Temperature-insensitive refractive index sensor based on

an optical fiber extrinsic Fabry–Perot interferometer

processed by a femtosecond laser

Pengfei Liu (刘鹏飞), Lan Jiang (姜 澜), Sumei Wang (王素梅)*,

Zhitao Cao (曹志涛), and Peng Wang (王 鹏)

Laser Micro/Nano Fabrication Laboratory, School of Mechanical Engineering,

Beijing Institute of Technology, Beijing 100081, China

*Corresponding author: wangsumei@bit.edu.cn

Received October 12, 2015; accepted November 26, 2015; posted online January 27, 2016

An optical fiber extrinsic Fabry–Perot interferometer (EFPI) is designed and fabricated for refractive index (RI)

sensing. To test the RI of liquid, the following two different methods are adopted: the wavelength tracking

method and the Fourier-transform white-light interferometry (FTWLI). The sensitivities of sensors with cavity

lengths of 288.1 and 358.5 μm are 702.312 nm/RIU and 396.362 μm/RIU, respectively, by the two methods. Our

work provides a new kind of RI sensor with the advantages of high sensitivity, mechanical robustness, and low

cross sensitivity to temperature. Also, we provide a new method to deal with gold film with a femtosecond laser.

OCIS codes: 060.2280, 060.2370.

doi: 10.3788/COL201614.020602.

In recent years, many fiber sensors based on Fabry–Perot

interferometers (FPIs) have been fabricated and used to

measure different parameters such as refractive index

(RI), humidity, temperature, and so on

[1–6]

. For example,

an all-in-fiber prototype optofluidic device was fabricated

by femtosecond laser irradiation and subsequent selective

chemical wet etching. The optical Fabry–Perot cavity was

formed for measurement of the RI of the filling liquids

[1]

.

A fiber extrinsic FPI (EFPI) for humidity measurement

based on a polyvinyl alcohol (PVA) film is proposed and

experimentally demonstrated

[2]

. Also, a small air gap

between the end face of a single-mode fiber and an ultrathin

graphene was used as an EFPI cavity for temperature

measurement

[3]

. Furthermore, the EFPI shown in Ref. [4]

was used for pressure sensing with a sensitivity of

10.18 nm/kPa.

For RI sensing, a lot of different kinds of fiber sensors

based on different principles have been developed, such as

a Michelson interferometer (MI)

[7,8]

, long period fiber gra-

tings (LPFG)

[9,10]

, and a Mach–Zehnder interferometer

(MZI)

[11,12]

. As for the FPI, some sandwich-structured

Fabry–Perot sensors that use a short section of a different

type of fiber, instead of the air cavity, exhibit superior per-

formance

[13]

. However, rather poor optical performance

was shown because of the small index difference between

the two spliced fibers

[5]

. The FPI mentioned in Ref. [6]

shows a high sensitivity in RI sensing, but it is difficult

to make sure that the two reflective faces are fabricated

by the femtosecond laser vertical to the axial direction

of fiber because of trapezoid groove formed in laser fabri-

cation. What is more, too much ablation deep into the

fiber will cause fragility problems.

In this Letter, we propose a new EFPI-based RI sensor

that is assembled by a silica glass capillary. Two different

methods are adopted to test the RI of the liquid.

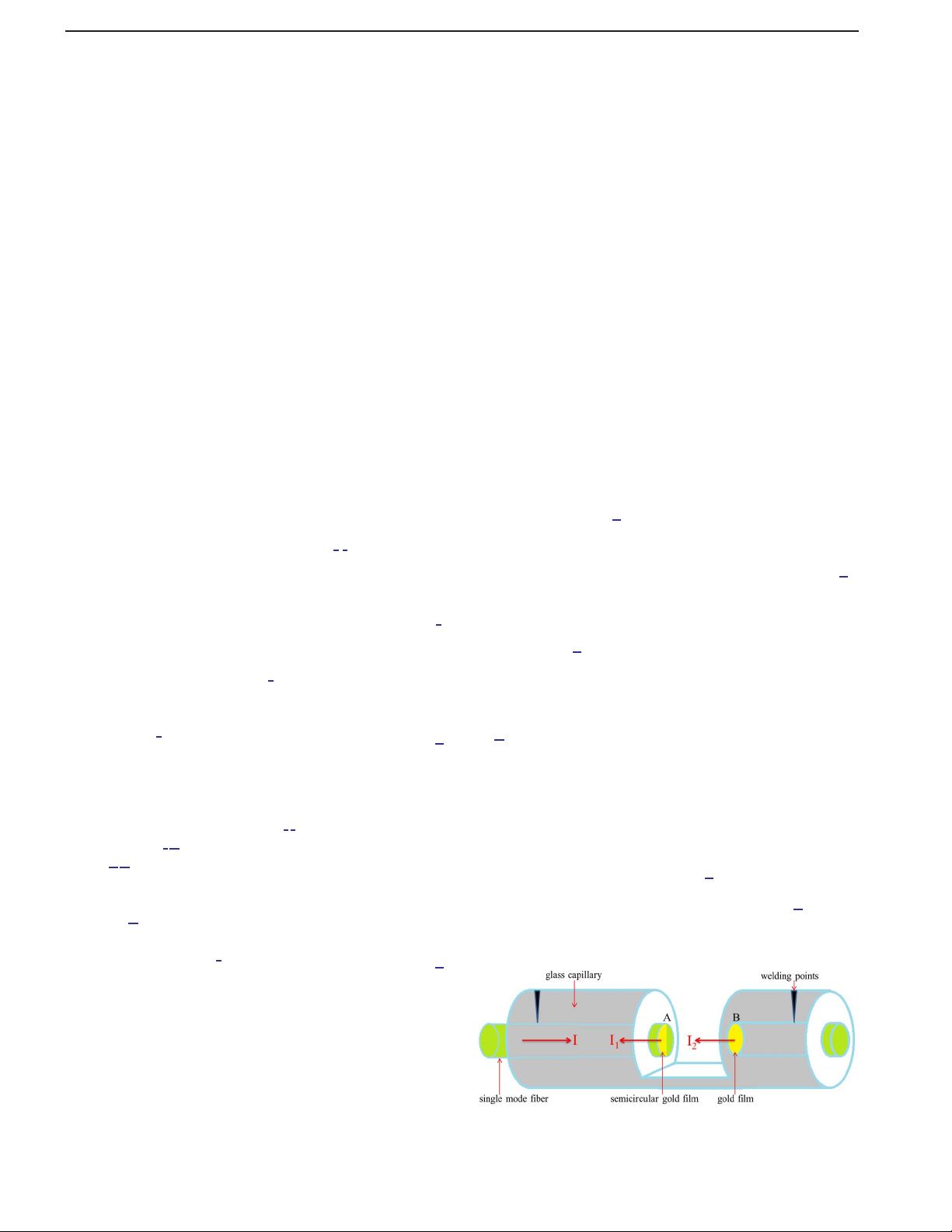

The proposed EFPI consists of two fiber end faces (A

and B shown in Fig.

1) both coated with gold film by vac-

uum sputtering for about 80 s. Then, one of them is

scanned by a femtosecond laser to remove half of its gold

film, to form a semicircular gold film (A shown in Fig.

1).

After that, the two fiber ends are assembled by a silica

glass capillary with the outer diameter of 1.8 mm and

inner diameter of 0.127 mm. The schematic diagram is

shown in Fig.

1.

It is worth mentioning that the capillary has been

ground by a diamond wheel to a depth about 1 mm on

its side face ahead of time in order to expose its capillary

channel so that we could let in different liquids to test the

RI

[14]

. After the two fibers are inserted into the silica glass

capillary channel, CO

2

laser welding is adopted to bond

the fibers and the capillary. For two different RI sensing

experiments, we have prepared two FPIs with different

cavity lengths, 288.1 and 358.5 μm, which mean two differ-

ent distances between the two fiber end faces. The photos

of the two fiber end faces and the whole assembly under

the microscope are shown in Fig.

2.

When used to test the RI of a liquid, the proposed EFPI

is connected to an interrogator (made by Jiang

[15]

) with a

monitor displaying the optical spectrum and the other

Fig. 1. Schematic diagram of the proposed EFPI.

COL 14(2), 020602(2016) CHINESE OPTICS LETTERS February 10, 2016

1671-7694/2016/020602(5) 020602-1 © 2016 Chinese Optics Letters