Abstract—Nowadays, the increasing population increases the

consumption as well. Manufacturing systems are developing in

a fast pace to meet increasing demand of consumption. However,

very quick increase of production has surpassed the

development speed of currently existing control systems. In

manufacturing, since the quality is a very important issue as

well as the quantity, the operation of quality control systems

must be accelerated and must be accomplished by machines.

The idea of our study is based on this thinking. Especially defect

detection on widely used glass material that is extremely

difficult to accomplish by humans can be implemented in a

quick, accurate and stable way. In the presented method,

various defects like scratches, bubbles, cracks, corrosion on the

glass surface can be identified. Glass images obtained from a

homogenously illuminated medium are processed by wavelet

transform and obtained images from the wavelet transform are

denoised. Finally, Shannon threshold method is applied to the

images. From the obtained results, defects like scratches,

bubbles on the surface of the glass can be detected successfully.

Index Terms—Glass defect detection, texture analysis, image

processing, wavelet transform, machine vision.

I. INTRODUCTION

Nowadays, as a result of the rapidly expanding automation

systems, it is possible to increase number of manufactured

products in the proportion of supply and demand. In the

globalized world, very fast and effective productions in low

cost are aimed to be prepared for possible demands.

Depending on the arbitrary or compulsory requirements,

glass and glass products are preferred in many different

sectors such as packaging, mirror, kitchen industry,

insulation, heating. Among the manufactured glass products,

defected ones must be prevented to reach to the customer. To

ensure that, the manufactured products must be quality

controlled before leaving the factory. Quality control after

production is usually made by a machine network included to

the manufacturing automation to reduce defects.

Machine-based quality control systems are quite

advantageous compared to the human-based ones [1]-[3].

However, during the search for possible defects on the glass

by sensory technologies, the transparency and light

transmittance of the glass lead to extreme difficulties and

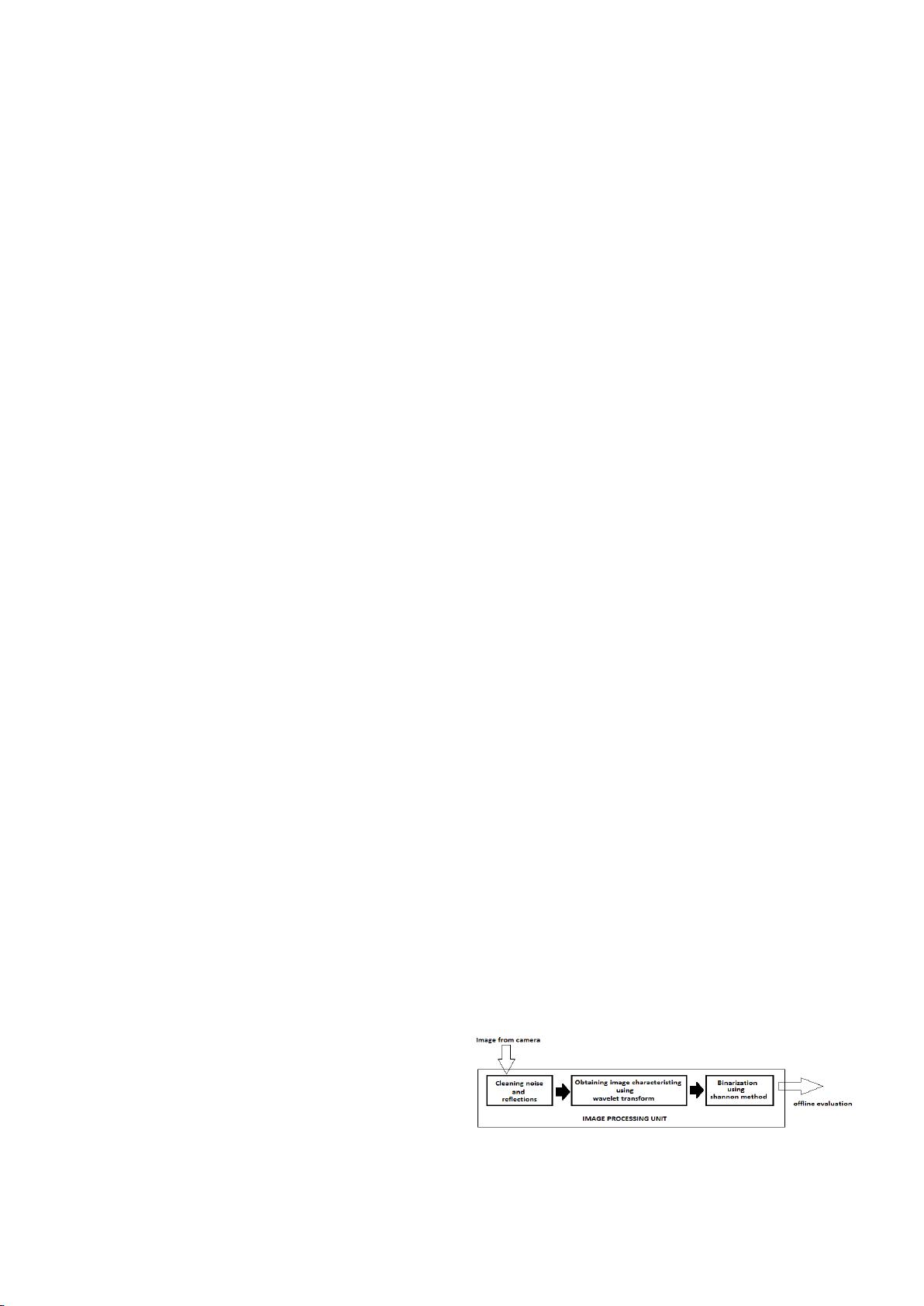

long delays to obtain desired results [4], [5]. For this, the

workload of camera which is image acquisition sensor should

be facilitated. One of the most important points is lighting

system. The lighting system must be designed taking into

account features of the camera. Lighting system should be

effectively illuminated the glass surface. Its main task is to

help image processing unit through illuminating

homogeneously whole glass surface. Other important issue is

position of the camera. It must be correctly calculate size of

defects on the glass surface. Thus, one or more cameras can

be used. If the angle increases between the glass surface and

the camera, calculations and estimating shape of defects

becomes more difficult.

Possible problems encountered on the glass during

production are defects like scratches, bubbles, cracks and

fractures. When these problems are detected during quality

control procedure, the products can be recycled and

reprocessed before they leave the factory. However, if the

defected glass reaches the consumer, besides increasing the

cost of recycling, the factory may be discredited. Therefore, it

is clear that the quality control must be made very carefully

and the product must be presented to the customer after this.

In this study, by implementing the quality control of glass in

an effective way, an effort is made to increase the quality of

the manufactured glass and avoid possible financial losses. A

number of different methods have been employed in glass

defect analysis and many studies for effective control are

present in literature. In order to detect the surface defects on

the glass, Markov random field [6] Otsu threshold method [7],

canny edge detection method [8], binary feature histogram

method [9], Fuzzy C Means clustering algorithm [10] have

been employed. In this study, the images taken from

homogenously illuminated medium are first preprocessed to

be denoised, processed via wavelet transform and

transformed into binary form by Shannon method. Shannon

Method is a common method to evaluate the edges [11]-[13].

Therefore, the defects over the glass can be detected in a

quick and accurate manner.

Wavelet analysis is becoming a popular tool for analyzing

localized variations of power within a time series. By

decomposing a time series into time–frequency space, one is

able to determine both the dominant modes of variability and

how those modes vary in time and wavelet transform has

been used for numerous studies such as image processing,

geophysics, ocean waves etc. [14]-[16].

In this study, the taken images have been evaluated using

wavelet transform for surface detection. Wavelet improves

Shannon entropy evaluates. Wavelet and Shannon entropy

were used together to determine the edges.

Fig. 1. Image processing unit.

Rest of this paper is organized as follow; Section II is

mentioned about system overview and definition of problem.

Section III is explained wavelet transform and using this

Glass Surface Defects Detection with Wavelet Transforms

Bayram Akdemir and Şaban Öztürk

170

International Journal of Materials, Mechanics and Manufacturing, Vol. 3, No. 3, August 2015

Manuscript received December 4, 2014; revised March 31, 2015. This

project (114E925) is supported by TUBİTAK.

The authors are with the Electrical and Electronics Engineering

Department, Engineering Faculty, University of Selcuk, Konya, Turkey

(e-mail: {bayakdemir, sabanozturk}@selcuk.edu.tr).

DOI: 10.7763/IJMMM.2015.V3.189