COL 10(1), 013103(2012) CHINESE OPTICS LETTERS January 10, 2012

Thinning and polishing of cross-section of depth-graded

WSi

2

/Si multilayer for linear zone plate application

Qiushi Huang (黄黄黄秋秋秋实实实)

1, 2

, Jingtao Zhu (朱朱朱京京京涛涛涛)

1, 2∗

, Haochuan Li (李李李浩浩浩川川川)

1, 2

, Zhengxiang Shen (沈沈沈正正正祥祥祥)

1, 2

,

Xiaoqiang Wang (王王王晓晓晓强强强)

1, 2

, Zhanshan Wang (王王王占占占山山山)

1, 2

, and Yongjian Tang (唐唐唐永永永建建建)

3

1

Institute of Precision Optical Engineering, Physics Department, Tongji University, Shanghai 200092, China

2

Shanghai Key Lab oratory of Special Artif icial Microstructure Materials and Technology, Tongji University,

Shanghai 200092, China

3

Research Center of Laser Fusion, China Academy of Engineering Physics, Mianyang 621900, China

∗

Corresp onding author: jtzhu@tong ji.edu.cn

Received April 11, 2011; accepted June 14, 2011; posted online August 24, 2011

A linear zone plate named multilayer laue lens (MLL) is fabricated using a depth-graded multilayer struc-

ture. The lens shows considerable potential in focusing an X-ray beam into a nanometer scale with high

efficiency. In this letter, a depth-graded multilayer consisting of 324 alternating WSi

2

and Si layers with

a total thickness of 7.9 µm is deposited based on the thickness sequence according to the demands of

the zone plate law. Subsequently, the multilayer sample is sliced and thinned to an ideal depth along

the cross-section direction using raw abrasives and diamond lapping. Finally, the cross-section is polished

by a chemical mechanical polishing (CMP) technique to remove the damages and improve the surface

smoothness. The final depth of the MLL is approximately 7 µm with an achieved aspect ratio greater

than 400. Results of scanning electron microscopy (SEM) and atomic force microscopy (AFM) indicate

that interfaces are sharp, and the multilayer structure remains undamaged after the thinning and polishing

processes. The surface roughness achieved is 0.33 nm.

OCIS co des: 310.3840, 340.7460, 310.1860.

doi: 10.3788/COL201210.013103.

High-brilliance synchrotron X-ray sources enhance the

feasibility of nanobeam focusing, which is helpful to X-

ray microscopy analysis under higher resolution. Several

components have been developed to focus X-rays into

a nanobeam, such as Kirkpatrick-Baez mirrors

[1]

, com-

pound refractive lens

[2]

, Fresnel zone plate lens

[3]

, and

graded multilayer mirrors

[4]

. Fresnel zone plates have

been demonstrated as powerful focusing lenses in X-ray

microscopy applications. However, for hard X-rays, the

aspect ratio of a zone plate (ratio of the depth of a zone

plate to its outermost zone width) becomes exceedingly

large that could not be achieved using traditional litho-

graphic techniques. A novel linear zone plate, named

multilayer laue lens (MLL), is developed by depositing

the depth-graded multilayer reversely on flat substrates

and subsequently slicing and polishing the lens to achieve

a larger aspect ratio. As a result, MLL has shown capa-

bility to provide a significantly higher focusing efficiency

and resolution especially in hard X-ray regions

[5,6]

. Fur-

thermore, the outermost layers (i.e., the thinnest layers)

of MLL, which determine the resolution, are firstly de-

posited on a substrate to control the thicknesses and

quality of the critical layers better. A MLL structure

with an outermost layer thickness of 5 nm has focused

the 19.5-keV X-ray into a line focus of 16 nm, with an

efficiency of 31%

[7]

.

In this letter, a MLL is designed and a thickness-graded

multilayer with 324 layers is successfully dep osited using

WSi

2

and Si alternately. The detailed slicing, thinning,

and polishing processes of the multilayer sample are re-

ported to form a nearly perfect linear zone plate with a

high aspect ratio.

The MLL was designed at energy E=8 keV, with a

focal length of 2.04 mm. According to the zone plate

law, the depth-graded multilayer should consist of 324

alternating WSi

2

and Si layers with a total thickness

of 7.9 µm. The outermost layer thickness of the zone

plate is 15 nm. In the present study, the layer thickness

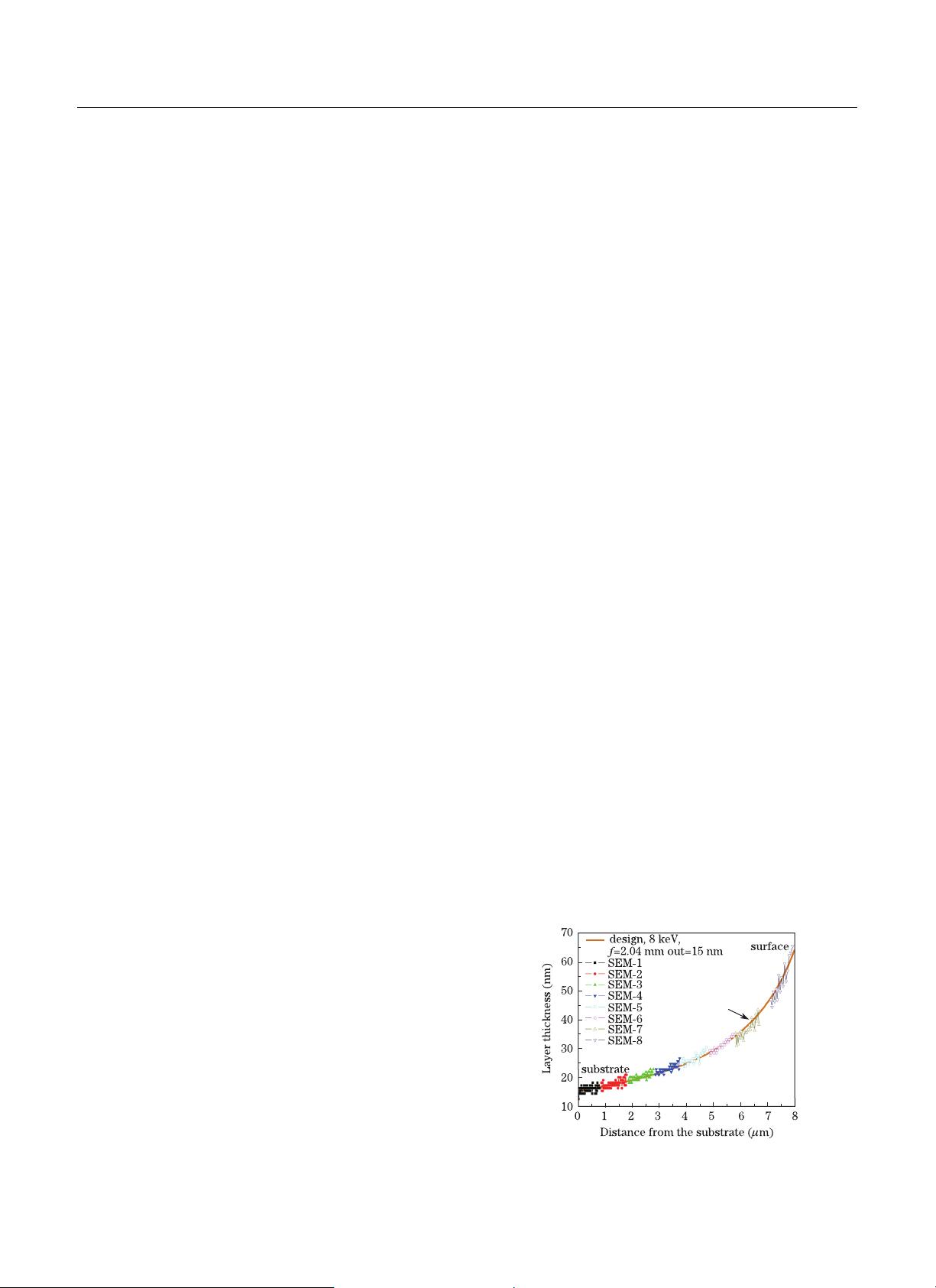

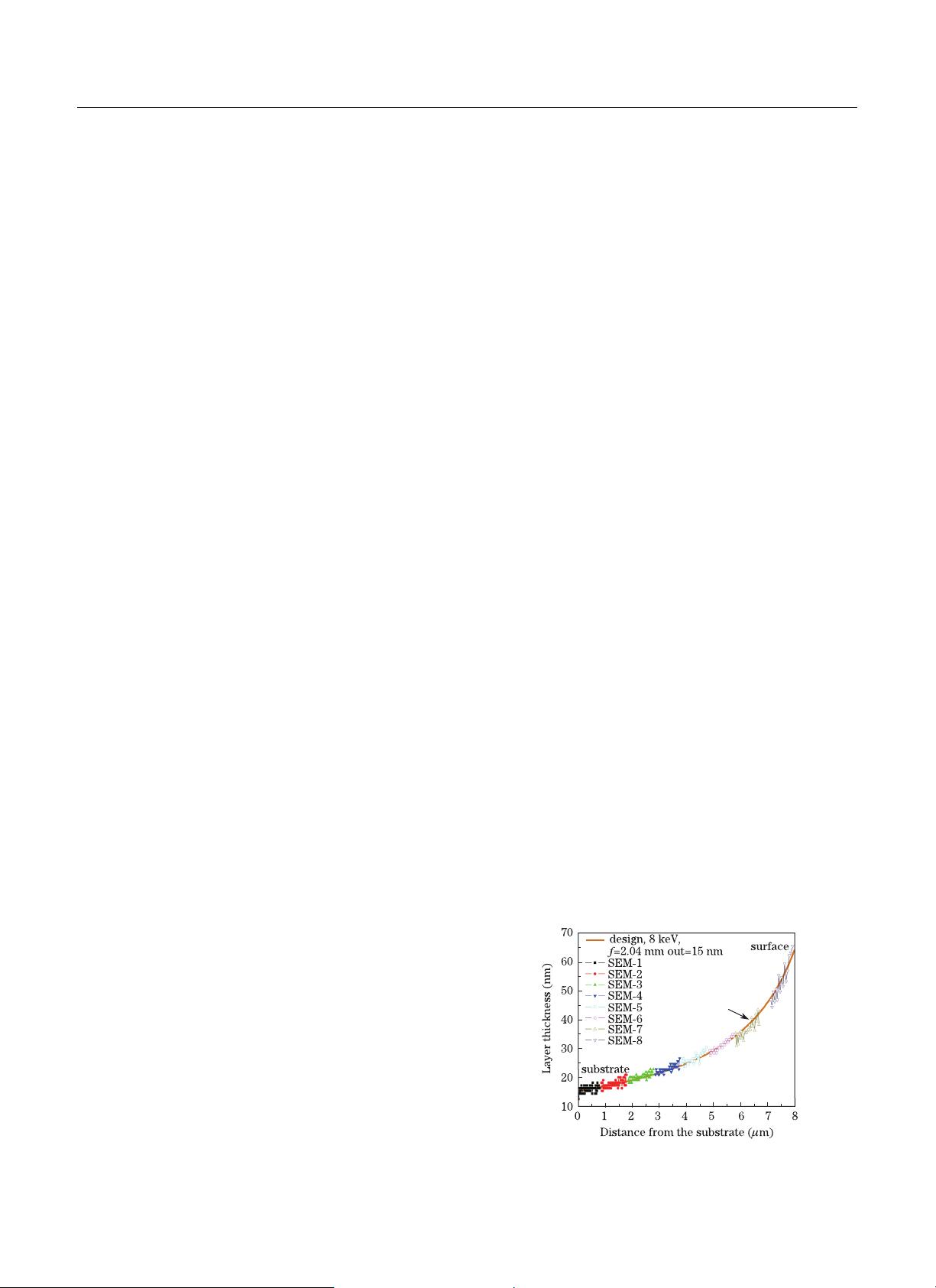

increases from 15 to 65 nm as shown in Fig. 1.

The material combination of WSi

2

/Si was chosen to

fabricate the MLL because of its stable stress property

[8]

.

To ensure better control of the position and quality of the

outermost layers, which determine the focusing property,

the multilayer was deposited reversely on a super pol-

ished Si(100) substrate using direct current magnetron

sputtering technology

[9,10]

. After deposition, the cross-

section of the multilayer was observed by scanning elec-

tron microscopy (SEM), as shown in Fig. 2. Figure

2(a) is an image of the entire cross-section, and Fig. 2(b)

Fig. 1. Designed and deposited multilayer structure of MLL.

The total number of layers is 324 with a total thickness of 7.9

µm.

1671-7694/2012/013103(4) 013103-1

c

° 2012 Chinese Optics Letters