"电线-端子压接模具应用技术及质量要素"

版权申诉

174 浏览量

更新于2024-04-04

收藏 6.35MB PPT 举报

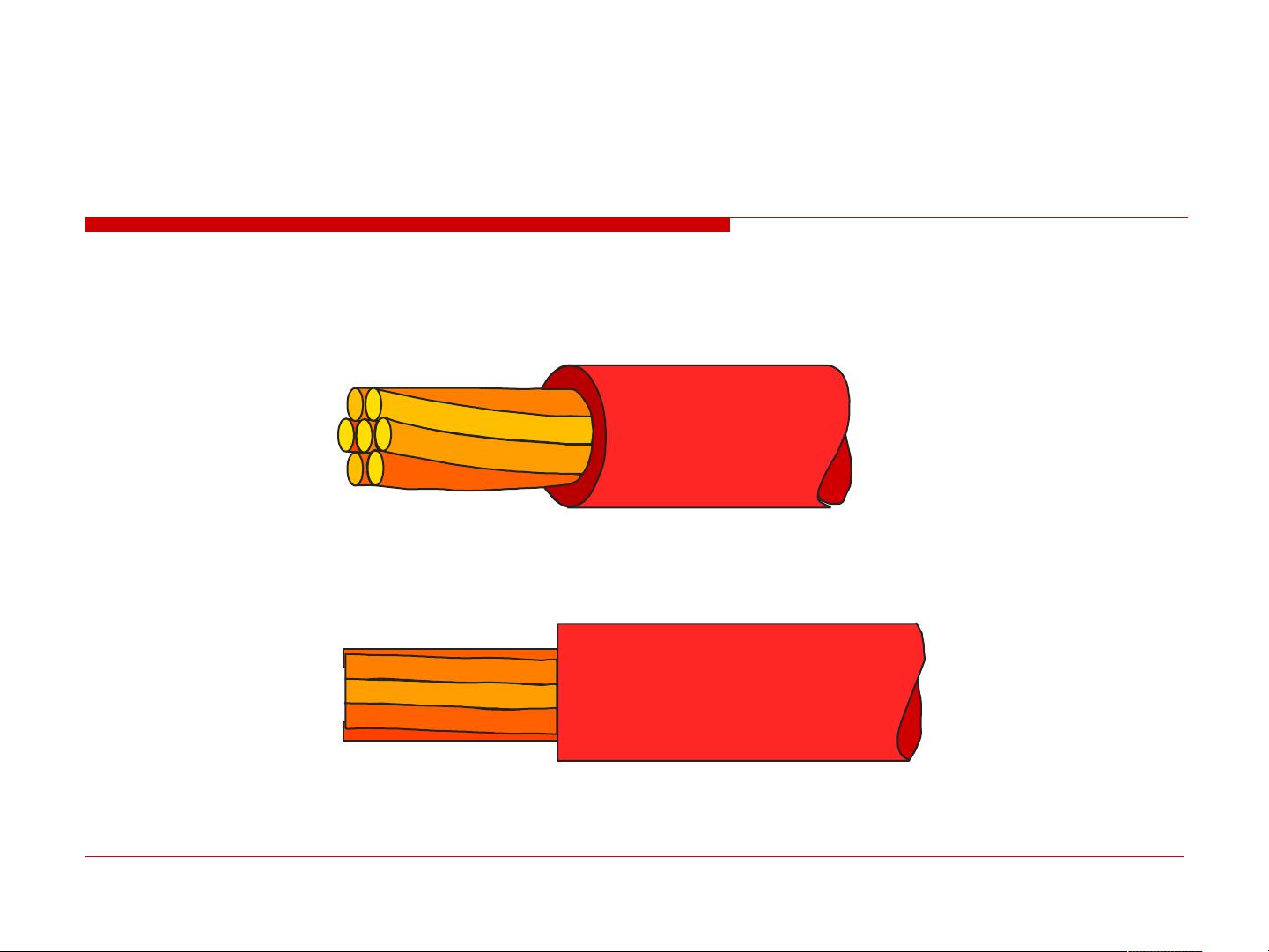

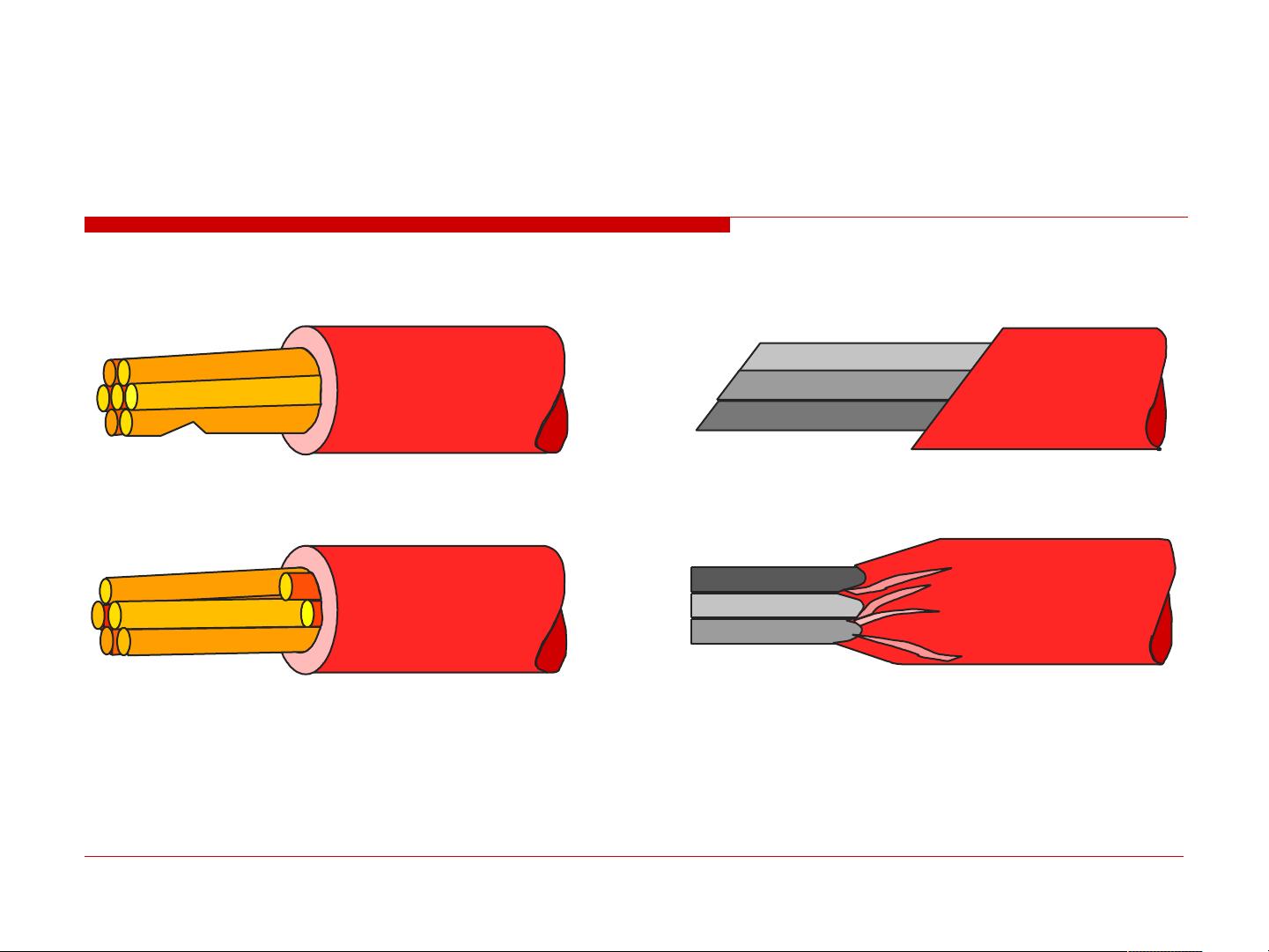

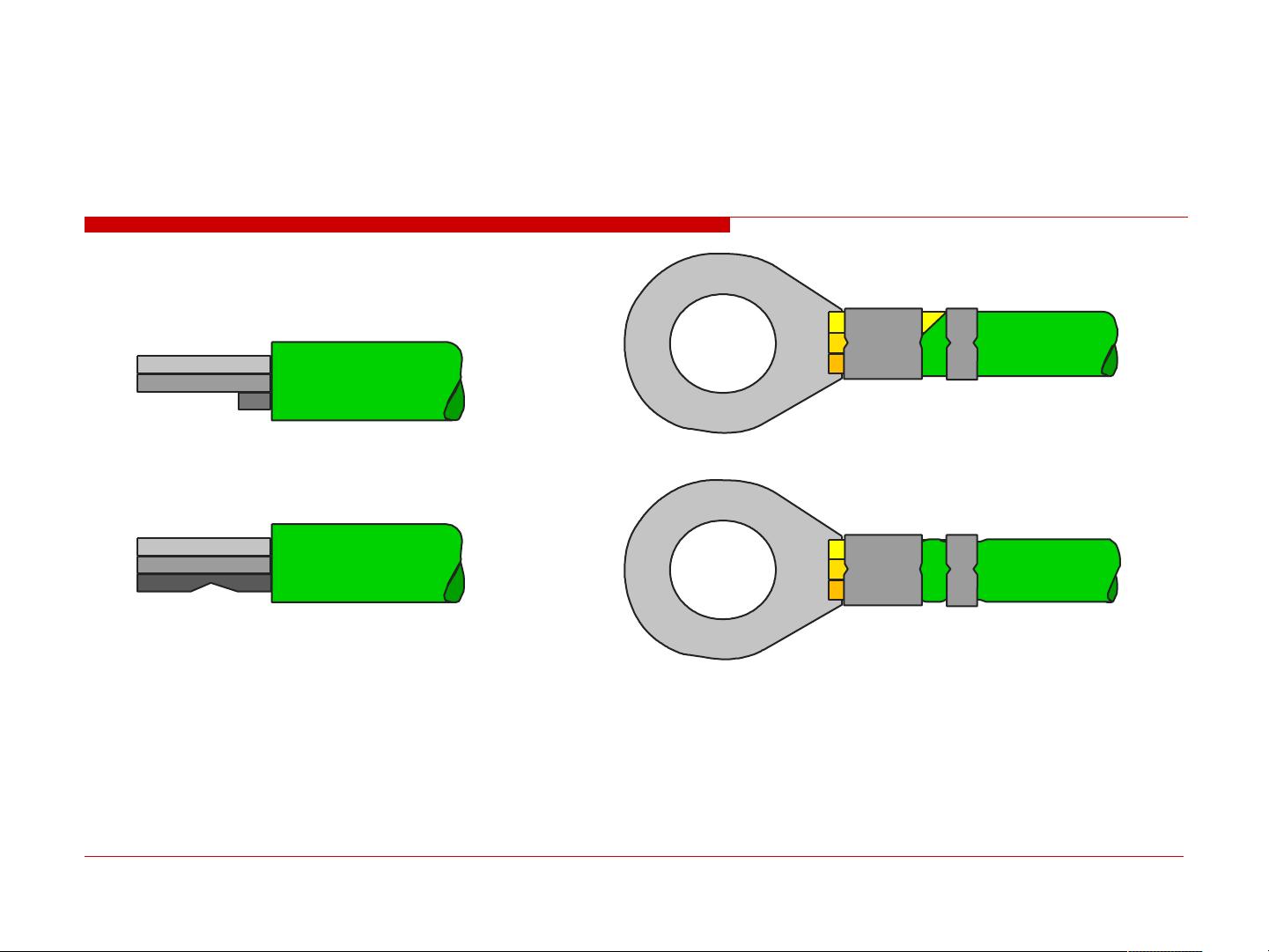

In the application of wire terminal crimping mold, the key components for achieving high quality terminations include wire, terminals, tooling, documentation, and quality trained personnel. The quality of a termination depends on the strands of wire, the gauge of wire, the level of twist (whether low or high), whether it is solid or stranded, the insulation, and the wire size. The Cross-Sectional Area (CMA) can be calculated using the formula CMA = d^2, where d is the diameter and N is the number of strands. It is essential to use the correct wire size for the terminal being used to ensure a quality termination. Proper training of personnel is also crucial in ensuring that terminations are done correctly the first time. By using high quality components and following proper procedures, a satisfied customer can be achieved.

2023-06-04 上传

2023-07-23 上传

2023-06-04 上传

2023-06-04 上传

2023-06-04 上传

2023-10-11 上传

2024-02-21 上传

2023-03-28 上传

南抖北快东卫

- 粉丝: 74

- 资源: 5588

最新资源

- 解决本地连接丢失无法上网的问题

- BIOS报警声音解析:故障原因与解决方法

- 广义均值移动跟踪算法在视频目标跟踪中的应用研究

- C++Builder快捷键大全:高效编程的秘密武器

- 网页制作入门:常用代码详解

- TX2440A开发板网络远程监控系统移植教程:易搭建与通用解决方案

- WebLogic10虚拟内存配置详解与优化技巧

- C#网络编程深度解析:Socket基础与应用

- 掌握Struts1:Java MVC轻量级框架详解

- 20个必备CSS代码段提升Web开发效率

- CSS样式大全:字体、文本、列表样式详解

- Proteus元件库大全:从基础到高级组件

- 74HC08芯片:高速CMOS四输入与门详细资料

- C#获取当前路径的多种方法详解

- 修复MySQL乱码问题:设置字符集为GB2312

- C语言的诞生与演进:从汇编到系统编程的革命