COL 10(4), 041405(2012) CHINESE OPTICS LETTERS April 10, 2012

Graphene-based Q-switched pulsed fiber laser in a linear

configuration

Y. K. Yap

1

, Richard M. De La Rue

1

, C. H. Pua

1

, S. W. Harun

2

, and H. Ahmad

1

1

Photonics Research Centre, Department of Physics, Faculty of Science, University of Malaya, Kuala Lumpur, Malaysia

2

Department of Electrical Engineering, Faculty of Engineering, University of Malaya, Kuala Lumpur, Malaysia

∗

Corresp onding author: yapyuenkiat@yahoo.com

Received August 30, 2011; accepted October 25, 2011; posted online January 6, 2012

A pulsed laser system is realized with graphene employed as a Q-switch. The graphene is exfoliated from

its solution using an optical deposition and the optical tweezer effect. A fiber ferrule that already has

the graphene deposited on it is inserted into an erbium-ytterbium laser (EYL) system with linear cavity

configuration. We successfully demonstrate a pulsed EYL with a pulse duration of approximately 5.9 µs

and a repetition rate of 20.0 kHz.

OCIS codes: 140.3540, 140.3538.

doi: 10.3788/COL201210.041405.

Graphene, an allotrope of carbon whose structure is one-

atom-thick planar sheets of sp

2

-bonded carbon atoms

densely packed in a honeycomb crystal lattice (i.e., con-

sisting of a hexagonal array of sp

2

-bonded carbon atoms

similar to those found in bulk graphite) is currently a

major research topic of interest due to its uniqueness

as a two-dimensional (2D) material. Bonaccorso et al.

presented a detailed description on various aspects of

graphene as well as its many possible applications in

photonics and optoelectronics, where the combination of

its unique optical and electronic properties could be fully

exploited in the absence of a bandgap

[1]

. The linear dis-

persion of the Dirac electrons in graphene allows for ultra

wideband tunability

[1]

. Its thin dimension and electronic

properties make it suitable for electronic devices such

as transistors and gas sensors. Graphene’s resistivity to

acids and alkalines provides an opportunity for its use

in inert coatings as well. In optoelectronics, its special

optical properties enable graphene to have an ultrashort

recovery time in saturation absorption. In addition, it

displays smaller non-saturable loss and a higher damage

threshold. The unique absorption of light by graphene

can become saturated when the input optical intensity is

above a specific threshold value. Graphene can be read-

ily saturated under strong excitation over the visible to

near-infrared region due to the universal optical absorp-

tion resulting from the zero band-gap structure. This be-

havior is relevant for the mode-locking and Q-switching

of fiber lasers, where short pulses have been achieved by

using graphene-based saturable absorb ers

[2−6]

. The first

mode-locked laser in a ring configuration was reported

by Hasan et al.

[7]

, whose research observed saturation

absorption over at least a 20-nm range with a pulse

duration of ∼800 fs. Using graphene as a saturable ab-

sorber, Sun et al. successfully produced a mode-locked

pulse train at a repetition rate of 19.9 MHz from a ring

erbium-doped fiber laser (EDFL)

[8]

. Graphene has also

been used to mitigate the mode competition in EDFLs

as well as stabilize the multi-wavelength oscillation

[9]

.

In this letter, we describe the successful production of a Q-

switched pulsed laser using graphene inserted into a laser

oscillation system within a linear cavity configuration.

Thus far, as optical pulse generation by graphene has

been reported primarily in a ring laser configuration,

this device is, to the best of our present knowledge, the

first ever Q-switched pulsed fiber laser using graphene

achieved in a linear laser cavity configuration. One mo-

tivation of the present work is to propose a simple and

efficient setup for short pulse generation (i.e., mode-

locked operation) in a linear configuration.

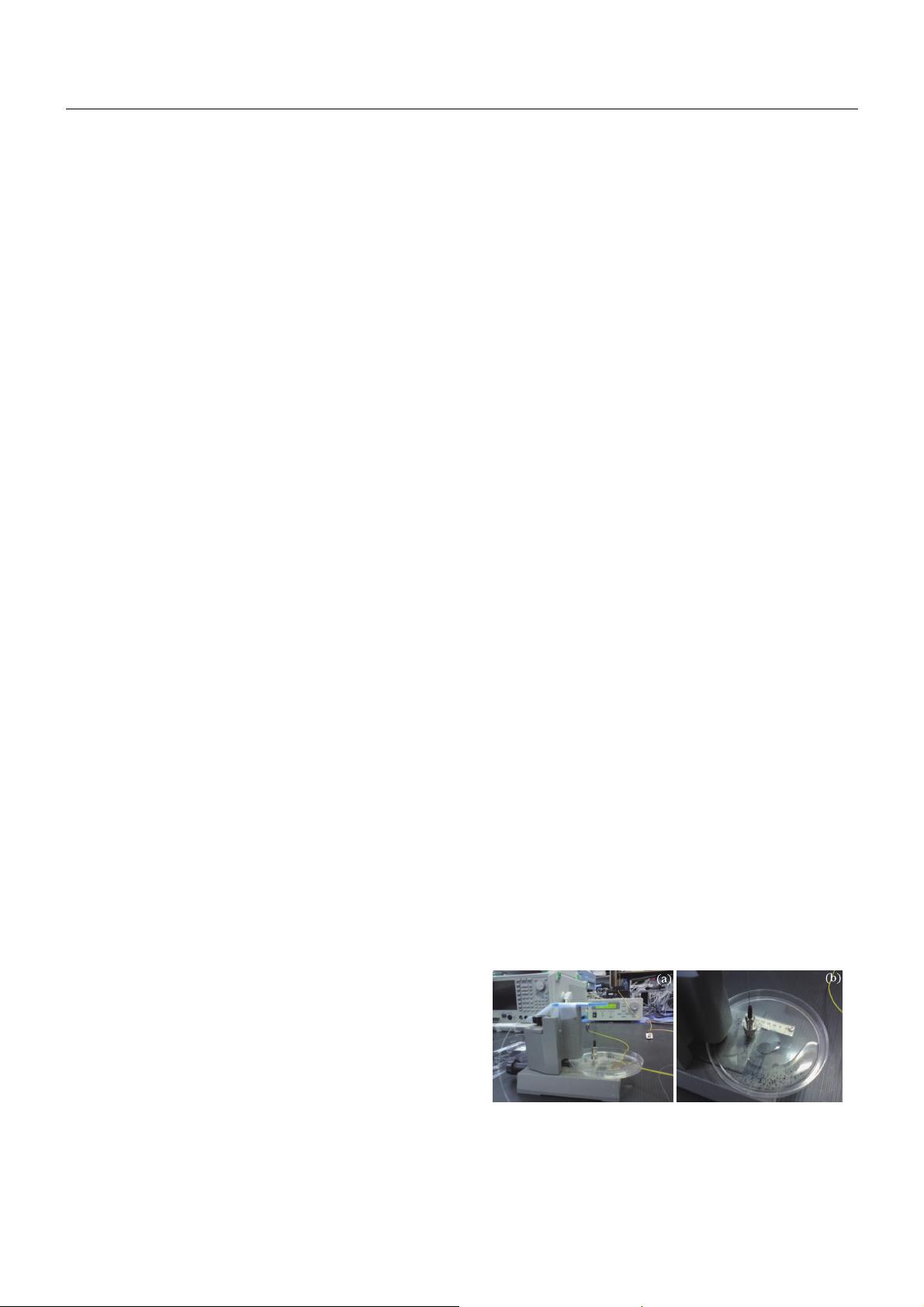

The graphene flakes (in a solution) used in this research

were supplied by Graphene Research. The graphene had

to be deposited onto a fiber ferrule; we employed the

optical tweezer effect for this purpose. The setup for de-

positing graphene onto the fiber ferrule is shown in Fig.

1. The fiber was prepared by removing the PVC coating,

cleaving, and then placing it into the solution. Optical

radiation from a 980-nm laser diode (LD) at 10 dBm was

then propagated through the fiber; the laser was left on

for 30 min. The laser beam has a very high intensity;

therefore, at the end face of the fiber ferrule, it produces a

very strong electric field gradient, resulting in the attrac-

tion of the graphene flakes along the field-gradient into

the region of the strongest electric field. The laser beam

exerts a force on the flakes that are in the beam, along

the direction of beam propagation. The LD was then

turned off, and the fiber was removed from the solution.

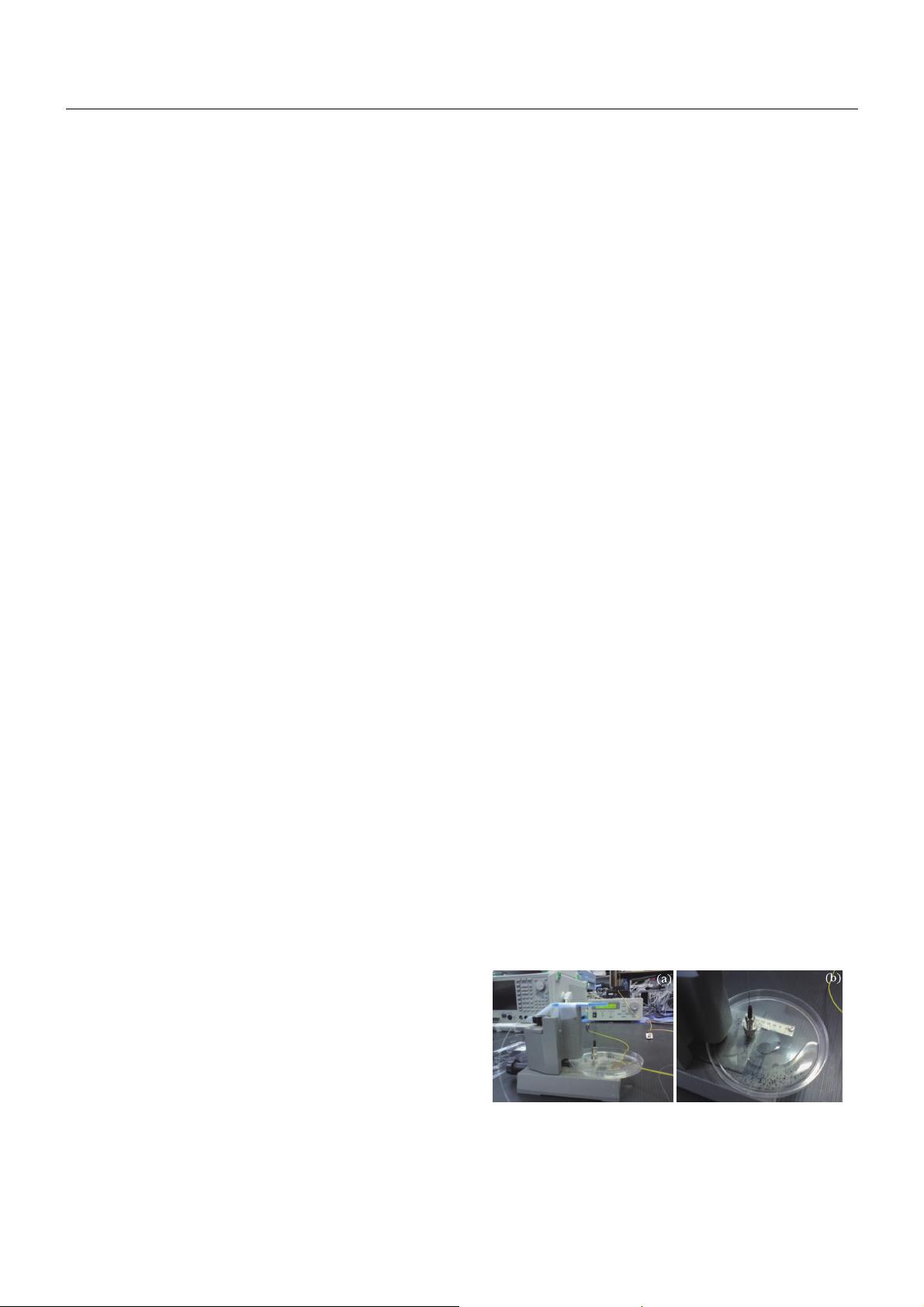

Fig. 1. (a) Experimental setup for deposition of graphene onto

the end face of the fiber ferrule; (b) graphene flakes could be

clearly seen in the solution. The flakes were deposited onto

the ferrule by an attractive force caused by the gradient of

the strong electric field near the end of the ferrule.

1671-7694/2012/041405(4) 041405-1

c

° 2012 Chinese Optics Letters