3

Principles of Computer Science

3-D printing

object is then cleaned and cured by UV. This AM

technique is also called vat photopolymerization

because it takes place within a vat of liquid resin.

Various types of SLA printing processes have been

given alternate names, such as “photofabrication”

and “photo-solidification.”

Powder-Based 3-D Printing

In the 1980s, engineers at the University of Texas cre-

ated an alternate process that uses powdered solids

instead of liquid. Selective layer sintering (SLS), or

powder bed fusion, heats powdered glass, metal, ce-

ramic, or plastic in a powder bed until the material

is “sintered.” To sinter something is to cause its par-

ticles to fuse through heat or pressure without lique-

fying it. A laser is used to selectively sinter thin layers

of the powder, with the unfused powder underneath

giving structural support. The platform is lowered

and the powder compacted as the laser passes over

the object again.

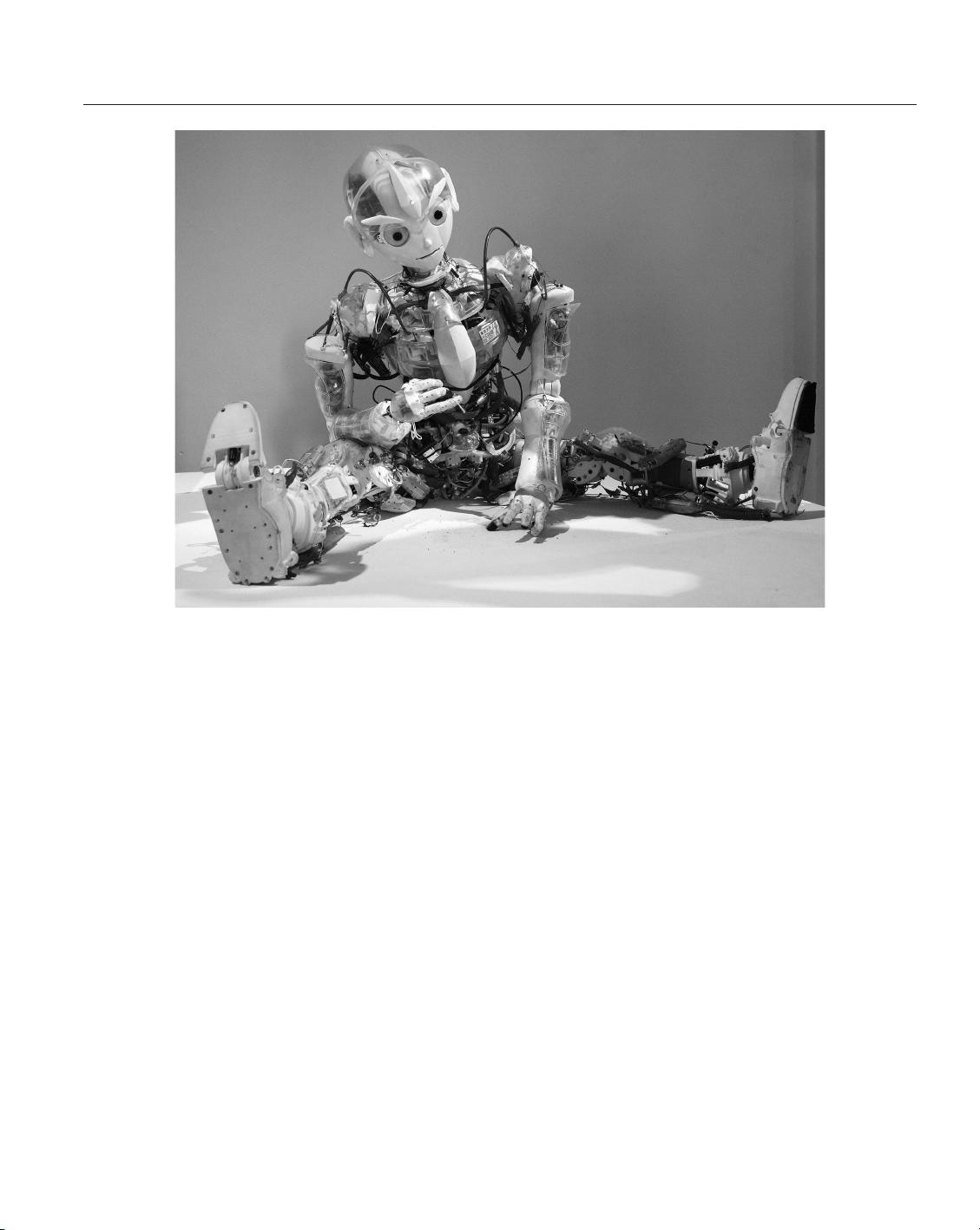

Extrusion Printing

Material extrusion printing heats plastic or polymer

filament and extrudes it through nozzles to deposit a

layer of material on a platform. One example of this

process is called fused deposition modeling (FDM).

As the material cools, the platform is lowered and

another layer is added atop the last layer. Creating

extruded models often requires the use of a struc-

tural support to prevent the object from collapsing.

Extrusion printing is the most affordable and com-

monly available 3-D printing process.

Emerging and Alternative Methods

Several other 3-D printing methods are also

emerging. In material jetting, an inkjet printer head

deposits liquefied plastic or other light-sensitive ma-

terial onto a surface, which is then hardened with UV

light. Another inkjet printing technique is binder

jetting, which uses an inkjet printer head to deposit

drops of glue-like liquid into a powdered medium.

The liquid then soaks into and solidifies the medium.

In directed energy deposition (DED), metal wire or

powder is deposited in thin layers over a support be-

fore being melted with a laser or other heat source.

Sheet lamination fuses together thin sheets of paper,

metal, or plastic with adhesive. The resulting object

is then cut with a laser or other cutting tool to refine

the shape. This method is less costly but also less ac-

curate than others.

The Future of 3-D Printing

While AM techniques have been in use since the

1980s, engineers believe that the technology has not

yet reached its full potential. Its primary use has been

in rapid prototyping, in which a 3-D printer is used to

quickly create a 3-D model that can be used to guide

production. In many cases, 3-D printing can create

objects that are stronger, lighter, and more customiz-

able than objects made through machining. Printed

parts are already being used for planes, race cars,

medical implants, and dental crowns, among other

items. Because AM wastes far less material than sub-

tractive manufacturing, it is of interest for conserva-

tion, waste management, and cost reduction. The

technology could also democratize manufacturing,

as small-scale 3-D printers allow individuals and small

businesses to create products that traditionally re-

quire industrial manufacturing facilities. However,

intellectual property disputes could also occur more

often as AM use becomes more widespread.

—Micah L. Issitt

Bibliography

“About Additive Manufacturing.” Additive

Manufacturing Research Group. Loughborough U,

2015. Web. 6 Jan. 2016.

Hutchinson, Lee. “Home 3D Printers Take Us on a

Maddening Journey into Another Dimension.” Ars

Technica. Condé Nast, 27 Aug. 2013. Web. 6 Jan.

2016.

“Knowledge Base: Technologies in 3D Printing.”

DesignTech. DesignTech Systems, n.d. Web. 6 Jan.

2016.

Matulka, Rebecca. “How 3D Printers Work.” Energy.

gov. Dept. of Energy, 19 June 2014. Web. 6 Jan.

2016.

“The Printed World.” Economist. Economist

Newspaper, 10 Feb. 2011. Web. 6 Jan. 2016.

“3D Printing Processes: The Free Beginner’s Guide.”

3D Printing Industry. 3D Printing Industry, 2015.

Web. 6 Jan. 2016.

Principles of_Computer_A-B_001-048.indd 3 10/10/16 7:58 PM