PLCopen

for efficiency in automation

IEC 61131-3: a standard programming resource

IEC 61131-3 is the first real endeavor to standardize

programming languages for industrial automation. With its

worldwide support, it is independent of any single

company.

IEC 61131-3 is the third part of the IEC 61131 family.

This consists of:

• Part 1: General Overview

• Part 2 Hardware

• Part 3 Programming Languages

• Part 4 User Guidelines

• Part 5 Communication

• Part 7 Fuzzy Logic

• Part 8 Application Guidelines

There are many ways to look at part 3 of this standard. Just

to name a few:

• the result of the Task Force 3, Programming

Languages, within IEC TC65 SC65B

• the result of hard work by 7 international companies

adding tens of years of experience in the field of

industrial automation

• approx. 200 pages of text, with 60-something tables,

including features tables

• the specification of the syntax and semantics of a

unified suite of programming languages, including the

overall software model and a structuring language.

Another elegant view is by splitting the standard in two

parts (see figure 1):

1. Common Elements

2. Programming Languages

Let’s look more in detail to these parts:

Common Elements

Data Typing

Within the common elements, the data types are defined.

Data typing prevents errors in an early stage. It is used to

define the type of any parameter used. This avoids for

instance dividing a Date by an Integer.

Common datatypes are Boolean, Integer, Real and Byte

and Word, but also Date, Time_of_Day and String. Based

on these, one can define own personal data types, known

as derived data types. In this way one can define an analog

input channel as data type, and re-use this over an over

again.

Variables

Variables are only assigned to explicit hardware addresses

(e.g. input and outputs) in configurations, resources or

programs. In this way a high level of hardware

independency is created, supporting the reusability of the

software.

The scopes of the variables are normally limited to the

organization unit in which they are declared, e.g. local.

This means that their names can be reused in other parts

without any conflict, eliminating another source of errors,

e.g. the scratchpad. If the variables should have global

scope, they have to be declared as such (VAR_GLOBAL).

Parameters can be assigned an initial value at start up and

cold restart, in order to have the right setting.

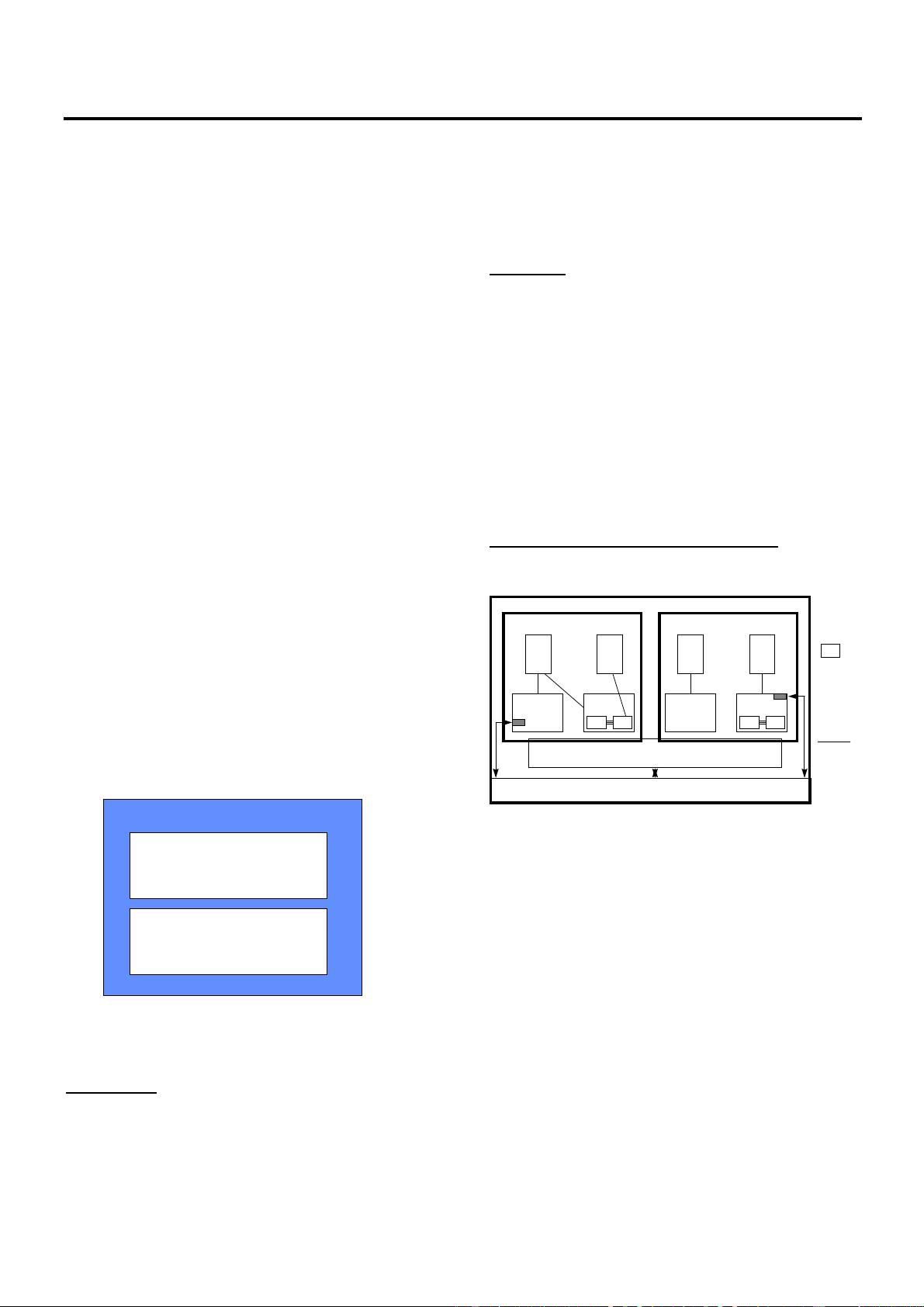

Configuration, Resources and Tasks

To understand these better, let us look at the software

model, as defined in the standard (see below).

Access path

Execution

control path

FB

Task

Program Program

FB FB

Task

Program

Task

Program

FB FB

Task

Resource Resource

Configuration

Function

Block

The IEC 61131-3 Standard

Common Elements

Programming Languages

At the highest level, the entire software required to solve a

particular control problem can be formulated as a

Configuration. A configuration is specific to a particular

type of control system, including the arrangement of the

hardware, i.c. processing resources, memory addresses for

I/O channels and system capabilities.

Within a configuration one can define one or more

Resources. One can look at a resource as a processing

facility that is able to execute IEC programs.

Within a resource, one or more Tasks can be defined.

Tasks control the execution of a set of programs and/or

function blocks. These can either be executed periodically

or upon the occurrence of a specified trigger, such as the

change of a variable.

Programs are built from a number of different software

elements written in any of the IEC defined languages.

Typically, a program consists of a network of Functions

and Function Blocks, which are able to exchange data.

Function and Function Blocks are the basic building

blocks, containing a datastructure and an algorithm.

Let’s compare this to a conventional PLC: this contains

one resource, running one task, controlling one program,

running in a closed loop. IEC 61131-3 adds much to this,