"基于PLC的烟气脱硫控制系统设计与监控"

版权申诉

3 浏览量

更新于2024-03-08

收藏 1.22MB DOCX 举报

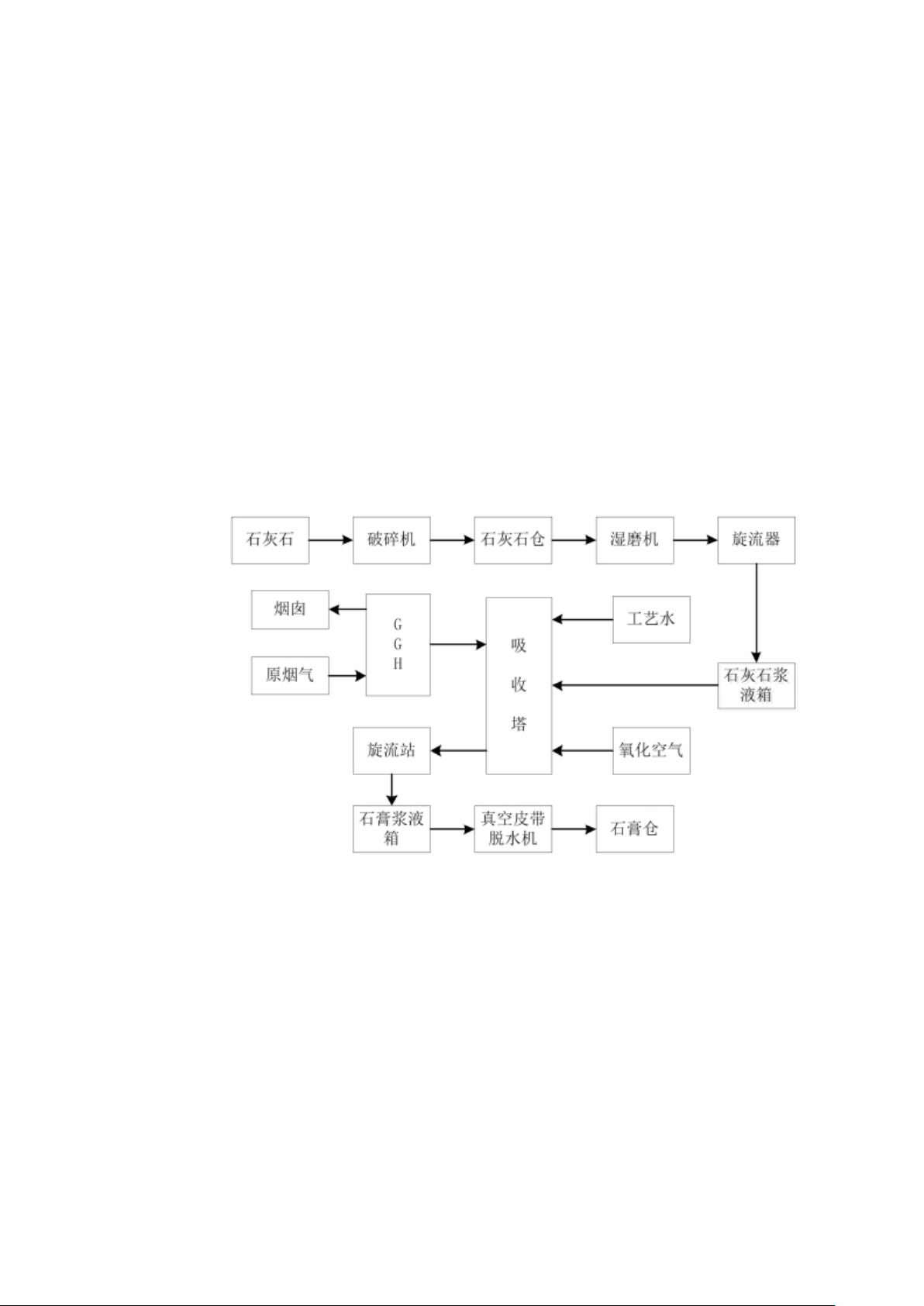

As the rapid development of Chinese industry continues, the issue of SO2 pollution has become a pressing environmental concern. To address this problem, various industries have adopted different desulfurization techniques to control SO2 emissions. In order to better desulfurize flue gas, this paper analyzes the limestone/gypsum flue gas desulfurization process and proposes a monitoring system design scheme based on SIEMENS PLC and HMI.

The system consists of four parts: limestone slurry preparation system, flue gas system, absorption system, and gypsum dewatering system. By utilizing the PID control algorithm built into SIEMENS PLC, the system achieves control over the pH value and concentration of the slurry in the absorption system, as well as the liquid level and concentration in the slurry preparation system. It also controls the opening angle of the booster fan in the flue gas system and the speed of the gypsum dewatering system, ultimately achieving comprehensive control over the flue gas desulfurization system to control SO2 emissions.

The results of debugging show that the system operates reliably, achieving control over the flue gas desulfurization system and meeting the expected effectiveness. In summary, the PLC-based monitoring system for FGD process effectively controls SO2 emissions and represents a significant step forward in addressing environmental concerns.

2022-07-12 上传

2020-08-14 上传

2023-06-10 上传

2023-12-24 上传

2023-02-24 上传

2023-05-30 上传

2023-05-31 上传

2023-04-04 上传

老帽爬新坡

- 粉丝: 87

- 资源: 2万+

最新资源

- Hadoop生态系统与MapReduce详解

- MDS系列三相整流桥模块技术规格与特性

- MFC编程:指针与句柄获取全面解析

- LM06:多模4G高速数据模块,支持GSM至TD-LTE

- 使用Gradle与Nexus构建私有仓库

- JAVA编程规范指南:命名规则与文件样式

- EMC VNX5500 存储系统日常维护指南

- 大数据驱动的互联网用户体验深度管理策略

- 改进型Booth算法:32位浮点阵列乘法器的高速设计与算法比较

- H3CNE网络认证重点知识整理

- Linux环境下MongoDB的详细安装教程

- 压缩文法的等价变换与多余规则删除

- BRMS入门指南:JBOSS安装与基础操作详解

- Win7环境下Android开发环境配置全攻略

- SHT10 C语言程序与LCD1602显示实例及精度校准

- 反垃圾邮件技术:现状与前景