NR 490, Sec 2

8 Bureau Veritas January 2018

3 Steel and aluminium alloys materials

and connections

3.1 General requirements

3.1.1 This Article defines the main characteristics to take

into account for steels and aluminium alloys within the

scope of the determination of the hull scantling as defined

in the present Rules.

3.1.2 Materials with different characteristics may be con-

sidered, provided their specification (manufacture, chemi-

cal composition, mechanical properties, welding,...) is

submitted to the Society for approval.

3.1.3 Testing and manufacturing process

Materials are to be tested in compliance with the applicable

requirements of NR216 Materials and Welding.

The requirements of this Section presume that welding and

other cold or hot manufacturing processes (parent material

types and welding, preheating, heat treatment after weld-

ing,...) are carried out in compliance with current sound

working practice and the applicable requirements of NR216

Materials and Welding.

3.2 Steel structures

3.2.1 Steels for hull structures, forgings and castings

The characteristics of steels to be used in the construction of

ships are to comply with the applicable requirements of

NR216 Materials and Welding.

3.2.2 Mechanical characteristics

The mechanical characteristics of steels are to comply with

the requirements of NR467 Steel Ships, Pt B, Ch 4, Sec 1,

and in particular the:

• grade of steel to be used for the various strength mem-

bers of the structure

• steels for forging and casting.

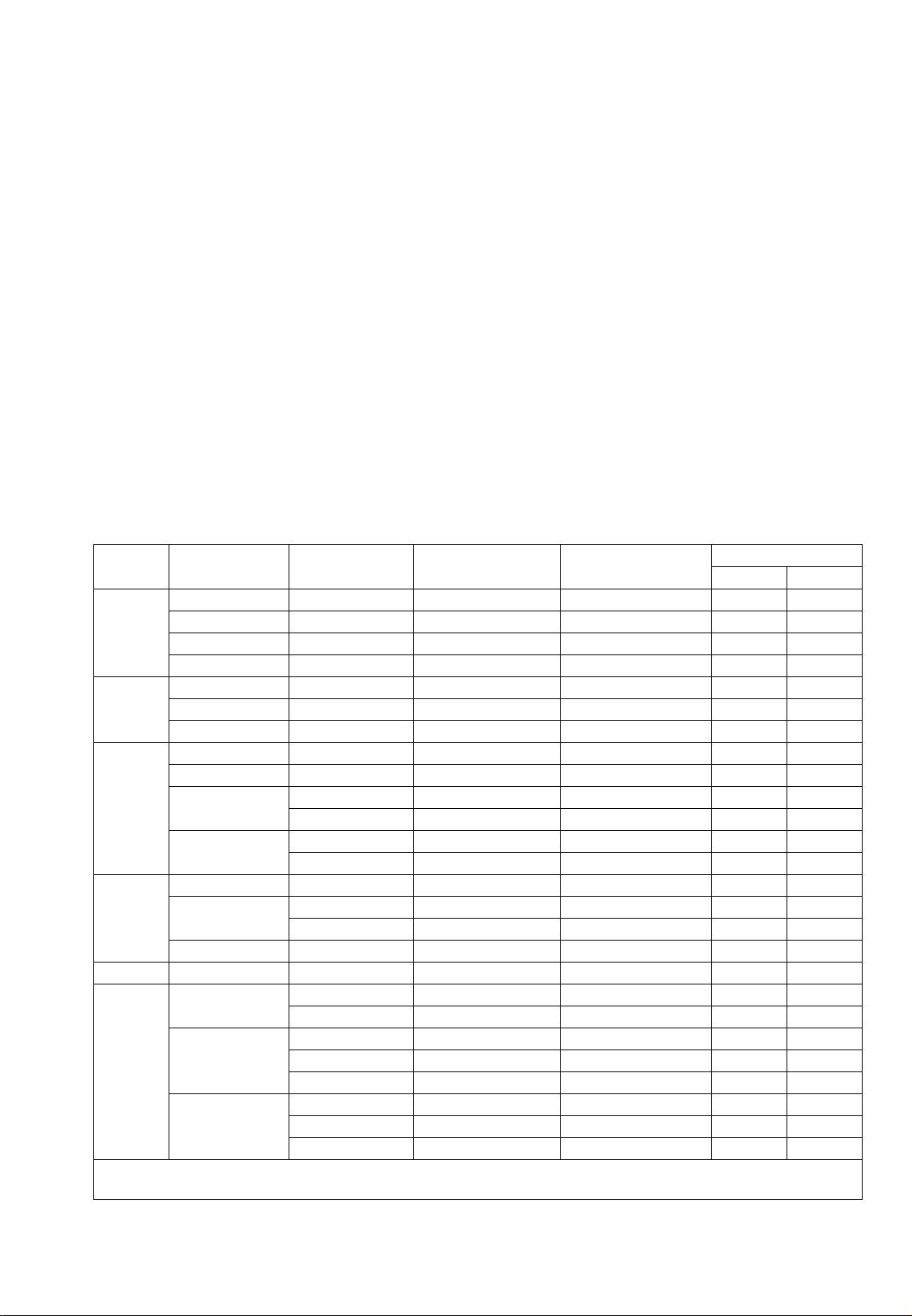

Tab 2 gives for information the mechanical properties of

steels currently used in the construction of ships.

Higher strength steels other than those indicated in Tab 2

are considered by the Society on a case-by-case basis.

When steels with a minimum specified yield stress R

eH

other

than 235 N/mm

2

are used, hull scantlings are to be deter-

mined by taking into account the material factor k defined

in [3.2.3].

3.2.3 Material factor k for scantlings of structural

members

The value of the material factor k to be introduced into for-

mulae to check structures given in this Section is a function

of the minimum yield stress R

eH

value specified for the steel

to be used.

Tab 3 shows the values of the material factor k to be taken

depending on the R

eH

value of the various high strength

steels for hull structures for which R

eH

390 N/mm

2

.

The use of steels for which R

eH

> 355 N/mm

2

will be con-

sidered in each separate case by the Society, which may

stipulate special acceptance conditions.

If, for special structures, the use of steels for which

R

eH

< 235 N/mm

2

, has been accepted by the Society, the

material factor is to be determined by:

k = 235 / R

eH

In the case where the use of steels with R

eH

values which are

intermediate between those indicated in Tab 3 is allowed,

the values of the material factor k may be determined by

means of linear interpolation.

3.2.4 Welding

The requirements for the scantling and joint design of

welded connection of ships built in steel materials are

defined in NR600, Chapter 6, Section 2.

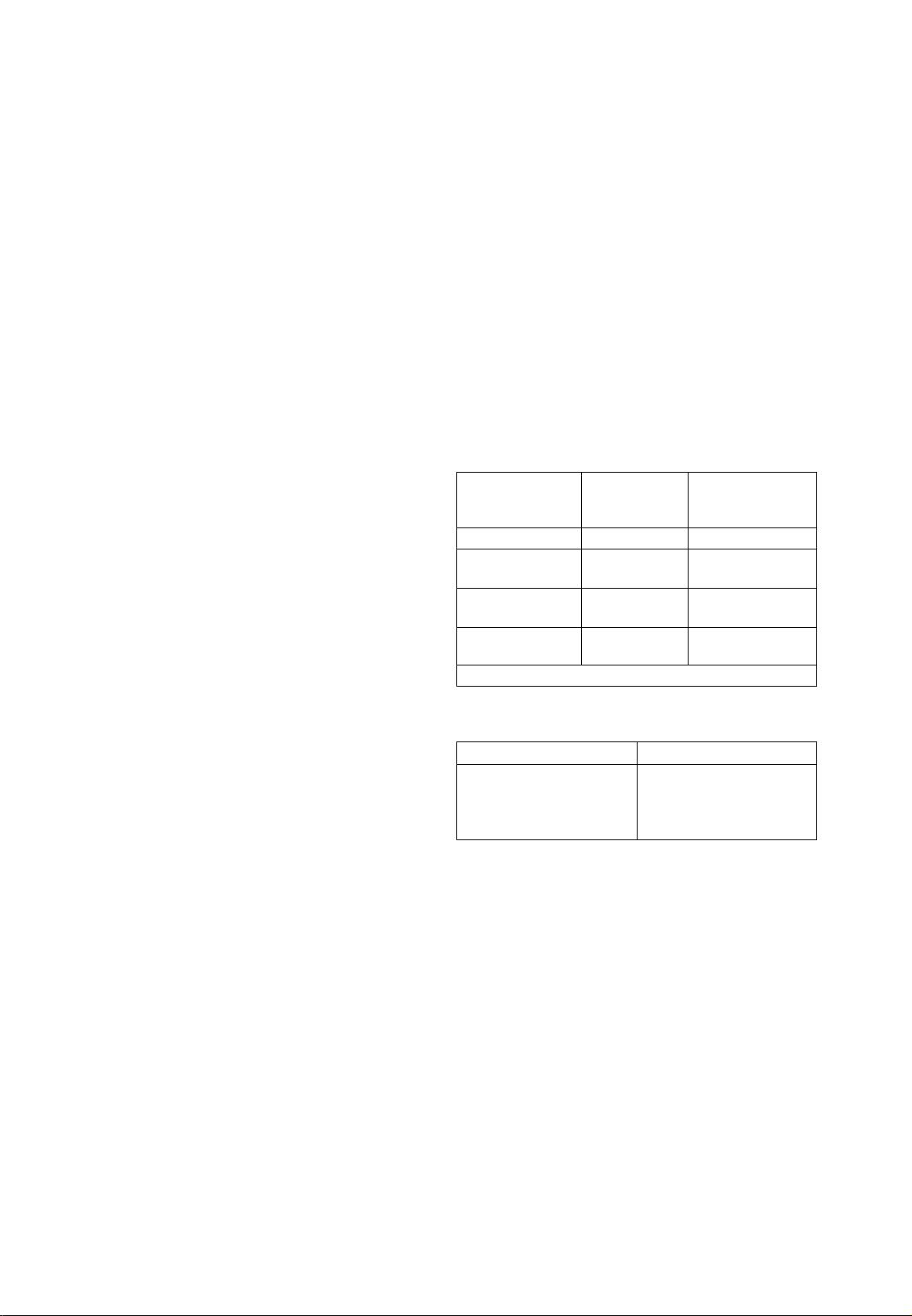

Table 2 : Mechanical characteristics

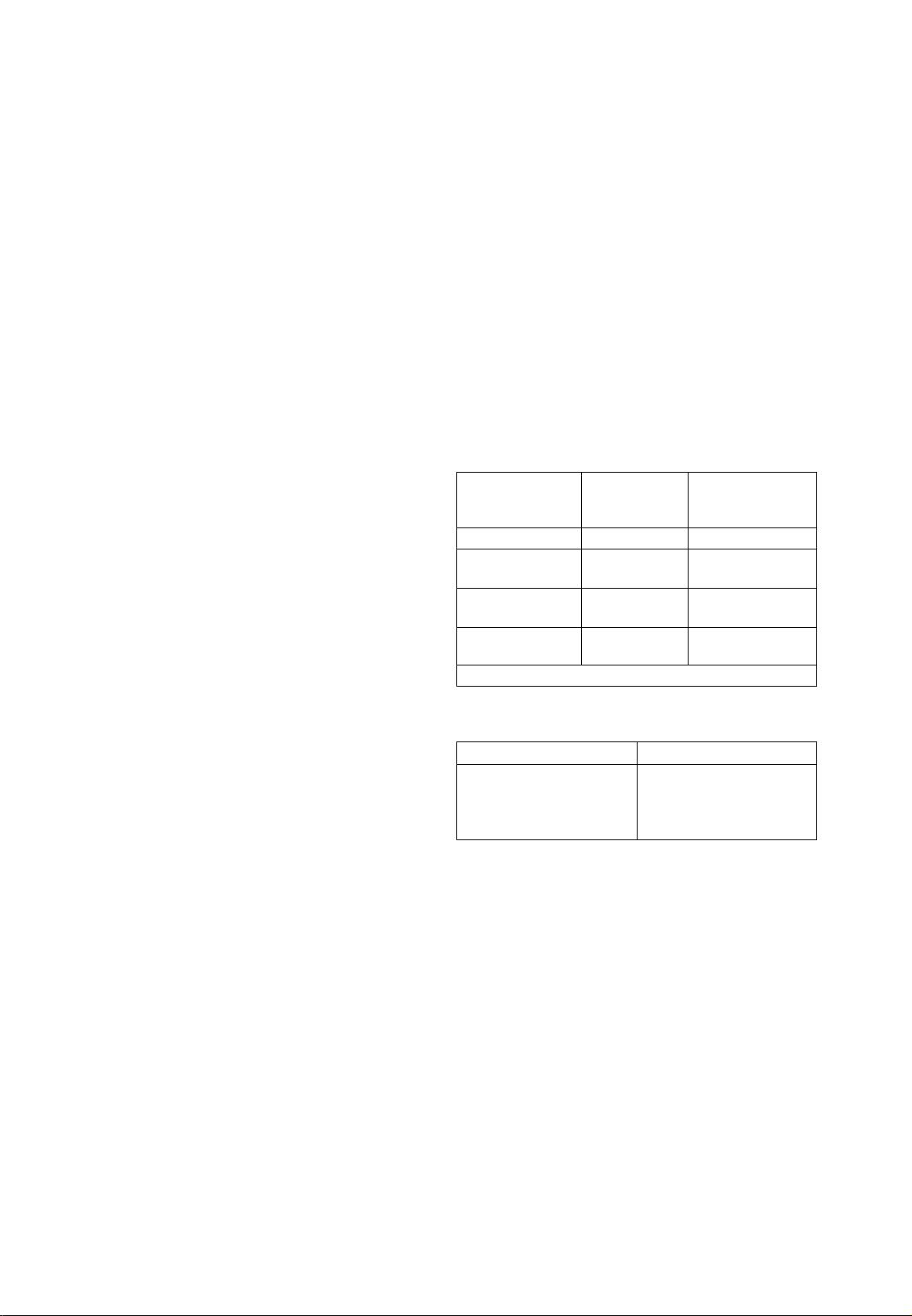

Table 3 : k factor

3.3 Aluminium alloy structures

3.3.1 Aluminium alloys for hull structures, forgings

and castings

The characteristics of aluminium alloys to be used in the

construction and their testing process are to comply with

the applicable requirements of the following Rules:

• NR216 Materials and Welding

• NR561 Aluminium Ships.

The list of aluminium alloys given in Tab 4 and Tab 5 for

information only is not exhaustive. Other aluminium alloys

may be considered, provided the specification (manufac-

ture, chemical composition, temper, mechanical properties,

welding, etc.) and the scope of application be submitted to

the Society for review.

Unless otherwise specified, the Young’s modulus for alu-

minium alloys is equal to 70000 N/mm

2

and the Poisson’s

ratio equal to 0,33.

Steel grades

t 100 mm

Minimum yield

stress R

eH

,

in N/mm

2

Ultimate minimum

tensile strength R

m

,

in N/mm

2

A-B-D-E 235 400 - 520

AH32-DH32-EH32

FH32

315 440 - 590

AH36-DH36-EH36

FH36

355 490 - 620

AH40-DH40-EH40

FH40

390 510 - 650

Note 1:

Refer to NR216 Materials and Welding, Ch 2, Sec 1, [2].

R

eH

(N/mm

2

)

k

235

315

355

390

1,00

0,78

0,72

0,70