MP2975 –DUAL LOOP DIGITAL PWM CONTROLLER FOR VR13.HC/AVSBUS

PRELIMINARY SPECIFICATIONS SUBJECT TO CHANGE

MP2975 Rev. 0.4 www.MonolithicPower.com 20

1/2/2019 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

Preliminary Specifications Subject to Change © 2019 MPS. All Rights Reserved.

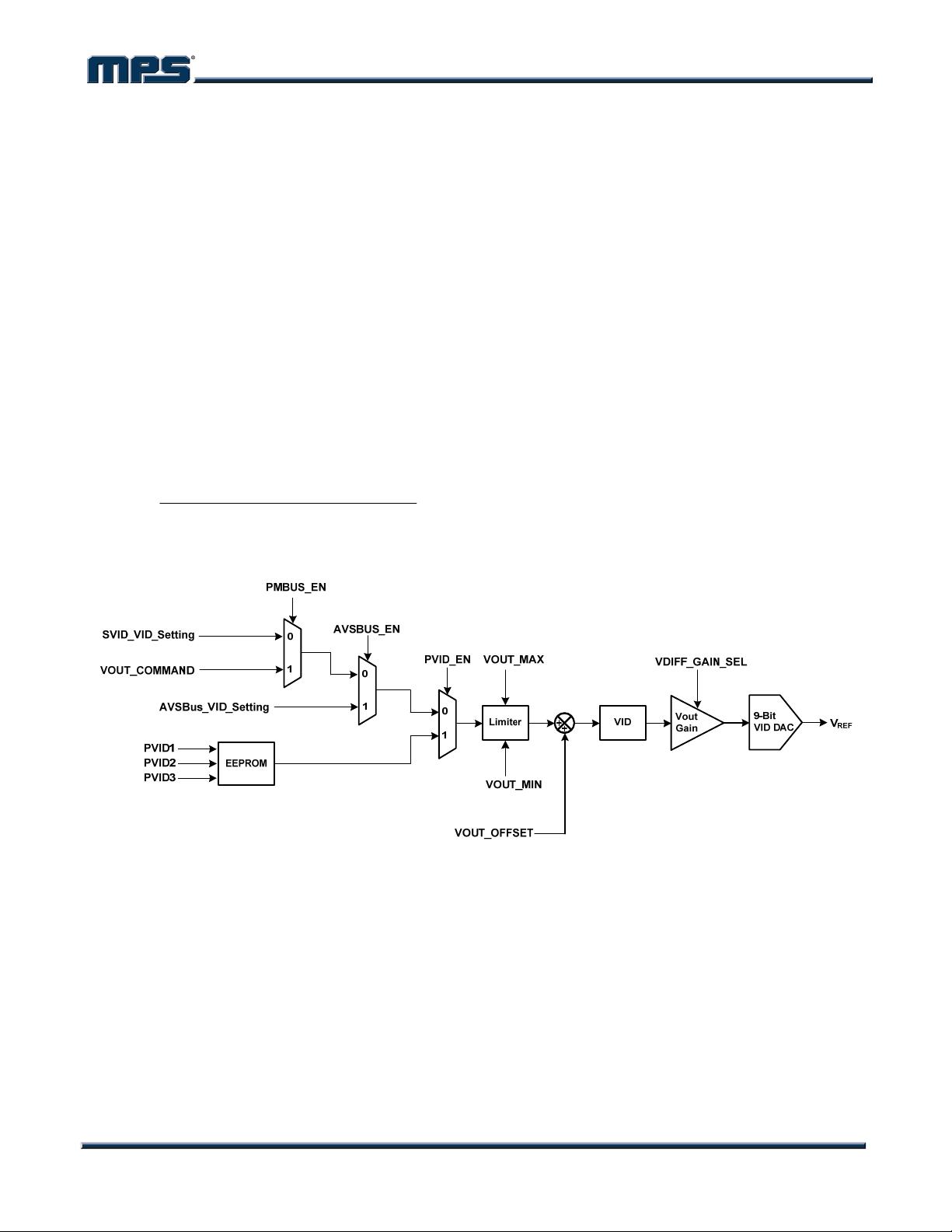

Dynamic Voltage Identification (DVID)

The MP2975 supports dynamical output voltage

transition by changing VID code with the PMBus

interface, AVSBUS interface, SVID interface, or

PVID pins toggling.

At the PMBus override control mode and PVID

control mode, the DVID slew rate is set to "Vout

transition slew rate" determined by Equation (6).

At the SVID control mode, the DVID slew rate is

determined by the SetVID command. The slew

rate of SetVID_Fast command is shown as

Equation (5); the slew rate of SetVID_Slow

command is shown in Table 2; the slew rate of

SetVID_Decay command can be set to "slow

slew rate" or free mode in which all PWMs turn to

tri-state and the Vout slew rate is determined by

the C

OUT

value and the load current. Refer to bit[9]

of register MFR_VR_CONFIG1 (68h) for detail.

At the AVSBUS control mode, the DVID slew rate

is determined by the Vout Transition Rate Write

command which is integer with 1LSB = 1mV/µs.

In one Vout Transition Rate command, the rise

slew rate is sent first, followed by the fall slew

rate. The initial rise and fall slew rate is

determined by VOUT_TRANSITION_RATE (27h)

as shown in Equation (7).

100 mV / s

AVS _ SR _INI

VOUT _ TRANS _ CNT

(7)

Where, VOUT_TRANS_CNT is the decimal value

in VOUT_TRANSITION_RATE (27h), bit [8:0],

which ranges from 1~511.

During a VID transient, the MP2975 forces the

VR into full phase CCM mode regardless the

power state setting. For example, if the controller

is configured as 6-phase mode but it is running in

1-phase DCM due to auto phase shedding, a VID

transition command will lead the controller run

into 6-phase CCM immediately.

Over-Clocking

The MP2975 supports 2 types of over-clocking

mode.

1. Tracking Mode

In over-clocking Tracking Mode, the VR

controller adds an offset VID with PMBus

command VOUT_OFFSET (1Eh @ page2).

When the CPU changes VID, the VR

will

provide an output by summing the VID from

CPU SetVID command and VID offset from

VOUT_OFFSET. One exception is when VR

receives SetVID to 0V command from CPU;

the output voltage goes to 0 V and the VID

offset is in-effective.

VOUT_OFFSET (1Eh @ page2) provides -

128 ~ +127 VID steps offset setting. At the

5mV VID table, the max offset is 0.635V and

max Vout is to 2.155V. At the 10mV VID table,

the max offset is 1.27V and max Vout is to 3V.

Tracking mode is effective at SVID, PMBus,

PVID and AVSBus mode all. Write a non-zero

value in VOUT_OFFSET register will enable

over-clocking tracking mode. If VR is on-the-

fly while updating VOUT_OFFSET, the output

voltage will slew to new target immediately.

2. Fix Mode

Fixed voltage margining is used in extreme

over-clocking application where fixed voltage

can provide additional stability. In this mode,

a fixed voltage is commanded with PMBus

command VOUT_COMMAND (21h), and the

VR output voltage will be fixed at this voltage

in regardless of VID changing command from

CPU. When the CPU issues a SetVID

command, the VR will ACK the command,

and assert ALERT# immediately, but keep

the voltage commanded by

VOUT_COMMAND (21h), while the VR

output voltage stays at the fixed VID.

Fix mode is only available at SVID override

mode. To enable over-clocking Fixed Mode,

set MFR_VR_CONFIG1 (68h @ page0), bit

[0] = 1. At the 5mV VID table, the max Vout is

to 2.72V with the VID table extending; at the

10mV VID table, the max Vout is to 3V.

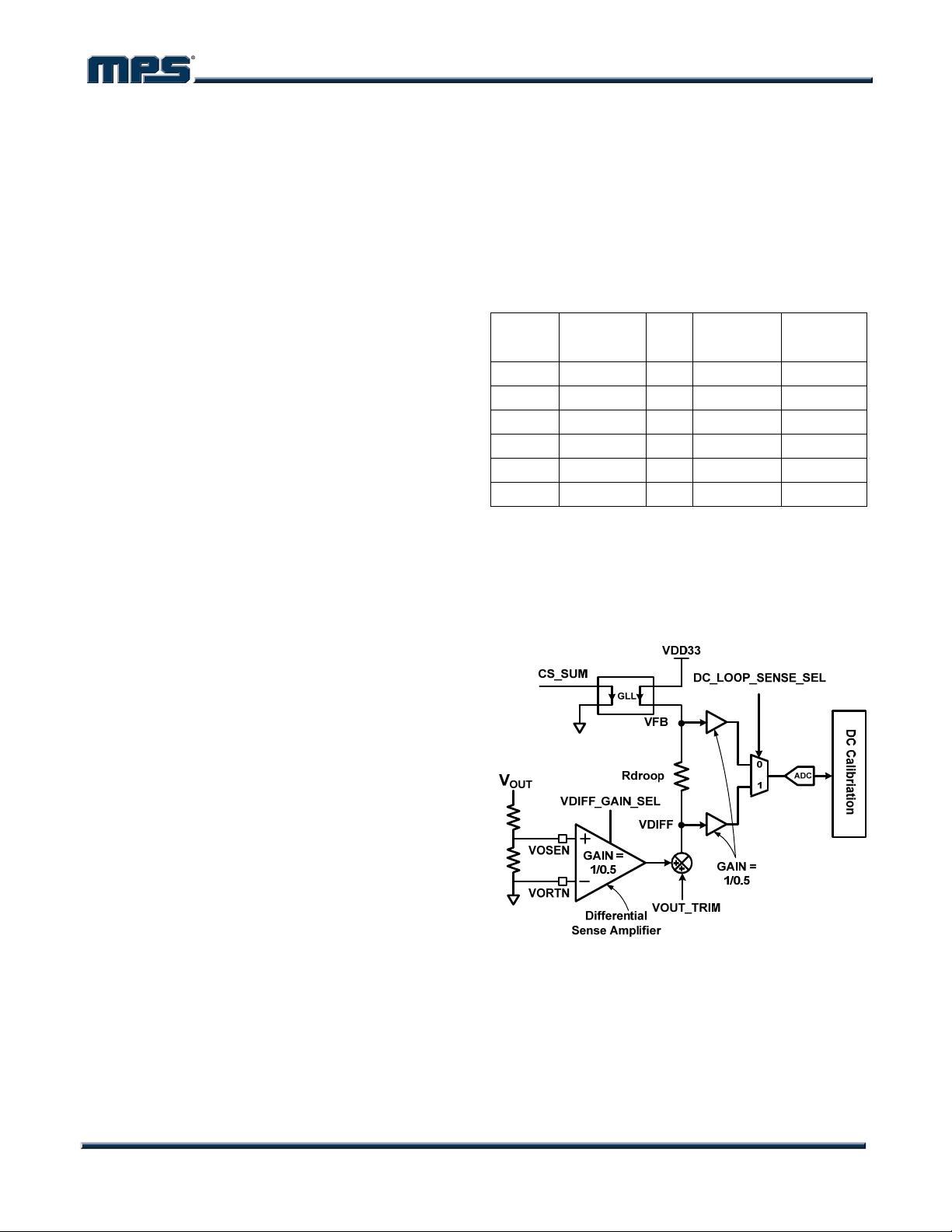

Inductor Current Sensing and Reporting

The MP2975 works with Intelli-Phase to realize

inductor current sensing (see Figure 5). The

cycle by cycle sensed inductor current is used for

multi-phase current balancing, thermal balancing

and per-phase current limitation.

When work with DrMOS which needs external

reference voltage for current sensing, the VDD18

of MP2975 can be used as the reference voltage.