178

HVAC&R

RESEARCH

Lee et al. (1996a) used two methods to detect eight different faults (mostly abrupt faults) in a

laboratory test

AHLJ.

The first method uses discrepancies between measured and expected vari-

ables (residuals) to detect the presence of a fault. The expected values are estimated at nominal

operating conditions. The second method compares parameters estimated using autoregressive

moving average with exogenous input

(ARMX)

and

ARX

models with the normal (or expected)

parameters to detect faults. The faults evaluated included complete failure of the supply and

return fans, complete failure of the chilled-water circulation pump, stuck cooling-coil valve,

complete failure of temperature sensors, complete failure of the static pressure sensor, and fail-

ure of the supply and return air fan flow stations. Because each of the eight faults has a unique

signature, no separate diagnosis is necessary.

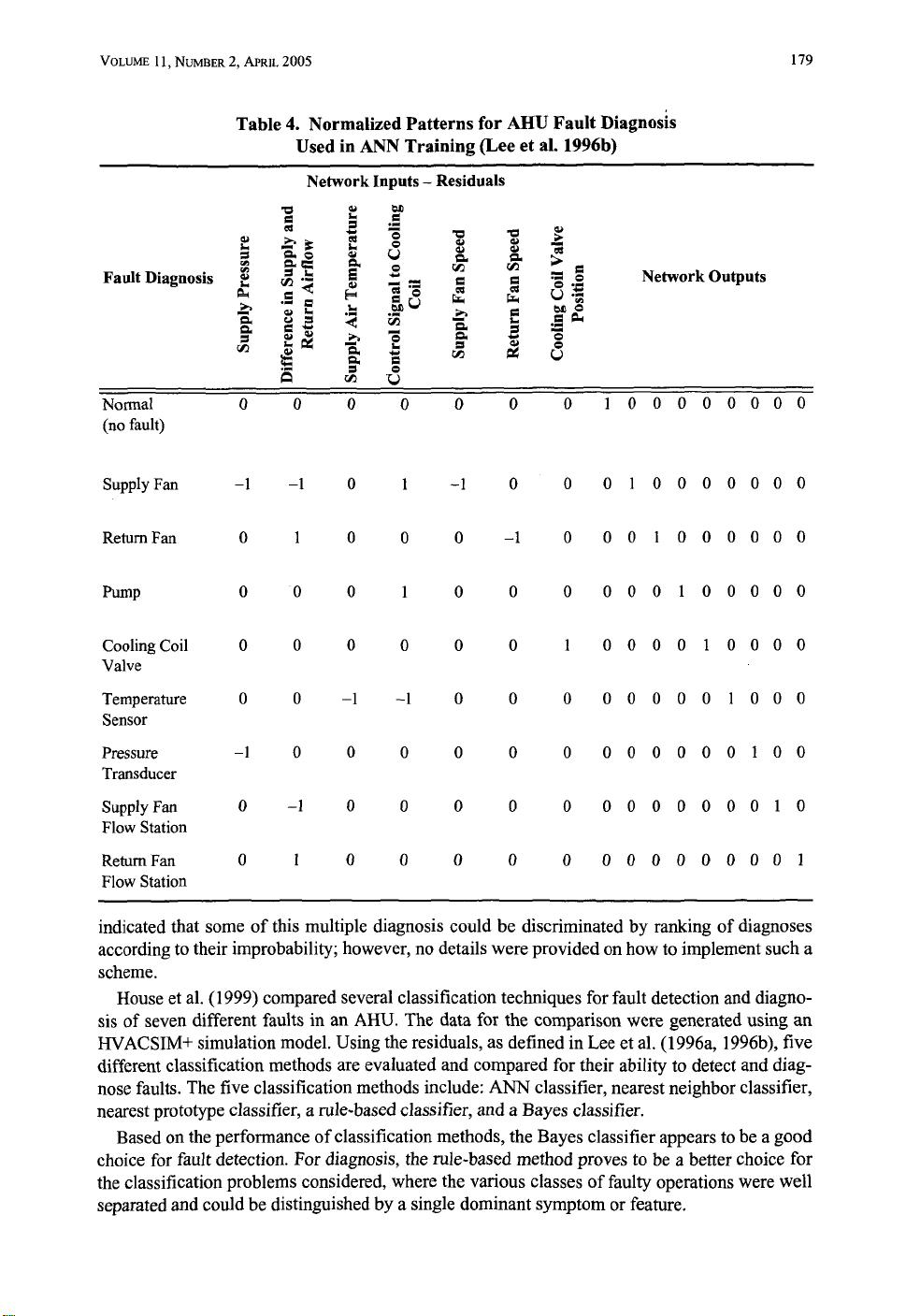

Lee et al. (1996b) used an

ANN

to detect the same faults described previously (Lee et al.

1996a). The

ANN

was trained using the normal data and data that represented each of the eight

faults. Inputs to the

ANN

were values for seven normalized residuals, and the outputs were nine

values that constitute patterns that represent the normal mode and the eight fault modes. Instead

of generating the training data with faults, idealized training patterns were specified by consider-

ing the dominant symptoms of each fault. For example, supply fan failure implies that the sup-

ply fan speed is zero, the supply air pressure is zero, the supply fan control signal is maximum,

and the difference between the flow rates in the supply and return ducts is zero. Using similar

reasoning, a pattern

of

dominant training residuals was generated for each fault (see Table

4).

A

dominant symptom residual is assigned a value of +1 if the residual is positive and -1 if the

residual is negative; all other residuals are assigned a value of

O.

The

ANN

was trained using the

pattern shown in Table

4.

Normalized residuals were calculated for faults that were artificially

generated in the laboratory

AHU.

The normalized residuals vector at each time step was then

used with the trained

ANN

to identify the fault. Although the

ANN

was successful in detecting

the faults from laboratory data, it

is

not clear how successful this method would be in general

because the faults generated in the laboratory setting were severe and without noise.

Lee et al. (1997) extended the previous work described in Lee et al. (1996b). In the 1997 anal-

ysis, Lee et al. (1997) used two

ANN

models to detect and diagnose faults. The

AHü

is decom-

posed into various subsystems such as the pressure control subsystem, the flow-control

subsystem, the cooling-coil subsystem, and the mixing-damper subsystem. The first

ANN

model is trained to identify the subsystem in which a fault occurs, while the second

ANN

model

is trained to diagnose the specific cause of a fault at the subsystem level.

An

approach similar to

the one used in Lee et al. 1996b is used to train both

ANN

models. Lee et al. (1997) note that this

two-stage approach simplifies generalization by replacing a single

ANN

that encompasses all

considered faults with a number of less complex

ANNs,

each one dealing with a subset of the

residuals and symptoms. Although 11 faults are identified for detection and diagnosis, fault

detection and diagnosis are presented for only one fault in the paper.

Peitsman and Soethout

(1

997) used several different

ARX

models to predict the performance

of an

AHü

and compared the predictions to measured values to detect faults. The training data

for the

ARX

models were generated using

HVACSIM+.

The

AHü

is modeled at two levels. The

first level is the system level, where the complete AHü is modeled with one

ARX

model. The

second level

is the component level, where the

AHU

is subdivided into several subsystems such

as the return fan, the mixing box, and the cooling coil. Each component is modeled with a sepa-

rate

ARX

model. The first level

ARX

model is used to detect a problem and the second level

models are used to diagnose the problem. Most abrupt faults were correctly identified and diag-

nosed, while slowly evolving faults were not detected. There is a potential for a conflict between

the two levels with this approach; for example, the top-level

ARX

model could detect a fault

with the

AHU,

while the second-level

ARX

models do not indicate any faults. Furthermore,

there is a potential for multiple diagnoses at the second level. Peitsman and Soethout (1997)

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:28:15 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---