Locally Weighted Canonical Correlation Analysis for Nonlinear

Process Monitoring

Qingchao Jiang and Xuefeng Yan*

Key Laboratory of Advanced Control and Optimization for Chemical Processes of Ministry of Education, East China University of

Science and Technology, Shanghai 200237, P. R. China

*

S

Supporting Information

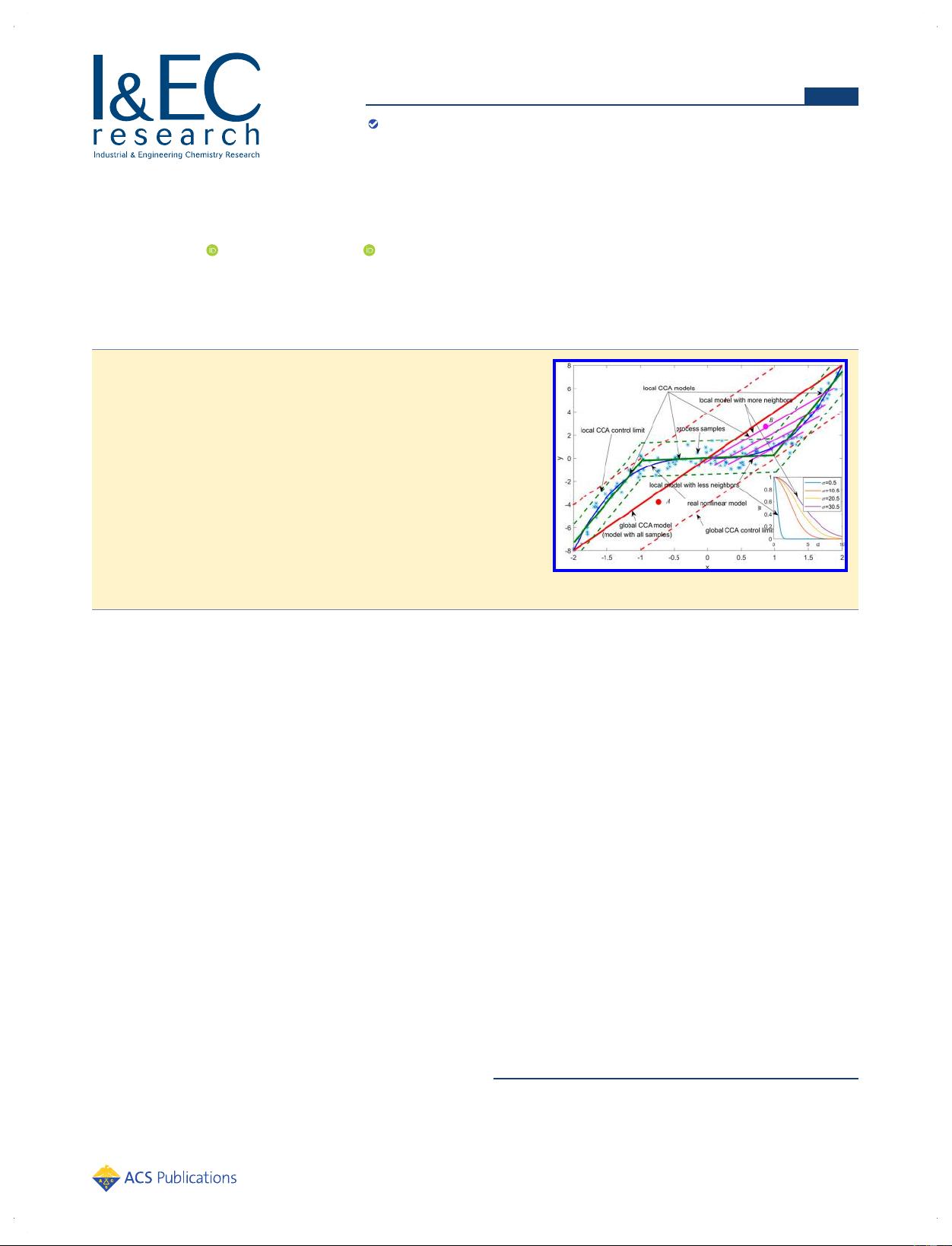

ABSTRACT: A locally weighted canonical correlation analysis (LWCCA)

method is proposed to achieve efficient nonlinear process monitoring.

The basic idea of the LWCCA is to approximate a nonlinear process

through several local linear canonical correlation analysis (CCA) models, in

which the determination of sample weights is a key step. Slowly decreasing

weights will ignore the local behaviors, whereas rapidly decreasing weights

will lead to significant false alarms. A randomized algorithm-based approach

is proposed to determine the tunable parameter for calculating the weights.

Thus, the LWCCA model explores as much local behavior as possible with

the false alarm performance guaranteed. When a local CCA model that

characterizes the process input and process output correlation is estab-

lished, optimal fault detection residuals are generated, and monitoring sta-

tistics are established. Two experimental studies are conducted through

which the efficiency of the LWCCA method is verified.

■

INTRODUCTION

Process monitoring is crucial in maintaining the long-term safe

operation of a production plant. Rapid advancement of data

collecting and transmitting techniques has created an abundance

of process data that contain meaningful available process infor-

mation.

1−3

Especially, data-driven multivariate analysis (MVA)

methods play a more important role in process monitoring.

4−9

Generally, a classical MVA monitoring method follows offline

modeling with online monitoring procedures. During the offline

modeling, a multivariate data analysis technique is employed to

explore the relationship among variables and to construct the

feature spaces for monitoring. In the online monitoring proce-

dure, a query sample is projected into the monitoring spaces, and

the process status is determined according to monitoring

statistics.

Principal component analysis (PCA), partial least-squares

(PLS), and canonical correlation analysis (CCA) are the basic

MVA methods. PCA focuses on the variable relationships of the

entire process (without discriminating process input and

output).

10−12

It constructs a dominant subspace and a residual

subspace according to the features’ importance for reconstruct-

ing the original data. PLS focuses on the quality-related process

monitoring.

13−15

It constructs the quality-related subspace and

the residual subspace according to their relationship with

difficult-to-measure quality variables. A fault in the quality-

related subspace is important, because the fault will generally

affect the production quality. CCA explores the correlation

between two sets of variables. It is generally used in two different

ways for process monitoring, as follows: one way focuses on the

relation between the process input and process output; and the

other way focuses on the relation between two coupled

units.

16−20

It is proven that the CCA generates optimal fault

detection residual when only one set of variables are affected by a

fault.

18

Given the efficiency, PCA, PLS, and CCA-based moni-

toring methods have been intensively extended to solve various

monitoring problem. Other MVA-based monitoring methods

were also proposed and efficiency has been reported.

21−23

How-

ever, these methods generally assume that the measured vari-

ables are linearly related, which limits their applications in

nonlinear processes.

For nonlinear process monitoring, the neural networks (NN)-

based methods,

24,25

the kernel learning methods,

26−28

and the

just-in-time learning methods

29,30

are the basic ones. The

NN-based methods extract features through nonlinear mapping,

which is relatively sophisticated and generally requires a large

amount of computation. Moreover, the structure and parame-

ters should be determined in designing an NN for monitoring,

which remains a challenge. The kernel-based methods replace

the nonlinear mapping through kernel functions and then

extract features in the high-dimension space. Although efficiency

is shown, the selection of related parameters and kernel func-

tions is subjective, which significantly affects monitoring results.

Recently, just-in-time learning (JITL) approaches have been

developed for nonlinear process modeling and monitoring.

29−31

The basic idea of a JITL method is to establish several local

Received: April 26, 2018

Revised: August 7, 2018

Accepted: September 13, 2018

Published: September 13, 2018

Article

pubs.acs.org/IECR

Cite This: Ind. Eng. Chem. Res. 2018, 57, 13783−13792

© 2018 American Chemical Society 13783 DOI: 10.1021/acs.iecr.8b01796

Ind. Eng. Chem. Res. 2018, 57, 13783−13792

Downloaded via EAST CHINA UNIV SCIENCE & TECHLGY on December 30, 2018 at 07:25:16 (UTC).

See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles.