April 10, 2009 / Vol. 7, No. 4 / CHINESE OPTICS LETTERS 319

Silicon nanocrystals to enable silicon photonics

Invited Paper

Min Xie

∗

, Zhizhong Yuan, Bo Qian, and Lorenzo Pavesi

Nanoscience Laboratory, Department of Physics, University of Trento, Via Sommarive 14, I-38100 Povo (Trento), Italy

∗

E-mail: nllab@science.unitn.it

Received January 7, 2009

Low dimensional silicon, where quantum size effects play significant roles, enables silicon with new photonic

functionalities. In this short review, we discuss the way that silicon nanocrystals are prod uced, their

optoelectronic properties and a few device applications. We demonstrate that low dimensional silicon is

an optimum material for developing silicon photonics.

OCIS codes: 160.4236, 190.4400, 200.4650, 250.3140.

doi: 10.3788/COL20090704.0319.

1. Introduction

Silicon photonics is the technology where photonic de-

vices are pr oduced by standard microe le c tronics pro-

cesses by using the same paradigm of electronics: in-

tegration of a large number of devices to yield a high

circuit complexity which allows high per fo rmances and

low costs

[1]

. Thus, the real truth is to develop photonic

devices that can be easily integrated to improve the

single device performance and to allow high volume pro-

duction: integration and mass-manufacturing ar e where

silicon photonic can outperform other photonic plat-

forms, such as InP-based or glass-based ones. To this

aim, one further add-on is making silicon do something

where it is not able to do in its standard (bulk) form.

Low dimensional s ilicon, where small silicon nanocrys-

tals or na noclusters (Si-ncs ) are developed, is one way to

compel silicon to act as an active optical material

[2]

. In

this short review, we will go through a few applications

where Si- nc enables silicon doing photonic functions oth-

erwise not possible by using bulk silicon.

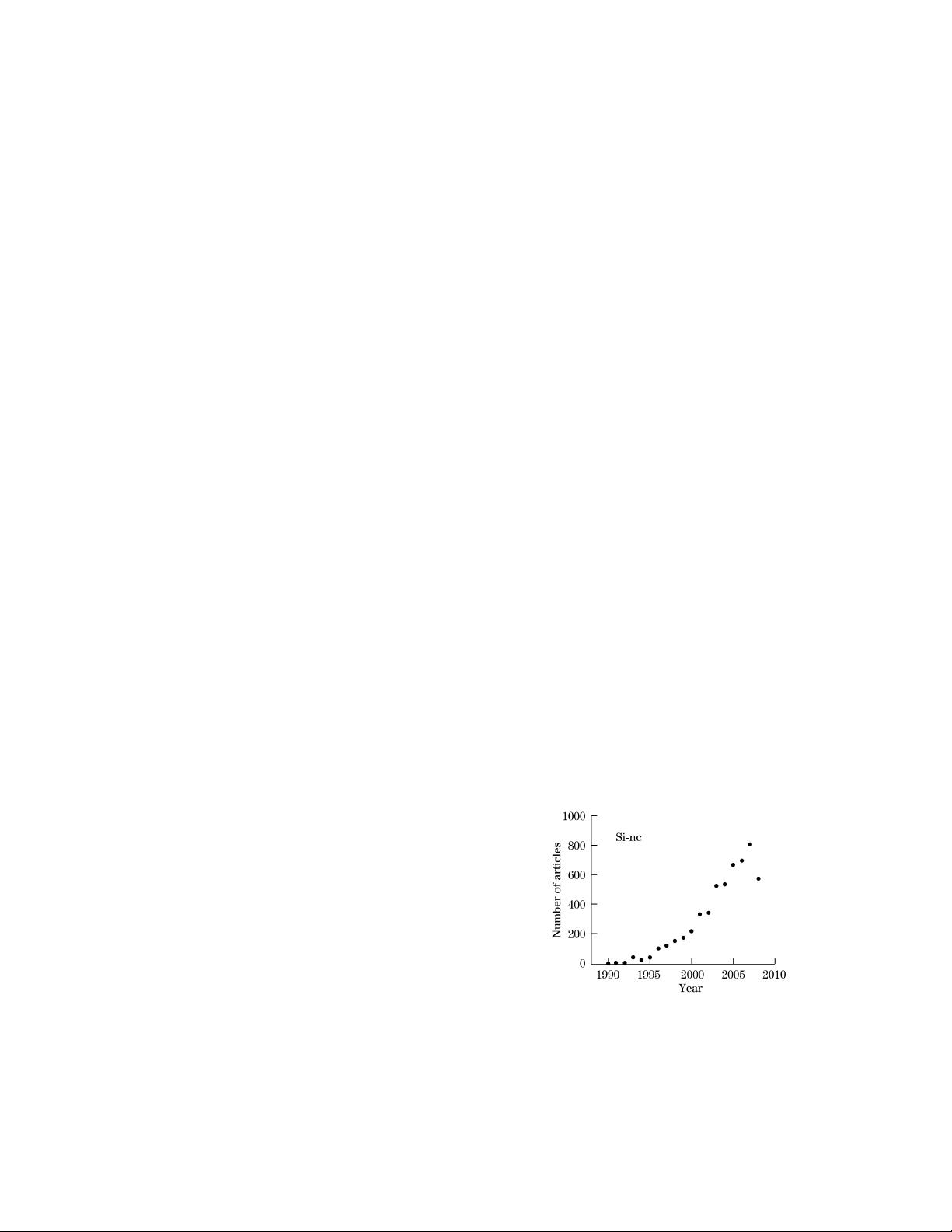

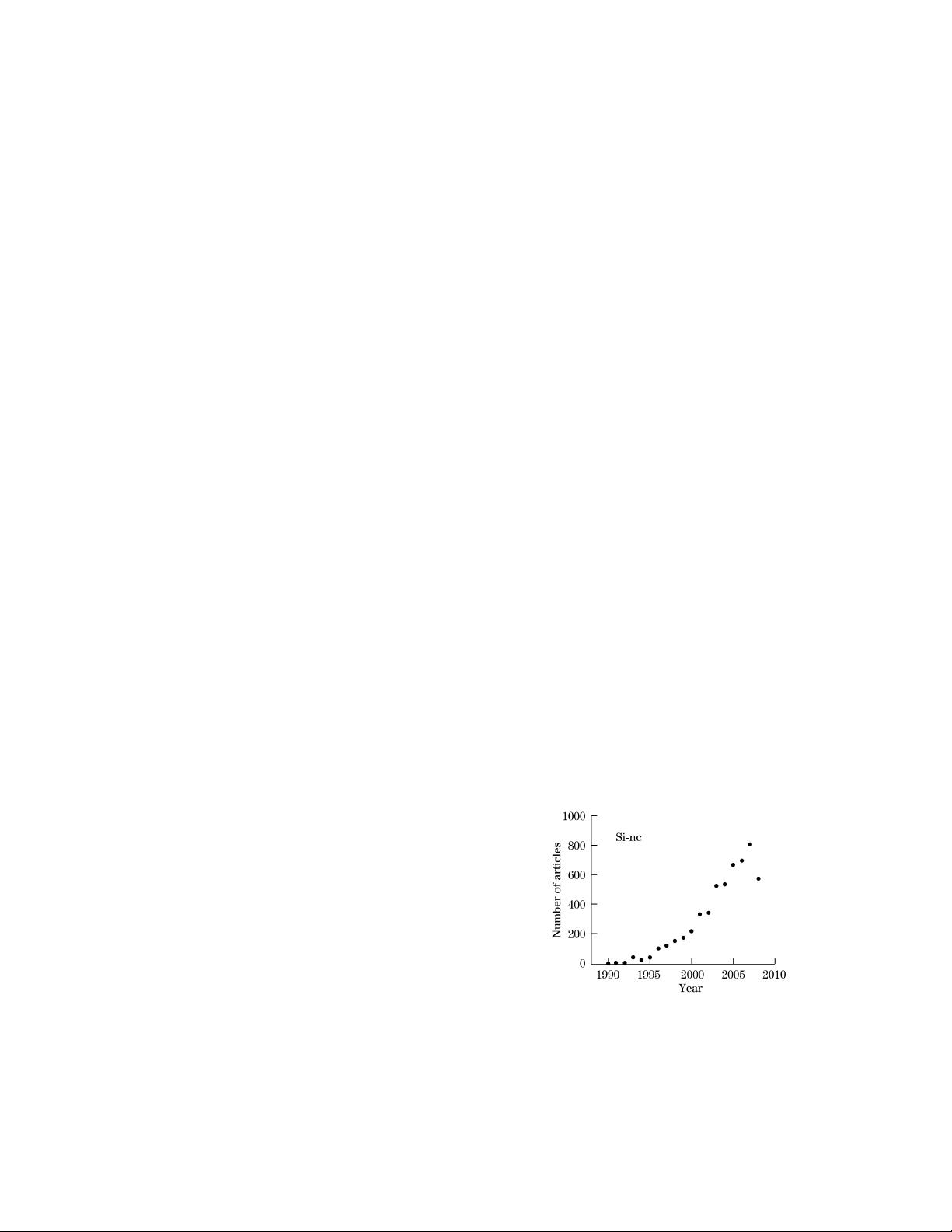

Figure 1 reports the number of results one gets if looks

for Si-nc in Google

TM

Scholar. It is obse rved a steady

rise in the numb e r of publications witnessing the ris-

ing interest in this material. The first results found in

this search refer to four papers reporting about differ-

ent properties of Si-nc: the first is our paper on the

observation of optical gain

[3]

, the second is the pa per

by Tiwari et al. on the use of Si-nc for memor ie s

[4]

, the

third is the paper by Wilson et al. on the demonstration

of quantum size effects in Si-nc

[5]

, and the fourth is the

paper by Mutti et al. on the observation o f room tem-

perature luminescence in Si-nc

[6]

. While if one makes the

same search on Google

TM

, the first result concerns the

use of Si-nc for photovoltaics

[7]

. All the key ingredients

that make Si-nc appealing for photo nics are discussed in

these papers: quantum s iz e effects make new phenom-

ena appear in silicon, such as r oom temperature visible

photoluminescence, optical gain, Coulomb blockade, and

multiexciton generation. In this short review, we will

discuss these topics and see how they can be exploited in

working devices. For more detailed information, we refer

readers to o ther reviews tha t we wrote in the past

[8−11]

.

2. Silicon nanocrystals: production

Silicon nanocrystals are produced by a wealth of dif-

ferent techniques

[12]

. They can be essentially distin-

guished into three types: direct synthesis, phase separ a-

tion in a silicon-rich dielectric, and top-down production

from bulk silicon. Examples of the first type are cluster

deposition

[13]

or chemical synthesis in a solution

[14]

. The

second class of techniques is mor e widely diffused and

essentially is bas e d on the production of a silicon-rich

dielectric (e.g., silicon oxide or silicon nitride) and on the

phase separation of the constituent phases (silicon and

the dielectric) by an annealing treatment. The duration

and temp e rature of the annealing treatment determine

the size and crystallinity of the nanoparticles. Various

methods can be use d to produce the starting silicon-rich

dielectric: ion implantation

[6]

, sputtering

[15]

, chemical

vapor deposition (CVD)

[16]

, so l-gel synthesis

[17]

, etc.

The third clas s of techniques is the one us ed in the pro-

duction of porous silicon (electrochemical etching) where

silicon is partially dissolved and the remaining skeleton

is composed of interconnected Si-ncs

[18]

. Alternatively,

lithographic technique followed by rep e ated oxidations on

a silicon wafer can define small silico n islands or columns

where Si-ncs are formed

[19]

. This is useful for single Si-

nc production, or when the geo metr ical arrangement of

Si-nc has to b e controlled.

The preparation method strongly influences electrical

Fig. 1. Number of articles versus year as reported by

Google

TM

Scholar in a search performed on 31/12/2008.

The search keys were “low dimensional silicon” OR “silicon

nanocrystal/s” OR “silicon nanocluster/s”. The total num-

ber of articles integrated over the years is 6220, while the

results for “silicon photonics” is 1740 and for “porous sili-

con” is 28800. The single point referred to year 2008 is low

due to the time delay between the search date and the actual

database construction.

1671-7694/2009/040319-06

c

2009 Chinese Optics Letters