■ 8

IEEE CIRCUITS & DEVICES MAGAZINE

■

MAY/JUNE 2005

however, were still too large to make APS commercially viable.

With the advent of deep submicron CMOS and integrated

microlens technologies, APS has made CMOS image sensors a

viable alternative to CCDs. Taking further advantage of tech-

nology scaling, the digital pixel sensor (DPS), first reported in

[6], integrates an ADC at each pixel. The massively parallel

conversion and digital readout provide very high speed read-

out, enabling new applications such as wider dynamic range

(DR) imaging, which is discussed later in this article.

Many of the differences between CCD and CMOS image

sensors arise from differences in their readout architectures.

In a CCD [see Figure 4(a)], charge is shifted out of the array

via vertical and horizontal CCDs, converted into voltage via a

simple follower amplifier, and then serially read out. In a

CMOS image sensor, charge voltage signals are read out one

row at a time in a manner similar to a random access memory

using row and column select circuits [see Figure 4(b)]. Each

readout architecture has its advantages and disadvantages.

The main advantage of the CCD readout architecture is that it

requires minimal pixel overhead, making it possible to design

image sensors with very small pixel sizes. Another important

advantage is that charge transfer is passive and therefore does

not introduce temporal noise or pixel to pixel variations due

to device mismatches, known as fixed-pattern noise (FPN).

The readout path in a CMOS image sensor, by comparison,

comprises several active devices that introduce both temporal

noise and FPN. Charge transfer readout, however, is serial

resulting in limited readout speed. It is also high power due to

the need for high-rate, high-voltage clocks to achieve near-

perfect charge transfer efficiency. By comparison, the random

access readout of CMOS image sensors provides the potential

for high-speed readout and window-of-interest operations at

low power consumption. There are several recent examples of

CMOS image sensors operating at hundreds of frames per sec-

ond with megapixel or more resolution [7]–[9]. The high-

speed readout also makes CMOS image sensors ideally suited

for implementing very high-resolution imagers with multi-

megapixel resolutions, especially for

video applications. Recent examples of

such high-resolution CMOS imagers

include the 11-megapixel sensor used

in the Canon EOS-1 camera and the 14-

megapixel sensor used in the Kodak

DCS camera.

Other differences between CCDs and

CMOS image sensors arise from differ-

ences in their fabrication technologies.

CCDs are fabricated in specialized tech-

nologies solely optimized for imaging

and charge transfer. Control over the

fabrication technology also makes it

possible to scale pixel size down with-

out significant degradation in perfor-

mance. The disadvantage of using such

specialized technologies, however, is

the inability to integrate other camera

functions on the same chip with the sensor. CMOS image sen-

sors, on the other hand, are fabricated in mostly standard

technologies and thus can be readily integrated with other

analog and digital processing and control circuits. Such inte-

gration further reduces imaging system power and size and

enables the implementation of new sensor functionalities, as

will be discussed later.

Some of the CCD versus CMOS comparison points made

here should become clearer as we discuss image sensor tech-

nology in more detail.

Photodetection

The most popular types of photodetectors used in image sen-

sors are the reverse-biased positive-negative (PN) junction

photodiode and the P

+

/N/P pinned diode (see Figure 5). The

structure of the pinned diode provides improved photorespon-

sivity (typically with enhanced sensitivity at shorter wave-

lengths) relative to the standard PN junction [10]. Moreover,

the pinned diode exhibits lower thermal noise due to the pas-

sivation of defect and surface states at the Si/SiO

2

interface, as

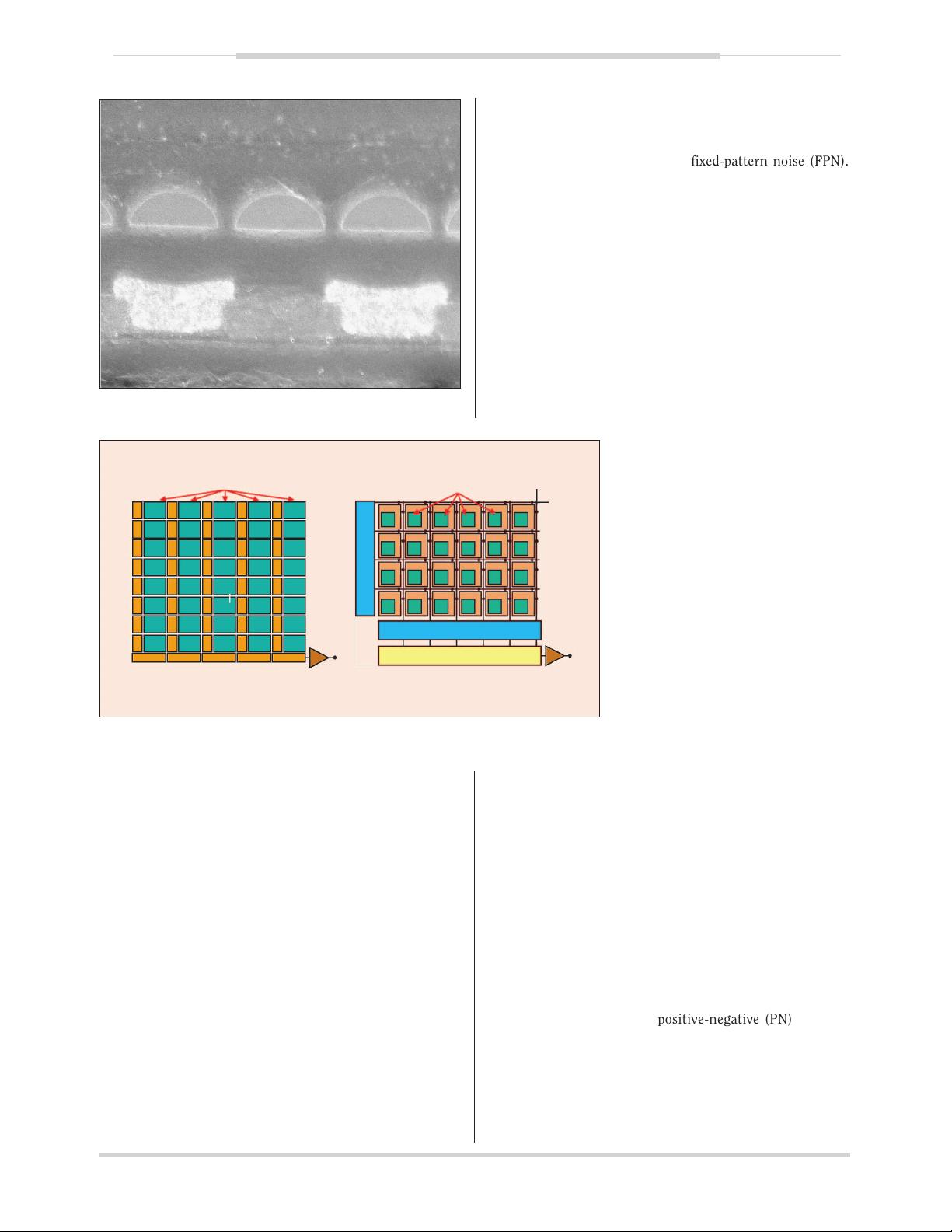

3. A cross-section SEM photograph of an image sensor showing the

microlens and CFA deposited on top of the photodetectors.