Modified anti-windup scheme for PID controllers

A. Visioli

Abstract: An anti-windup scheme for proportional-integral-derivative controllers is presented.

The approach is based on the combined use of back-calculation and conditional integration anti-

windup techniques. In this way, the disadvantages that can hinder previously proposed strategies

are overcome. Specifically, the method can guarantee a satisfactor y performance for processes

with different normalised dead times, without the tuning of additional parameters being required.

Therefore, considering its simplicity, it is highly suitable for implementation in industrial

regulators.

1 Introduction

Despite the advent of many effective design methodologies

in the control field in recent years, propor tional-integral-

derivative (PID) controllers are undoubtedly still the most

adopted controllers in industrial settings, because they

provideacost=benefit ratio that is very difficult to amelio-

rate by other t ech niques. However, the performance of PID

controllers can be severely limited i n practical cases by the

presence of saturation of the actuators, which causes the

well-known phenomenon of integrator windup [1].

To deal with this problem, it is necessary, from a

theoretical point of view, to design the controller explicitly

taking into account the actuator c onstraints from the first

stage, e.g. refer ring to the nonlinear systems framework.

However, the overall design becomes mu ch more compli-

cated and therefore inappropriate in the PID control

context, where the ease of implementation has to be

preserved as a major feature. Therefore, the typical

method to deal with the integrator windup problem is to

tune the controller ignoring the actuator saturation and

subsequently to add an anti-windup compensator to

prevent the degradation of performance. In this context,

several techniques have been devised to de sign the

compensator [2, 3]. Basically, they b elong to two different

approaches, namely, conditional integration (in which the

value of the integrator is frozen when certain conditions

are verified) and back-calculation (in which the difference

between the controller output and the actual process input

is fed back to the integral terms) [4]. Note that the latter

case also includes the conditioning technique [5, 6] and

that a unified framework for the linear ti me-invariant anti-

windup schemes (including the use of an observer to

estimate the correct state of the controller [7, 8])has

been pre s en t ed in [9].

However, these techniq ues can s uffer from the presence

of a significant dead time in the process or, to deal with

processes with different normalised dead times, they might

require an extra tuning effort (see Section 2), which is

undesirable for industrial regulators. Therefore, it is

proposed to combine the different approaches (in a very

simple way) in order to overcome these problems.

2 Anti-windup strategies for PID controllers

2.1 Generalities

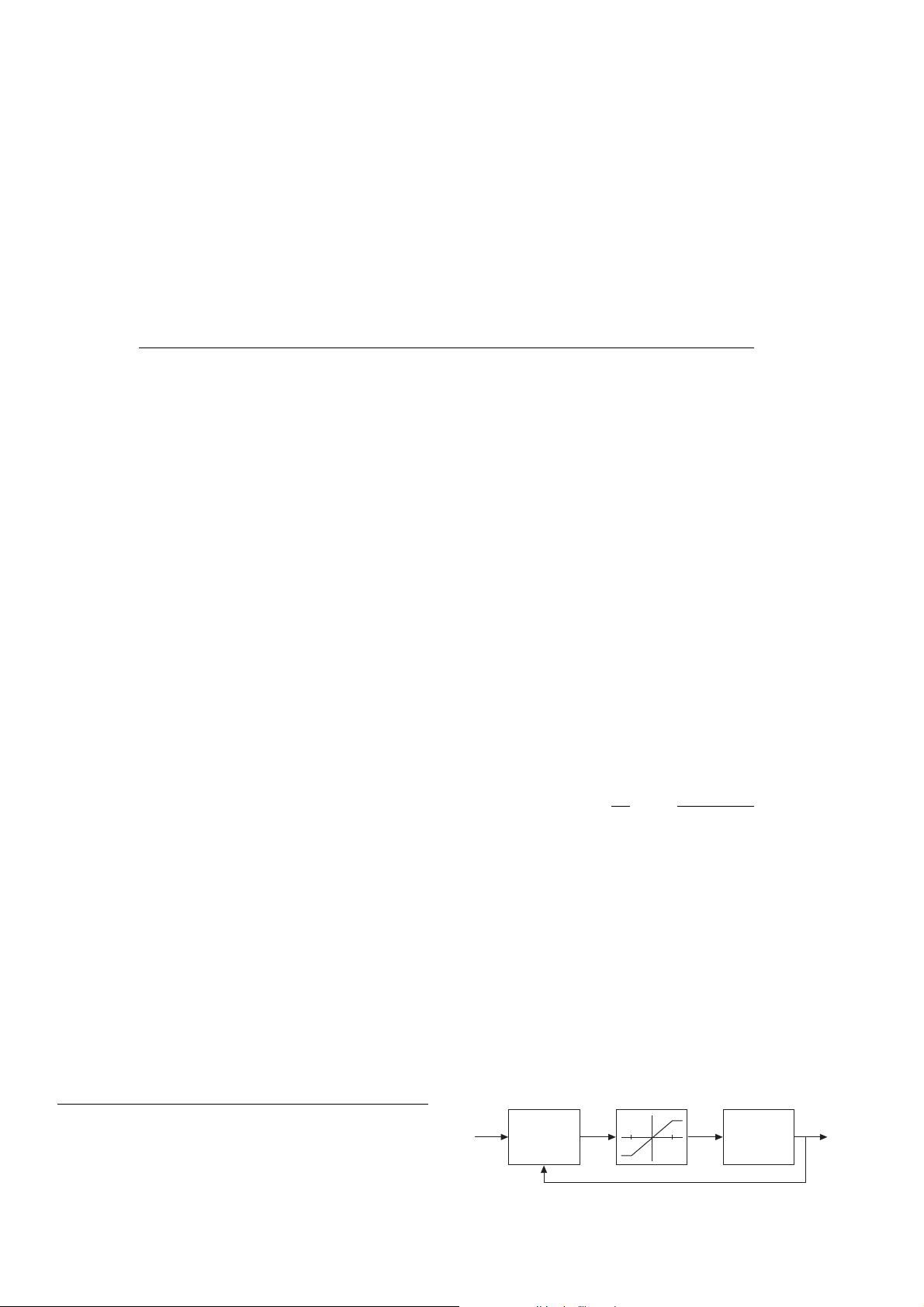

The int eg ra tor windu p is a phenom eno n that can oc cur in

the presence of a saturation of the process input. We refer

totheschemeofFig. 1,whereu is the controller output, u

s

is the actual process input, y is the process output, w is the

setpoint reference value and e i s the s ystem er ror. It is

assumed that a transition from the value y

0

to the value y

1

is

required for the system output and this determines the

amplitude of the step signal to be applied as input to

the closed-loop system. The PID controller is described by

the following expression (non-interacting form) in the

Laplace domain:

UðsÞ¼K

p

EðsÞþ

1

T

i

s

EðsÞ

sT

d

1 þ sðT

d

=NÞ

Y ðsÞ

ð1Þ

where K

p

, T

i

and T

d

are the proportional gain and the

integral and derivative time constants respectively, and N is

usually set between five and 20.

The integrator w indup occurs when a step change in w

causes the actuator to saturate. In this case the system error

decreases more slowly than in the ideal case (when there is

no input limitation) and therefore the value of the integral

term becom es large. Thus, even when the value of y attains

that of w, the controller still saturates due to the integral

term and this generally leads to large overshoots and

settling times.

It has to be noted that the integrator windup m ainly

occurs when a step is applied to the reference setpoint

signal rather than to the manipulated variable (i.e. in the

# IEE, 2003

IEE Proceedings online no. 20020769

DOI: 10.1049/ip-cta:20020769

Paper first received 22nd April and in revised form 20th September 2002

The author is with the Dipartimento di Elettronica per l’Automazione,

University of Brescia, Via Branze 38, 25123 Brescia, Italy

µ

s

min

µ

s

max

u

s

u

PID

wy

process

Fig. 1 General control scheme

IEE Proc.-Control Theory Appl., Vol. 150, No. 1, January 2003 49