TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09) 18

www.trinamic.com

3.7 High Motor Current

When operating at a high motor current, the driver power dissipation due to MOSFET switch on-

resistance significantly heats up the driver. This power dissipation will heat up the PCB cooling

infrastructure also, if operated at an increased duty cycle. This in turn leads to a further increase of

driver temperature. An increase of temperature by about 100°C increases MOSFET resistance by

roughly 50%. This is a typical behavior of MOSFET switches. Therefore, under high duty cycle, high

load conditions, thermal characteristics have to be carefully taken into account, especially when

increased environment temperatures are to be supported. Refer the thermal characteristics and the

layout hints for more information. As a thumb rule, thermal properties of the PCB design become

critical for the QFN-36 at or above about 1000mA RMS motor current for increased periods of time.

Keep in mind that resistive power dissipation raises with the square of the motor current. On the

other hand, this means that a small reduction of motor current significantly saves heat dissipation

and energy.

An effect which might be perceived at medium motor velocities and motor sine wave peak currents

above roughly 1.2A peak is a slight sine distortion of the current wave when using spreadCycle. It

results from an increasing negative impact of parasitic internal diode conduction, which in turn

negatively influences the duration of the fast decay cycle of the spreadCycle chopper. This is, because

the current measurement does not see the full coil current during this phase of the sine wave,

because an increasing part of the current flows directly from the power MOSFETs’ drain to GND and

does not flow through the sense resistor. This effect with most motors does not negatively influence

the smoothness of operation, as it does not impact the critical current zero transition. The effect does

not occur with stealthChop.

3.7.1 Reduce Linear Regulator Power Dissipation

When operating at high supply voltages, as a first step the power dissipation of the integrated 5V

linear regulator can be reduced, e.g. by using an external 5V source for supply. This will reduce overall

heating. It is advised to reduce motor stand still current in order to decrease overall power

dissipation. If applicable, also use coolStep. A decreased clock frequency will reduce power dissipation

of the internal logic. Further a decreased chopper frequency also can reduce power dissipation.

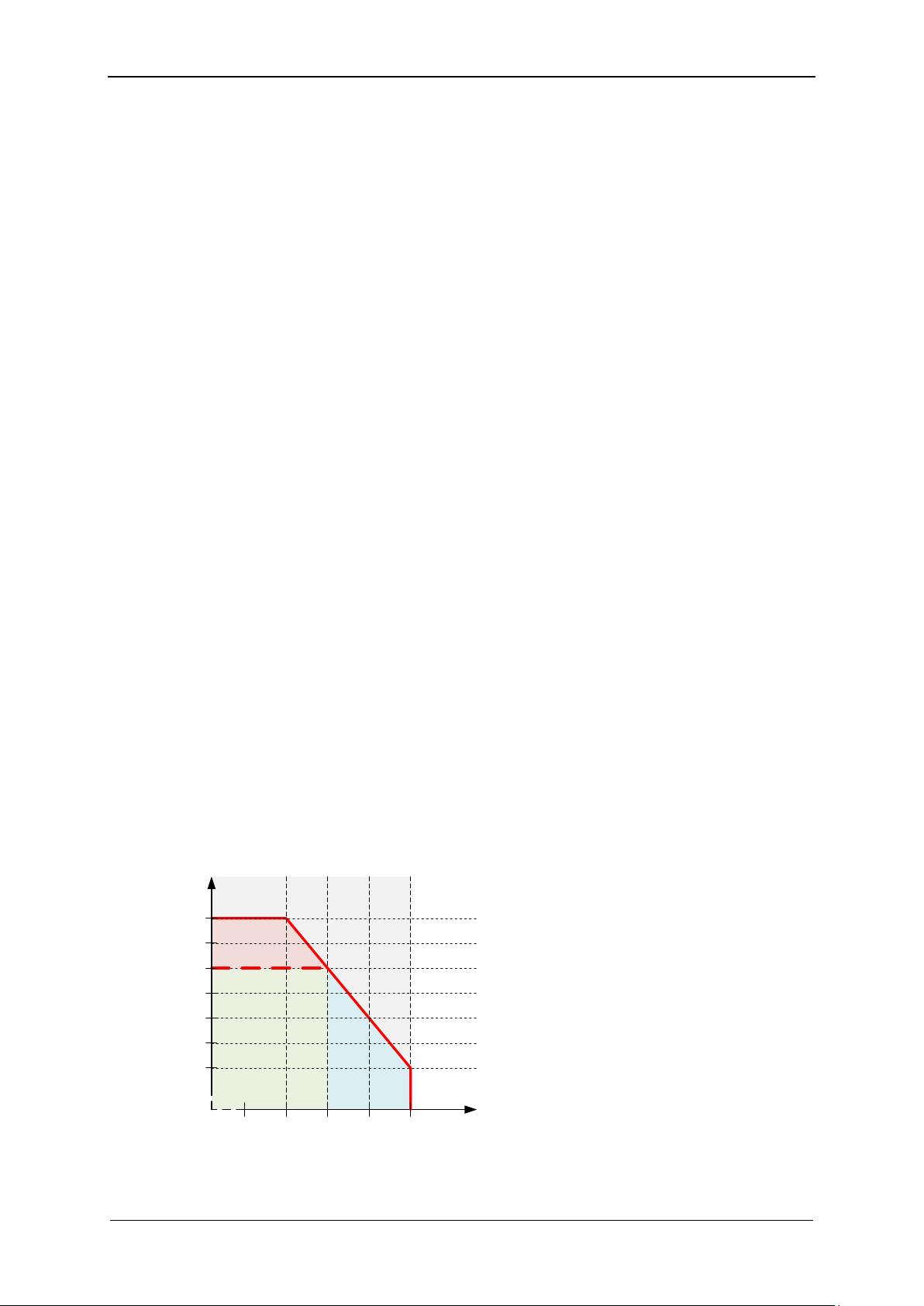

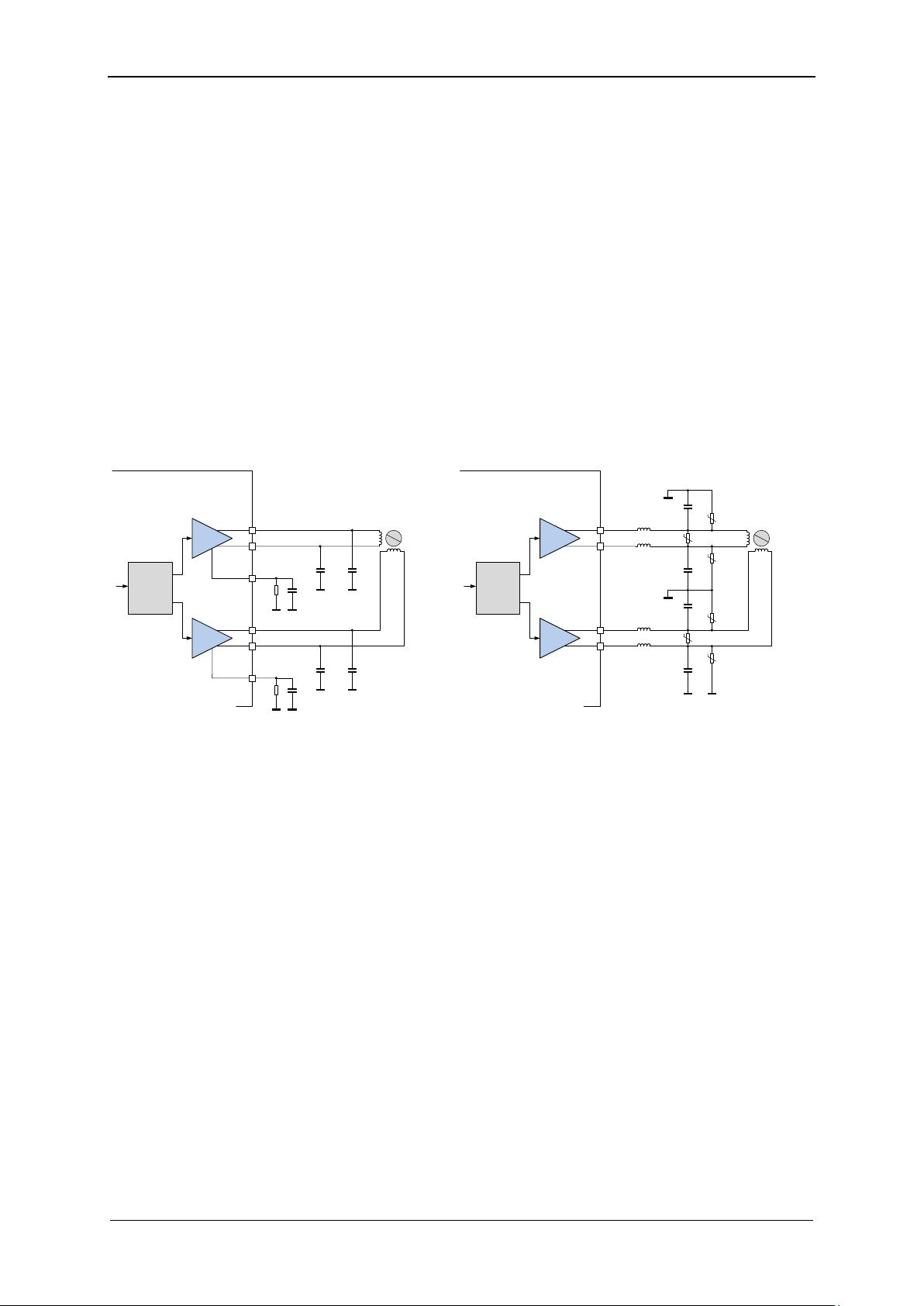

3.7.2 Operation near to / above 2A Peak Current

The driver can deliver up to 2.5A motor peak current. Considering thermal characteristics, this only is

possible in duty cycle limited operation. When a peak current up to 2.5A is to be driven, the driver

chip temperature is to be kept at a maximum of 105°C. Linearly derate the design peak temperature

from 125°C to 105°C in the range 2A to 2.5A output current (see Figure 3.8). Exceeding this may lead

to triggering the short circuit detection.