高级电气驱动:分析、建模与控制技术

"Advanced Electrical Drives - Analysis, Modeling, Control"

本书深入探讨了高级电气驱动技术,涵盖了电气驱动系统的核心组成部分及其控制策略。电气驱动在将电能转化为机械能的过程中起到关键作用,由电气机器(一种电-机械能转换器)、电力电子转换器(电-电转换器)和控制器/通信单元组成。这些组件共同工作,使得电气驱动被广泛应用于高速列车、电梯、自动扶梯、电动船舶、电动叉车和电动汽车等。

高级控制算法,尤其是数字实现的控制算法,能够实现高带宽的扭矩控制,从而实现精确的运动控制。这在机器人、拾放机器、工厂自动化设备等应用场景中尤为重要。例如,机器人驱动系统通过精密的控制算法,可以实现复杂而精准的动作,提高生产效率和质量。

作者包括Rik De Doncker、Duco W. J. Puller和André Veltman,分别来自 RWTH Aachen 大学、Zener Electric Pty Ltd. 和 Eindhoven 技术大学,他们在电气工程领域具有深厚的学术背景和实践经验。书中的内容可能包括但不限于:

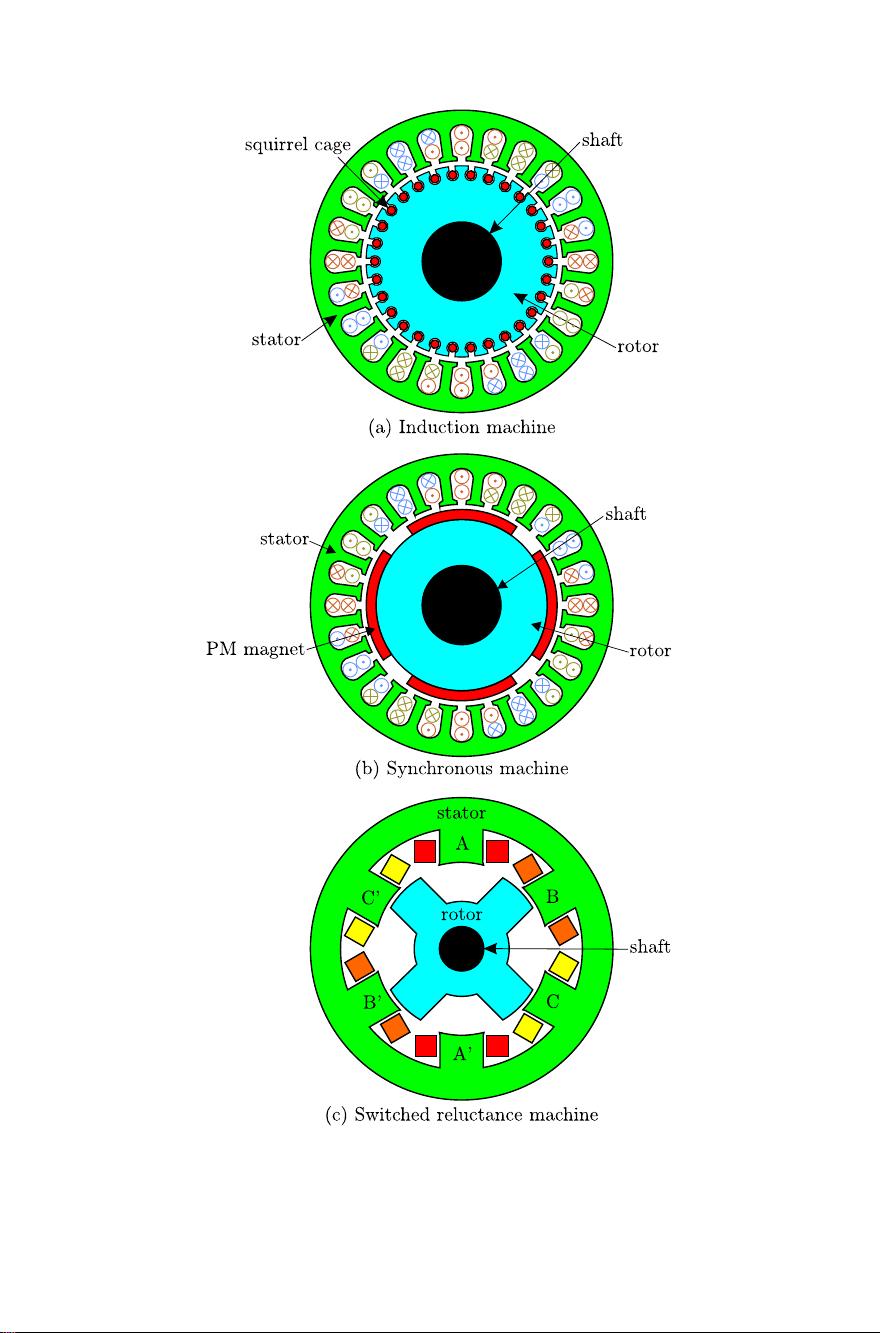

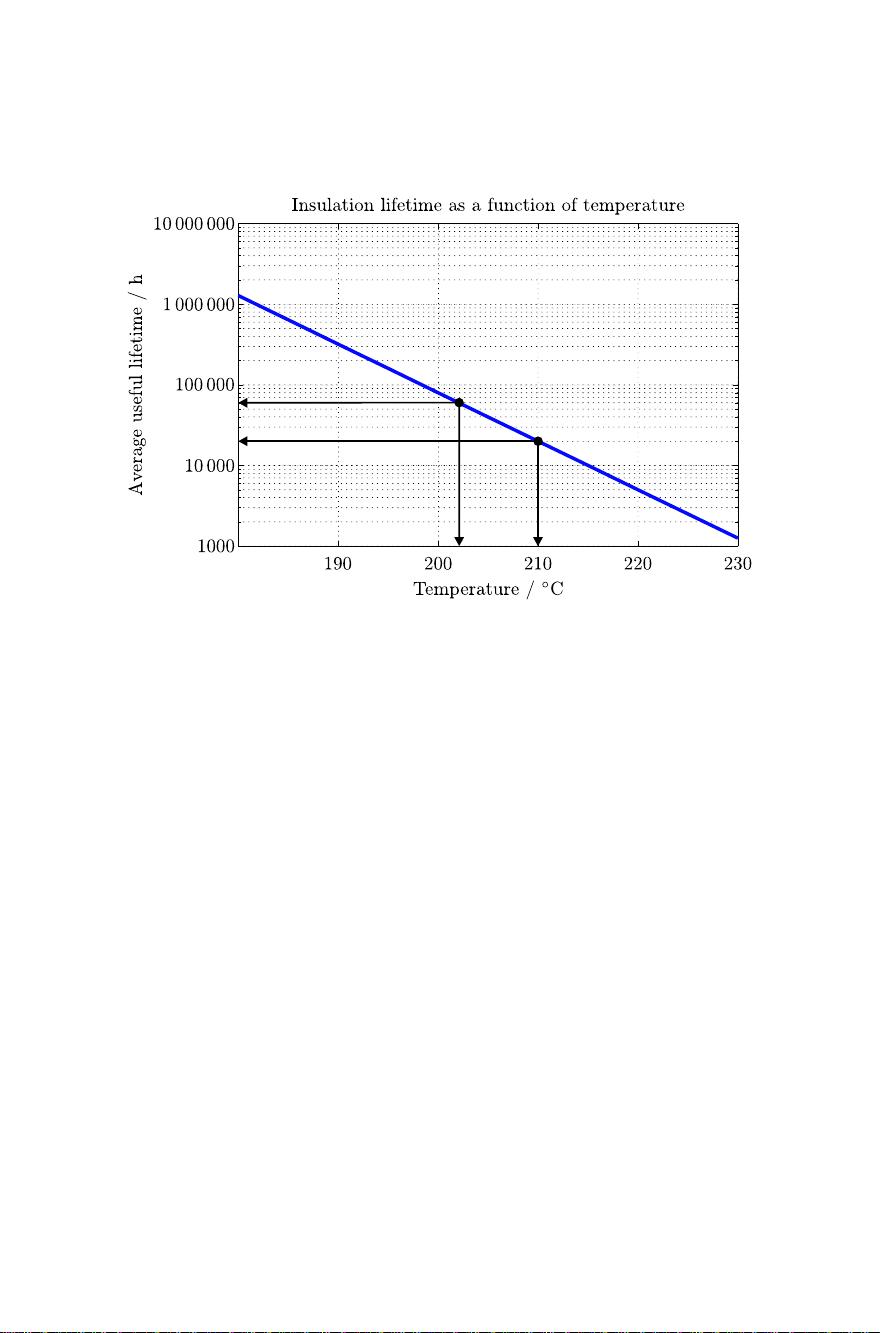

1. 电气机器分析:深入讨论电机的工作原理、性能特性,如感应电机、同步电机和直流电机等。

2. 功率电子转换器:涵盖逆变器、整流器和斩波器等,以及它们在电气驱动系统中的作用。

3. 控制策略:介绍各种先进控制算法,如矢量控制、直接转矩控制和自适应控制等,以及如何利用这些算法实现高效和精确的驱动控制。

4. 电气驱动系统的建模与仿真:讲解如何建立电气驱动系统的数学模型,以及如何通过仿真工具进行系统性能分析和优化。

5. 实际应用案例:通过具体的应用实例,展示电气驱动在不同领域的应用和挑战。

6. 数字化和通信技术:讨论现代电气驱动中嵌入式系统的应用,以及如何通过通信协议如CAN、EtherCAT等实现设备间的高效通信。

此外,书中还可能包含实验数据、设计指导和实用技巧,以帮助读者理解和应用这些理论知识。读者可以通过提供的额外材料网址获取更多补充资料,进一步增强学习体验。

《Advanced Electrical Drives - Analysis, Modeling, Control》是电气工程专业人士和学生深入了解电气驱动技术的重要参考书,它不仅提供了理论知识,还强调了实际应用和控制策略的实施。

456 浏览量

2024-10-26 上传

2024-10-26 上传

206 浏览量

122 浏览量

131 浏览量

109 浏览量

2021-04-17 上传

110 浏览量

TZG-Q

- 粉丝: 1

最新资源

- MATLAB实现ART与SART算法在医学CT重建中的应用

- S2SH整合版:快速搭建Struts2+Spring+Hibernate开发环境

- 托奇卡项目团队成员介绍

- 提升外链发布效率的SEO推广神器——搜易达网络推广大师v2.035

- C#打造简易记事本应用详细教程

- 探索虚拟现实地图VR的奥秘

- iOS模拟器屏幕截图新工具

- 深入解析JavaScript在生活应用开发中的运用

- STM32F10x函数库3.5中文版详解与应用

- 猎豹浏览器v6.0.114.13396 r1:安全防护与网购敢赔

- 掌握JS for循环输出的最简洁代码技巧

- Java入门教程:TranslationFileGenerator快速指南

- OpenDDS3.9源码解析及最新文档指南

- JavaScript提示框插件:鼠标滑过显示文章摘要

- MaskRCNN气球数据集:优质图像识别资源

- Laravel日志查看器:实现Apache多站点日志统一管理