码实践

- saaraansh: 简化法律文档,打破语言障碍的智能应用

- 探索牛角交友盲盒系统:PHP开源交友平台的新选择

- 探索Nullfactory-SSRSExtensions: 强化SQL Server报告服务

- Lotide:一套JavaScript实用工具库的深度解析

- 利用Aurelia 2脚手架搭建新项目的快速指南

- 变邻域搜索算法Matlab实现教程

- 实战指南:构建高效ES+Redis+MySQL架构解决方案

- GitHub Pages入门模板快速启动指南

- NeonClock遗产版:包名更迭与应用更新