NR 561, Sec 2

8

Bureau Veritas June 2021

SECTION 2 MATERIALS

Symbols

E : Young’s modulus of aluminium, equal to

70000 N/mm

2

ν : Poisson ratio of aluminium, equal to 0,33

R

m

: Tensile strength, in N/mm

2

, of the parent metal in

delivery condition, as specified

R

p0,2

: Proof stress (yield strength), in N/mm

2

, of the

parent metal in delivery condition, as specified

R

’

m

: Tensile strength, in N/mm

2

, of the parent metal

in as-welded condition, as defined in [2.1.3] or

[2.1.4]

R

’

p0,2

: Proof stress (yield strength), in N/mm

2

, of the

parent metal in as-welded condition, as defined

in Article [2].

1 General

1.1 Application

1.1.1 As a rule, the aluminium alloys used for the construc-

tion of aluminium ships are as follows:

• for rolled or extruded products:

- series 5000: aluminium-magnesium alloy

- series 6000: aluminium-magnesium-silicon alloy.

• for cast products:

- aluminium-magnesium alloy

- aluminium-silicon alloy

- aluminium-magnesium-silicon alloy.

In the early stages of the project, the shipyard is to submit to

the Society the characteristics of the materials they intend to

use for the construction of the hull and of the structures. In

particular, the temper of parent metal is to be indicated.

1.1.2 Manufacture, inspection and certification

The general requirements relevant to the manufacture,

inspection and certification of aluminium alloy products

entering in the hull construction are given in NR216 Rules

on Materials and Welding for the Classification of Marine

Units.

1.1.3 Aluminium alloy characteristics

The characteristics of aluminium alloy to be used in the

construction are to comply with the applicable require-

ments of NR216 Materials and Welding, Chapter 3,

Section 2.

Materials with different characteristics may be considered

provided their specification (manufacture, chemical com-

position, mechanical properties, welding, etc.) is submitted

to the Society for approval.

1.1.4 In the case of structures subjected to low service tem-

peratures or intended for other specific applications, the

alloys to be employed are to be agreed by the Society.

2 Aluminium structure

2.1 Influence of welding on mechanical

characteristics

2.1.1 Welding heat input lowers locally the mechanical

characteristics R

p0,2

and R

m

of aluminium alloys hardened

by work hardening (series 5000 other than condition O) or

by heat treatment (series 6000).

2.1.2 Consequently, where necessary, a drop in the

mechanical characteristics of welded structures, with

respect to those of the parent material, is to be considered

for the structure calculation.

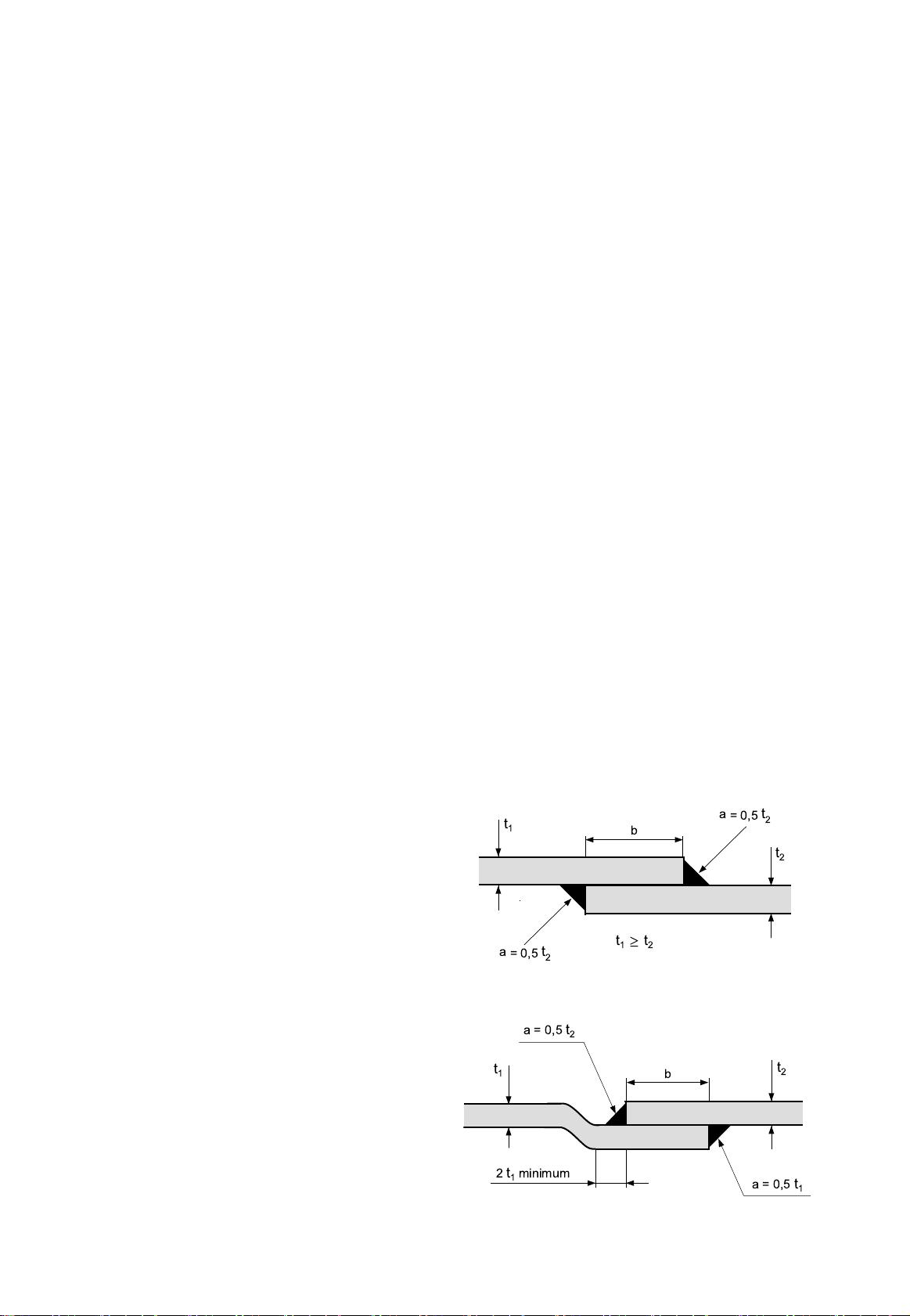

As a general rule, the heat affected zone (HAZ) is to be

taken extending over 25 mm on each side of the weld axis.

2.1.3 Aluminium alloys of series 5000 (rolled and

extruded)

Aluminium alloys of series 5000 in O condition (annealed)

are not subject to a drop in mechanical strength in the

welded areas.

Aluminium alloys of series 5000 other than condition O are

subject to a drop in mechanical strength in the welded

areas. The mechanical characteristics to be considered are

normally those of condition O.

Note 1: Higher mechanical characteristics may be taken into

account, provided they are duly justified.

2.1.4 Aluminium alloys of series 6000

Aluminium alloys of series 6000 are subject to a drop in

mechanical strength in the vicinity of the welded areas.

The mechanical characteristics to be considered in this

HAZ are normally indicated by the supplier.

When no information is provided by the supplier, the values

given in Tab 1 may be used.

Note 1: Higher mechanical characteristics may be taken into

account, provided they are duly justified.

2.1.5 Hardened aluminium alloys

For welded constructions in hardened aluminium alloys

(series 5000 other than condition O and series 6000),

higher characteristics than those in welded condition may

be considered, provided that welded connections are

located in areas where stress levels are acceptable for the

alloy considered in annealed or as-welded condition.