、

Microstructure and toughness

of

coarse grain heat-affected

zone

for

Nb-microalloyed

X80

pipeline steel

Microstructute and toughness of coarse grain hèat-affected

zone for Nb-microalloyed

X80

pipeline steel

、

Li

Y.

句

;uan

,

Li

Wushen

α

nd

Chen Renhua

李亚娟,李午申,陈仁华*

事

•

Absfract

Based on welding thermal simulation on Nb-microalloyed X80 pipeline steel using Gleeble-3500 thermal simulation

equ

ψ

阳风

microstructure

and

impact toughness in

coα

rse

grain

heat

吨庐

cted

zone ( CGHAZ) under

d

拼

rent

附

lding

parameters

were

investigated in this paper. The results show that high heat

inp

山

with

1

,

仰

preheats

or low

he

α

t

inputs with

high preheats should

be

α

pplied

to

α

chieve

high impact toughness. Coarse

original

αILMenite

grains

mα

:y

lower impact

toughness. CGHAZ microstructure

is

mostly composed

of

叩

'P

er

b

α

inite

,

. granular

b

α

inite

and lath bainite.

Th

e phase

composition

of

microstructure and the

qu

α

ntity

,

size " shape

of

M/

A constituents both

ha:

肥电

ffects

on impact toughness .

•

Key words Nb-microalloyed

X80

pipeline steel , heat-affected

zone

, microstructure , toughness

57

o

Introduction

The

transportation

of

oil

and

natural

gas

t'h

rough com-

plex

geographic

environment

demands

adequate

strength

and

toughness

for

the

pipeline

stee

l. Following

the

X65

and

X70

,

X80

pipeline

steel

is

applied

in

the

West-East

gas

pipeline.

X80

pipeline

steel

is

granular

bainite

stee

l.

Now

there

are

two different alloying

methods

for

X80

pipe-

line

steel

、,

Mo-alloyed with

TMCP

processing

and.

Nb-al-

loyed

with

HTP

processing[

1]

•

The

chemical

composition

of

Nb-microalloyed

X80

pipeline

steel

is

designed

with low

carbon

, high

manganese

and

chromium

containing.

The

content

of

niobium

is

improved

to 1

%.

Th

e

content

of

mo-

lybdenum

is

reduced

and

then

the

cost is contro

l1

ed.

The

increase

of

the

content

of

niobium

increases

recrystalliza-

tion

temperature

,

which

makes

it

possible

finish-rolling

at

higher

temperature

by

HTP

processing

than

by TMCP

pro-

C

Si

Mn

0.061

O.

199

1.

69

cessmg.

Microstructure

and

impact

toughness

in

coarse

grain

heat-affected

zone

(CGHAZ)

under

different

welding

pa-

rameters

have

been

investigated

through

thermal

simulation

experiments

on

Nb-microa

l1

oyed

X80

pipeline

steel

in

this

article.

1

Experimental

material

and

method

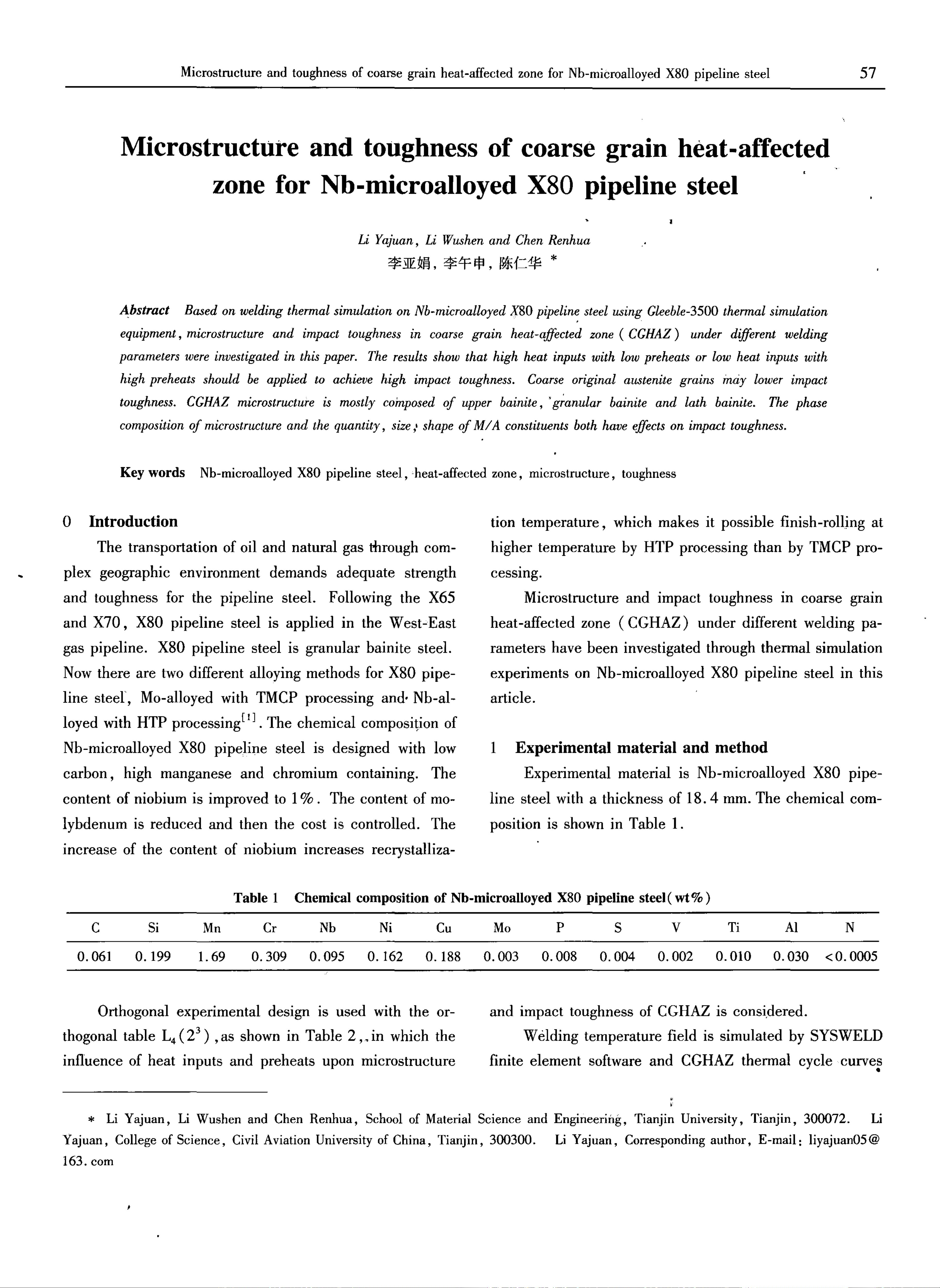

Experimental

material

is

Nb-microalloyed

X80

pipe-

line

steel

with a

thickness

of

18.

4 mm.

The

chemical

com-

position is shown

in

Table

1.

Table 1 Chemical composition

of

Nb-microa

Il

oyed X80 pipeline steel(

wt%)

Cr

Nb

Ni

Cu

Mo

P S V TI

AI

N

0.309 0.095

O.

162

O.

188

0.003 0.008

0.004 0.002 0.010 0.030

< 0.0005

Orthogonal

experimental

design

is

used

with

the

or-

thogonal

table

L4

(2

3

)

,

as

shown

in

Table

2

,咱

in

which

the

influence

of

heat

inputs

and

preheats

upon

microstructure

and

impact

toughness

of

CGHAZ

is

consi,

dered.

Welding

temperature

field is

simulated

by

SYSWELD

finite

element

software

and

CGHAZ

thermal

cycle

cump

b

*

Li

Yajuan ,

Li

Wushen

and

Chen

Renhua ,

School

of

Material Science and

Engineeri

吨,

Tianjin University , Tianjin , 300072.

Li

Yajuan ,

College

of

Science ,

Civil

Aviation

University

of

China , Tianjin , 300300.

Li

Yajuan , Corresponding author, E-mail: liyajuan05@

163.

com

,

'