没有合适的资源?快使用搜索试试~ 我知道了~

首页西门子伺服电机样本大全:ISO认证、产品系列概览

西门子伺服电机样本大全:ISO认证、产品系列概览

西门子伺服电机样本提供了全面的产品和服务概述,旨在满足工业自动化领域的高精度和高效需求。这些电机包括同步和异步伺服电机,专为西门子SIMOVERT MASTER DRIVES系列设计,适用于广泛的功率范围,从0.55千瓦(0.74马力)到250千瓦(335马力)。样本中特别提到了DA65.3、DA65.10、DA65.11、DA65.4以及PM10/SIMOTION等型号,每种电机都配备有先进的运动控制功能,如矢量控制,以实现精确的扭矩控制和快速响应。

西门子在质量上坚持高标准,其产品和服务均遵循DIN EN ISO 9001(质量管理体系认证编号001258 QM)和DIN EN ISO 14001(环境管理体系认证编号081342 UM)国际标准,确保了产品的可靠性和环保性。样本中的订单号(如E86060-K5165-A101-A3和E86060-K4910-A101-A4)为用户提供了购买和定制电机的依据。

此外,样本还包含了其他相关组件如SIMODRIVE 611通用驱动器和CA01自动化元件,以及用于在线查找更多信息的网址www.siemens.com/automation/mall。值得注意的是,所有提及的产品名称可能是西门子公司或其供应商的商标,未经授权的第三方使用可能会侵犯商标权。

该样本不仅提供电机本身的技术规格,还可能包含安装指南、接线图、维护手册等技术文档,以帮助用户顺利集成和操作西门子伺服电机系统。整体而言,这份样本是工程师、技术员和系统集成商进行选择和设计西门子伺服电机解决方案的重要参考资料。

Siemens DA 65.3 · 2004

1/12

Servo Motors

Technical Definitions

Overview

1

■

Regulations, Standards and Specifications

These motors comply with the relevant standards and regula-

tions; see table below.

Many countries have completely harmonized their national reg-

ulations with the international IEC 60034-1 recommendation; as

a result, the coolant temperatures, temperature classes, and

temperature-rise limits in these national regulations are now the

same as in IEC 60034-1.

The following motors have the UL approval of “Underwriters

Laboratories Inc.

®

” as well as approval for Canadian standards

indicated by the URc symbol 1FK7, 1FT6 natural cooled, 1FW3,

1PH7 (without brake), 1PL6, 1PH4.

■

Most Common Degrees of Protection for AC Motors in Accordance with IEC 60034-5

Taking into account the operating and environmental conditions,

an appropriate degree of protection is selected to prevent the

following occurrences:

• Ingress of water, dust and foreign objects

• Contact with the rotating parts inside a motor

• Contact with energized parts

The degrees of protection for electrical machines are indicated

by a code composed of two letters, two numbers, and an addi-

tional letter, if required.

IP (International Protection)

These letters stand for the degree of protection against contact

and ingress of foreign objects and water

0 to 6

The first number stands for the degree of protection against con-

tact and ingress of foreign objects

0 to 8

The second number stands for the degree of protection against

ingress of water (not including oil insulation)

W, S and M

Additional letters stand for special types of protection

Title DIN/VDE EN IEC

General Specifications for Rotating Electrical Machines DIN VDE 0530 Part 1 EN 60034-1 IEC 60034-1

Terminal Markings and Direction of Rotation for Electrical Machines DIN VDE 0530 Part 8 EN 60034-8 IEC 60034-8

Types of Construction of Rotating Electrical Machines DIN VDE 0530 Part 7 EN 60034-7 IEC 60034-7

Methods of Cooling for Rotating Electrical Machines DIN VDE 0530 Part 6 EN 60034-6 IEC 60034-6

Degrees of Protection of Rotating Electrical Machines DIN VDE 0530 Part 5 EN 60034-5 IEC 60034-5

Vibration Severity of Rotating Electrical Machines DIN VDE 0530 Part 14 EN 60034-14 IEC 60034-14

Noise Limits of Rotating Electrical Machines DIN VDE 0530 Part 9 EN 60034-9 IEC 60034-9

Cylindrical Shaft Ends for Electrical Machines DIN 748 Part 3 – IEC 60072

Primarily, these motors are supplied with the following degrees of

protection:

Motor Degree

of

Protec-

tion

1st Number

Protection

against

Contact

Protection

against For-

eign Objects

2nd Number

Water Protection

Inter-

nally

cooled

IP23 Protected

against

finger

contact

Protected

against

medium-sized

foreign

objects

greater than

12 mm

(0.47 in) Ø

Protected against

spraying water

when tilted up to

60 °C (140 °F)

Surface

cooled

IP54 Fully

protected

against

contact

Protected

against

harmful dust

deposits

Splashing water from

all directions

IP55 Water jets from

all directions

IP64 Fully

protected

against

contact

Protected

against

dust

penetration

Splashing water from

all directions

IP65

1

) Water jets from

all directions

IP67

1

) Motor is protected

against effects of

immersion for

specific time and

pressure

IP68

1

) Motor is suited for

continuous submer-

sion under condi-

tions described by

the manufacturer

1) In accordance with DIN VDE 0530 Part 5 and EN 60034 Part 5, for

rotating electrical machines, there are only five degrees of protection

for the first number and eight degrees of protection for the second

number. However, IP6 is contained within DIN 40 050, which applies

for electrical equipment in general.

Siemens DA 65.3 · 2004

1/13

Servo Motors

Overview

Technical Definitions

1

■

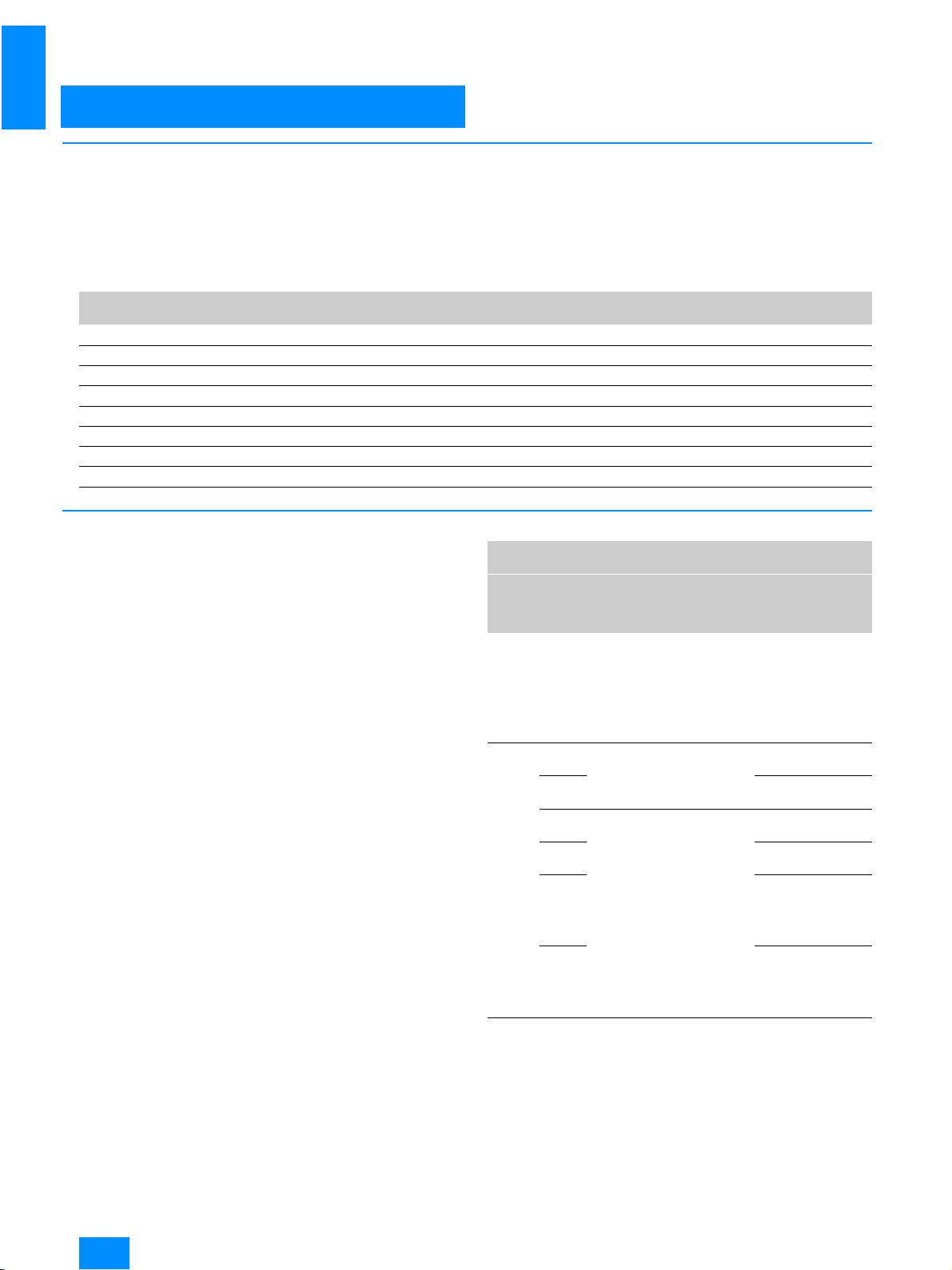

Radial Eccentricity Tolerance, Shaft and Flange Accuracy (Concentricity and Axial Eccentricity) in Accordance with IEC 60072

Radial eccentricity tolerance of the shaft to the housing axis

(with reference to the cylindrical shaft ends)

Concentricity and axial eccentricity tolerance of the flange

surface to the shaft axis (with reference to the centering diam-

eter of the mounting flange)

■

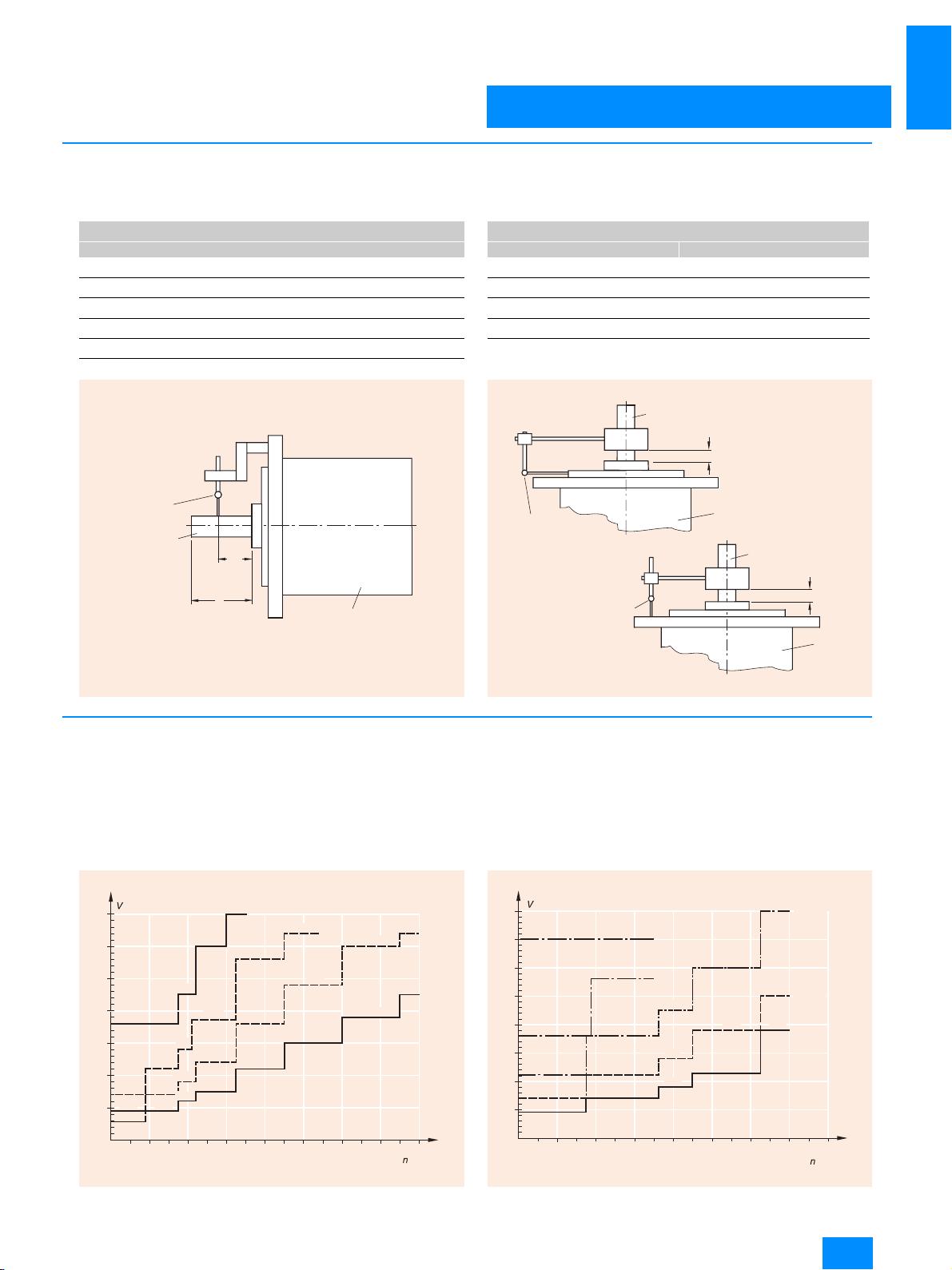

Vibration Severity Levels in Accordance with IEC 60034-14

The vibration severity is the quadratic mean (rms) value of the

vibration velocity (in a frequency range of 10 to 1000 Hz). The

vibration velocity is measured with electrical measuring equip-

ment in accordance with DIN 45 666.

The values indicated refer only to the motor. The system vibration

characteristics due to installation can cause these values to in-

crease.

Vibration Severity Level Limits for Shaft Heights of 28 to 132

Rotational speeds of 1800 rpm and 3600 rpm and their associ-

ated limits are specified in accordance with IEC 60034-14. Rota-

tional speeds of 4500 rpm and 6000 rpm and their associated

values have been specified by the motor manufacturer.

Vibration Severity Level Limits for Shaft Heights of 160 to 280

Shaft height Standard N Option R

mm (in) mm (in)

28, 36 0.035 (0.0014) 0.018 (0.0007)

48, 63, 71 0.04 (0.0016) 0.021 (0.0008)

80, 100, 132 0.05 (0.002) 0.025 (0.001)

160, 180, 225 0.06 (0.0023) 0.03 (0.0012)

280 0.07 (0.0028) 0.035 (0.0014)

L

L / 2

M o t o r

M o t o r s h a f t

D i a l g a u g e

T e s t : r a d i a l e c c e n t r i c i t y

G _ D A 6 5 _ E N _ 0 0 0 6 3

Shaft height Standard N Option R

mm (in) mm (in)

28, 36, 48 0.08 (0.0031) 0.04 (0.0016)

63, 71, 80, 100 0.1 (0.004) 0.05 (0.002)

132, 160, 180, 225 0.125 (0.0049) 0.063 (0.0025)

280 0.16 (0.0063) 0.08 (0.0031)

M o t o r s h a f t

M o t o r s h a f t

M o t o r

D i a l g a u g e

D i a l g a u g e

M o t o r

T e s t : a x i a l e c c e n t r i c i t y

T e s t : c o n c e n t r i c i t y

G _ D A 6 5 _ E N _ 0 0 0 6 4 b

1 0 m m

( 0 . 4 i n )

1 0 m m

( 0 . 4 i n )

1

2

3

2 0 0 0 4 0 0 0 6 0 0 0 8 0 0 0 1 0 0 0 0 1 2 0 0 0 1 4 0 0 0 1 6 0 0 0

[ m m / s ]

P e r m i s s i b l e v i b r a t i o n r a t e

1 . 8 5

3 . 0

3 . 2

3 . 5

[ r p m ]

e f

G _ D A 6 5 _ E N _ 0 0 0 6 5

2 . 2 5

3 . 2

2 . 4

1 . 8

2 . 2 5

3 . 0

2 . 8

0 . 4 5

0 . 7 5

1 . 1 2

1 . 5

1 . 8

1 . 1 8

0 . 7 1

0 . 4 5

0 . 7 1

0 . 5 6

0 . 8 9

1 . 4

1 . 8 7

1 . 1 2

0 . 2 8

S t a g e N

S t a g e R

S t a g e S

S t a g e S R

1

2

3

2 0 0 0 3 0 0 0 4 0 0 0 5 0 0 0 6 0 0 0 7 0 0 0 8 0 0 0

4

1 0 0 0

[ m m / s ]

S t a g e S R

S t a g e S

S t a g e R

P e r m i s s i b l e v i b r a t i o n r a t e

[ r p m ]

e f f

G _ D A 6 5 _ E N _ 0 0 0 6 6 a

0 . 4 5

0 . 7 1

1 . 1 8

3 . 0

1 . 4

1 . 1 2

1 . 1 2

2 . 2 5

1 . 8

0 . 8 9

1 . 8 7 1 . 8 7

2 . 5

4 . 0

1 . 8

2 . 8

3 . 5

0 . 7 1

S t a g e N

5 0 &

S t a g e R

5 0 &

Siemens DA 65.3 · 2004

1/14

Servo Motors

Technical Definitions

Overview

1

■

Balancing in Accordance with DIN ISO 8821

Requirements for the balancing process for attachment

parts, belt pulleys, in particular

The vibrational quality characteristics of motors with attached

belt pulleys are determined primarily by the balance of the at-

tachment part, as well as the balance quality of the motor.

If the motor and the attachment part are balanced separately

prior to assembly, the balancing process of the belt pulley must

be adapted to the balancing type of the motor. The following bal-

ancing types exist for motors 1PH4, 1PH7, and 1PL6:

• Half-key balancing

• Full-key balancing

• Keyless shaft end

For motors 1PH7 and 1PL6, the balancing type is coded in the

order designation. Half- and full-key balanced motors are identi-

fied by an “H” (half-key) or an “F” (full key) on the shaft end face.

Motors 1FK7 and 1FT6 with featherkey are always half-key bal-

anced.

In general motors with a keyless shaft are recommended for

systems with the most stringent vibrational quality requirements.

Belt pulleys with two opposite featherkey ways, but only one

featherkey in the shaft end, are recommended for full-key-bal-

anced motors.

■

Vibration Stress, Immitted Vibration Values

The following maximum permissible vibration stress limits at full

reliability performance apply only for the permanent-magnet

synchronous motors 1FK7, 1FT6, and 1FS6 with applied brake.

Vibration stress (in accordance with IEC 68-2-6):

• 1 g axial (20 Hz to 2 kHz)

• 5 g radial (20 Hz to 2 kHz).

For all asynchronous motors 1PH7, 1PH4, and 1PL6, the follow-

ing limits apply for (immitted) vibration values introduced exter-

nally to the motor.

■

Coolant (Air) Temperature and Installation Altitude

Operation (unrestricted) CT = –15

°C (+5 °F) to +40 °C (104 °F)

The rated output (rated torque) is applicable for continuous duty

(S1) operation in accordance with DIN EN 60034-1 at the rated

frequency, a coolant temperature (CT) of 40

°C (104 °F), and an

installation altitude of 1000 m (3281.5 ft) above sea level.

All motors are Thermal Class F motors and are utilized in accor-

dance with Thermal Class F. For all other conditions, the table on

the right must be used to determine the permissible output

(torque).

The coolant temperature and installation altitude are rounded to

5

°C (41 °F) and 500 m (1640.8 ft), respectively.

Note about surface temperature:

The surface of these motors can reach a temperatures of over

100

°C (212 °F).

Vibration

frequency

Vibration Values for Shaft Heights

100 to 160 180 to 280

<6.3 Hz Vibration displacement s 0.16 mm

(0.007 in)

0.25 mm

(0.010 in)

6.3 ... 63 Hz Vibration velocity V

rms

4.5 mm/s)

(0.18 in/s)

7.1 mm/s

(0.28 in/s)

>63 Hz Vibration acceleration a 2.55 m/s

2

(8.38 ft/s

2

)

4.0 m/s

2

(13.13 ft/s

2

)

Installation

Altitude above

Sea Level

Coolant Temperature CT in °C (°F)

m

(ft)

<30

(86)

30 – 40

(86–104)

45

(113)

50

(122)

1000

(3281.5)

1.07 1.00 0.96 0.92

1500

(4922.3)

1.04 0.97 0.93 0.89

2000

(6563)

1.00 0.94 0.90 0.86

2500

(8203.7)

0.96 0.90 0.86 0.83

3000

(9844.5)

0.92 0.86 0.82 0.79

3500

(11485.3)

0.88 0.82 0.79 0.75

4000

(13126)

0.82 0.77 0.74 0.71

Siemens DA 65.3 · 2004

1/15

Servo Motors

Overview

Technical Definitions

1

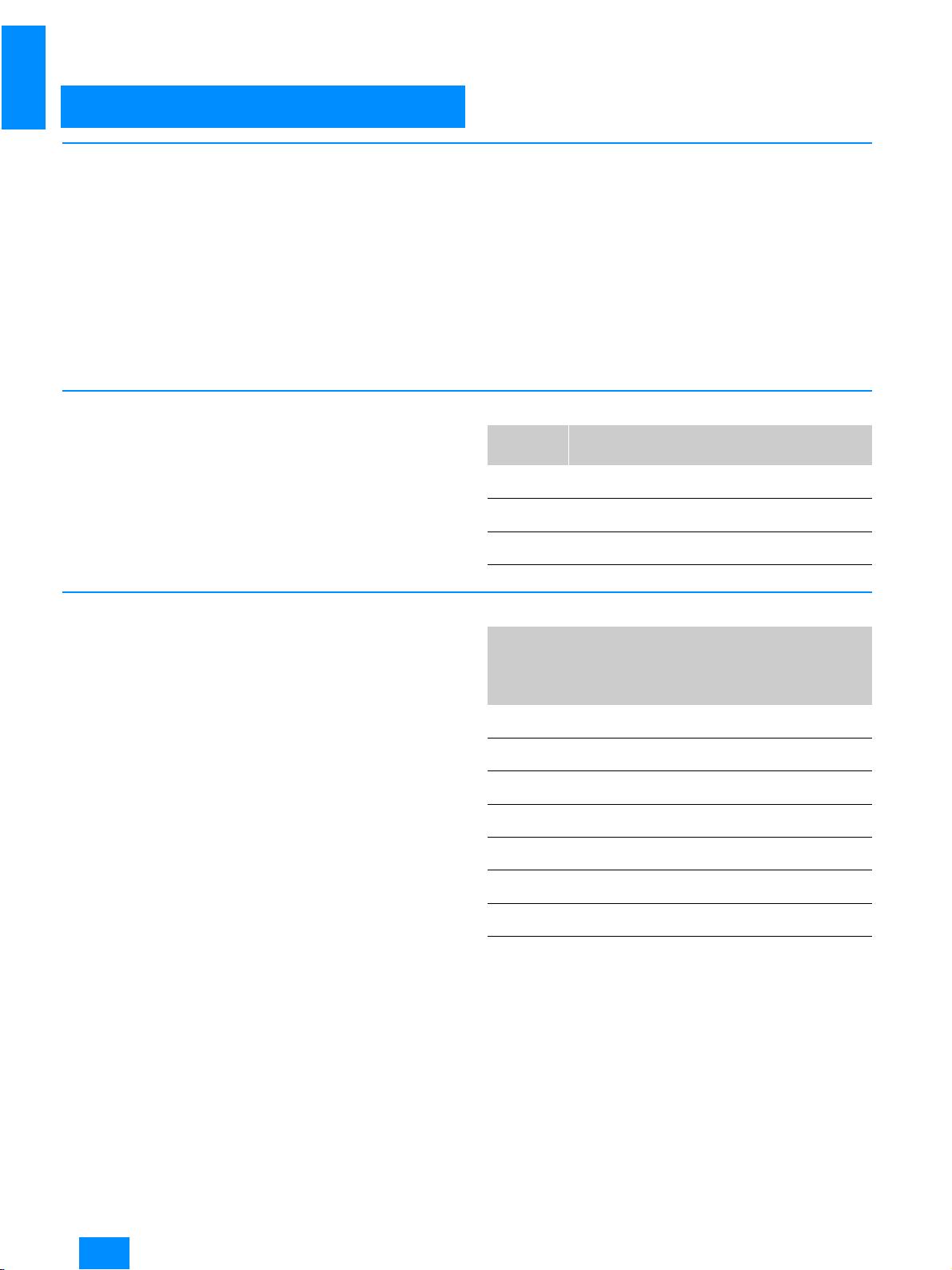

■

Operating Modes S1 and S6 in Accordance with EN 0530

■

Nameplates

P

t

P

t

t

DA65-5829

max

v

Duty cycle under constant

load condition of sufficient

duration to establish thermal

equilibrium

Designation: S1

Output specification

(torque)

S1: Continuous Running Duty

P

t

P

t

t

DA65-5830

t

v

B

t

L

t

S

max.

S6: Continuous Operation Periodic Duty

Duty cycle comprising a

sequence of identical duty

cycles, each of which con-

sists of a period of constant

load followed by an interval

at no load. There are no de-

energized intervals.

Designation:

i.e.: S6 - 40 %,

85 kW (114 HP).

t

t

tt

t

r

B

BL

s

=

+

=, min10

3 ~ Motor

1FK7060-5AF71-1EH0

M

o

6,0 Nm

EN60034

Brake EBD 0,8B / 24 V -- / 15 W

Made in Germany

Encoder F02

Rev. No. 000

No. YF PN18 4583 01 001

M

n

4,7 Nm

I

o

4,5 A

I

n

3,7 A

n

N

3000 /min.

n

max.

6600 /min.

Th.CI.F

U

in

253 V

IP 64

C

C

C

DA65-6038

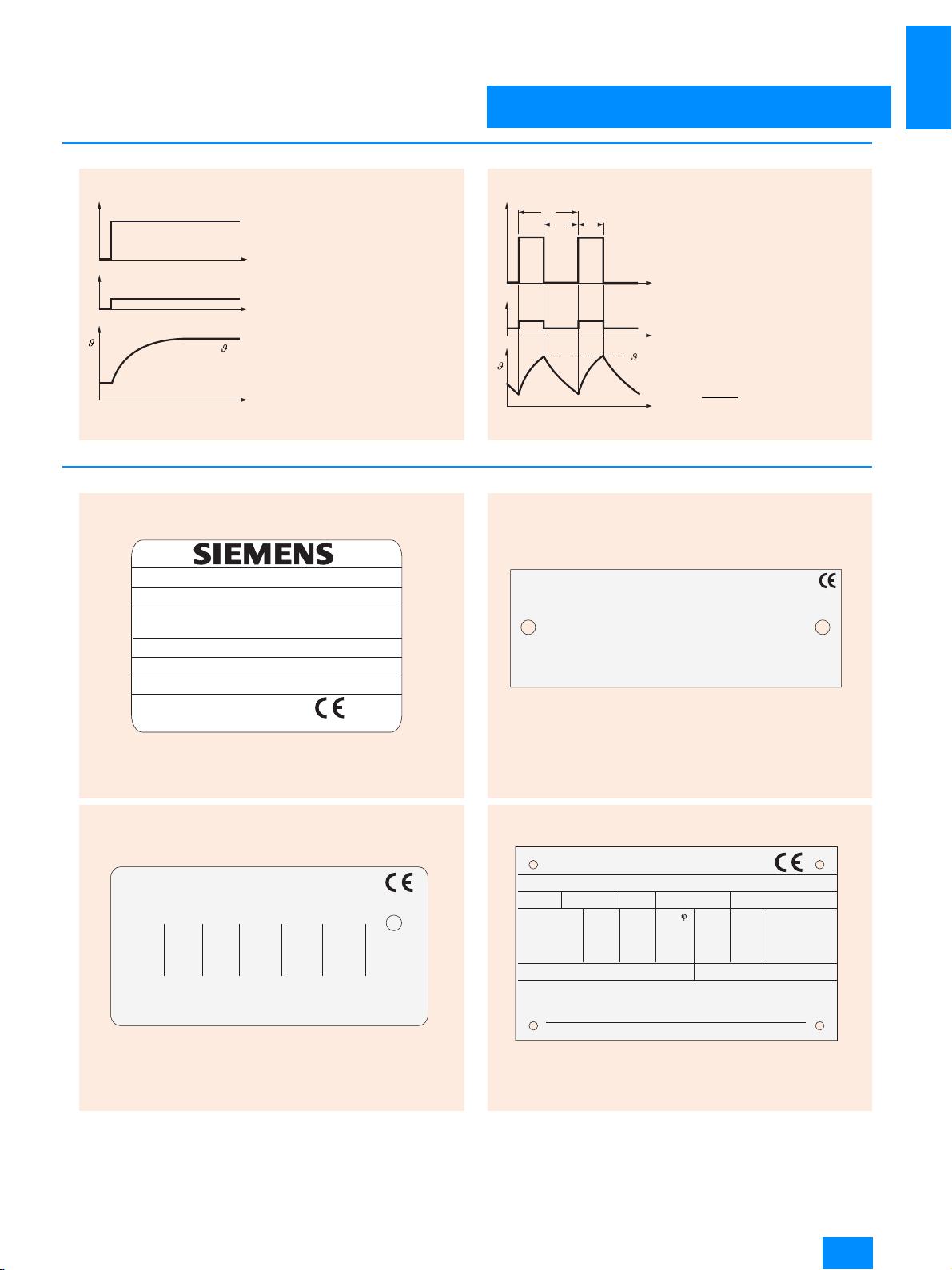

Example from the 1FK7 Series, Shaft Height 28 to 100 (Adhesive Plate)

Example from the 1PH7 Series, Shaft Height 100 to 160 (Adhesive Plate)

DA65-5837

3 ~ Mot

. 1PH7137 - 2NG00 - 0BA0 Nr.YF L994 0025 01 001

IM B3 IP 55/54 Th.CI.F

VA

kW

cos

1/min

EN 60034

TEMP - SENSOR KTY 84 - 130 ENCODER D01 2048 S/R

350 Y

398 Y

450 Y

Made in Germany

Hz

60,00

56,00

52,00

28,00

29,00

30,00

0,88

0,87

0,84

68,0

77,8

89,4

2000

2300

2650

S1

S1

S1

H

max. 8000 /min

CODE-NR.: 412

C

C

C

C

CC

3 ~ Brushless Servomotor

1FT6084-1AF71-3EG1

No.YF P118 9979 01 001 EN 60034

M

0

= 16,6/20,0 Nm I

0

= 11,3/14,0 A 60/100K

ABSOLUTE-ENCODER F02 2048 S/R KTY 84

M

N

= 14,0 Nm n

N

= 3000 /min U

IN

= 270 VY

IMB5 IP 65 Th.CL.F n

max

= 4700 /min

DA65-6041

Made in Germany

Example from the 1FT6 Series (Metal Plate)

C

C

C

No N- 1102033010001 / 2000

Th.CI. F

3 ~ Mot

. 1PL6228-4HF00-0AA0

IM B3

IP 23

Gew./WT 870 kg

VA

kW

1/min

345 Y

400 Y

460 Y

Hz

476

473

452

230

265

288

0.86

0.86

0.85

51

59

67

1500

1750

2000

EN60034-1 IEC 34-1 max 4500 1/min

MADE IN GERMANY

ENCODER H01 1024 S / R

KTY84

DA65-6033

cos

Example from the 1PL6 Series, Shaft Height 180 to 280 (Metal Plate)

Siemens DA 65.3 · 2004

1/16

Servo Motors

Technical Definitions

Overview

1

■

Rated Torque

The torque supplied on the shaft is indicated in Nm (lb

-in or

lb

-ft) in the technical selection table.

P

rated

Rated output in kW

n

rated

Rated speed in rpm

M

rated

Rated torque in Nm

P

rated

Rated output in HP

n

rated

Rated speed in rpm

M

rated

Rated torque in lb

-ft

■

DURIGNIT IR2000 Insulation

The DURIGNIT

®

IR 2000 insulation system consists of high-qual-

ity enameled wires and insulating sheeting in conjunction with

solvent-free resin impregnation.

It ensures that these motors will have a high level of mechanical

and electric strength as well as a high service value and a long

service life.

This insulation protects the winding to a large degree from the in-

fluence of harmful gases, fumes, dust, oil, and high humidity and

withstands normal vibration stresses.

The motor insulation is tropicalized, i.

e., suitable for air humidity

levels of up to 100

%.

All motors have Thermal Class F insulation.

The utilization of these motors corresponds to a Thermal Class F

rated output/torque.

■

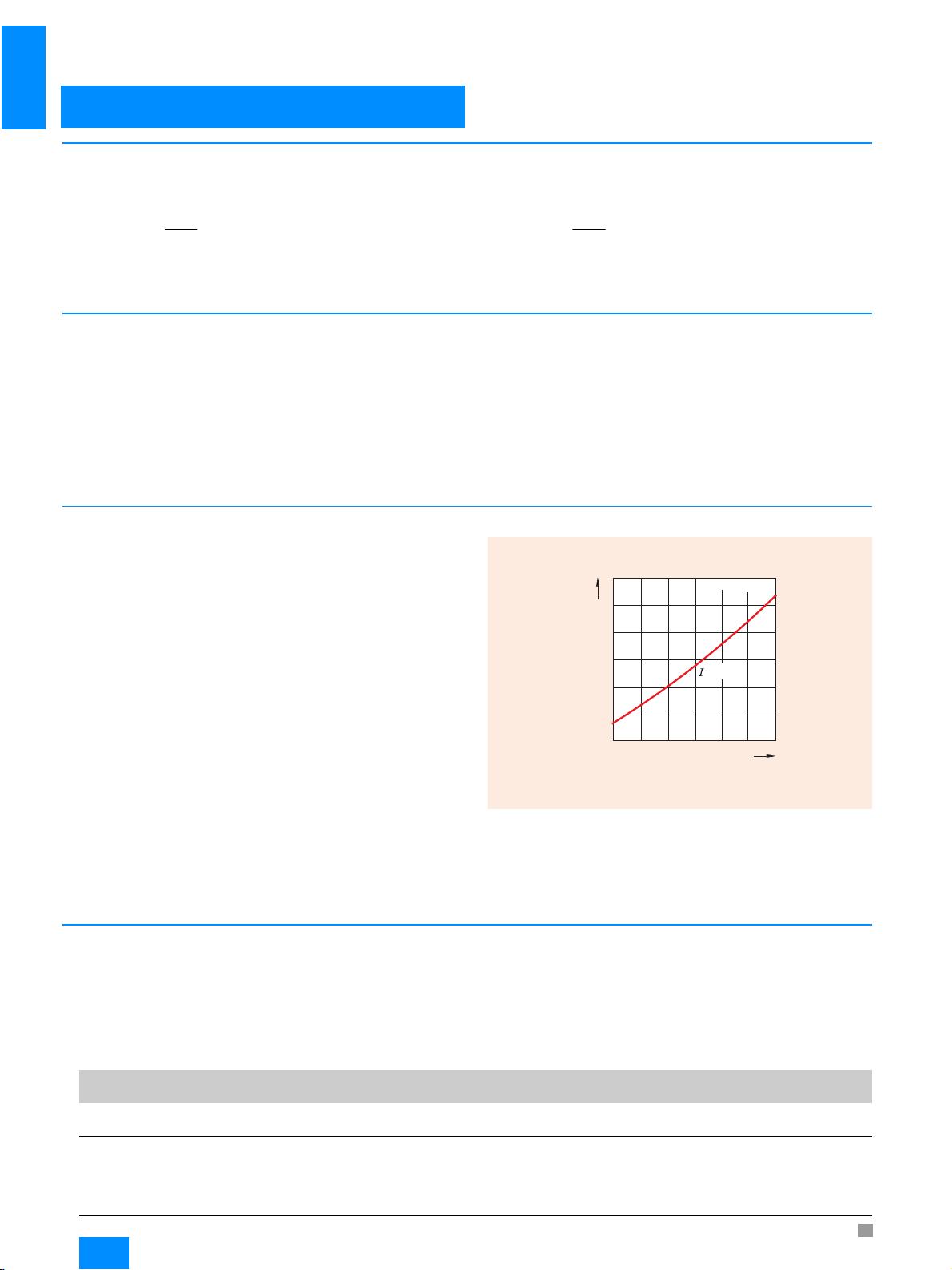

Motor Protection

The KTY 84-130 temperature sensor is used to measure the mo-

tor temperature for motor operation on the converter.

This sensor is a semiconductor that changes resistance accord-

ing to a defined curve in relationship to the temperature.

Siemens converters measure the motor temperature by means

of the temperature sensor resistance.

Their parameters can be set for specific warning and shutdown

temperatures.

The KTY 84-130 temperature sensor is built into the winding

overhang of the motor like a PTC thermistor.

The standard converter for this analysis is the

SIMOVERT MASTERDRIVES.

If the motors are operated on converters that do not have KTY 84

analysis, the temperature can be measured with the 3RS10 tem-

perature monitoring relay. For detailed information, see Catalog

LV 10.

Example units:

• Control supply voltage: 24 V AC/DC

Order no. 3RS1040-1GD50

• Control supply voltage: 24

– 240 V AC/DC

Order no. 3RS1040-1GW50

■

Paint Finish

The following finishes are available for these motors:

• Unpainted

(coated with impregnating resin) e.g. 1FK7 or 1PH7

(shaft height up to 160)

•Primed

(for corrosion control) e.g. 1PH7, 1PL6 (shaft height 180 and

higher)

• Standard finish

(e.g. RAL 7016) e.g. 1PH4, 1PH7, 1PL6, 1FK7, 1FS6

• Special finish

(e.g. RAL 7016) e.g. 1FT6, 1PH7, 1PL6

All motors can be painted over with commercially available

paint (up to 2 additional coats).

rated rated

rated

9550

MP

n

¸

rated rated

rated

5250

MP

n

¸

3 0 02 0 01 0 00

0

1

2

3

k

9

° C

G _ D A 6 5 _ E N _ 0 0 1 8 2

= 2 m A

4

6

U

( 3 2 ) ( 2 1 2 ) ( ° F ) ( 3 9 2 ) ( 5 7 2 )

D

Type Paint finish Suitability for Climate Group

in Accordance with DIN IEC 60721, Part 2 – 1

Standard finish Moderate (expanded)

For indoor and outdoor installation

Short-term:

Permanent:

Up to 120 °C (248 °F)

Up to 100 °C (212 °F)

Special finish Worldwide (expanded)

For outdoor installation

Short-term:

Permanent:

Up to 140 °C (284 °F)

Up to 120 °C (248 °F)

Also: Corrosive atmospheres of up to 1% acid or base

concentration or in sheltered, permanently damp

areas

剩余224页未读,继续阅读

226 浏览量

119 浏览量

2632 浏览量

435 浏览量

lsgs01

- 粉丝: 0

- 资源: 1

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功