724 CHINESE OPTICS LETTERS / Vol. 7, No. 8 / August 10, 2009

Research on the resolution of micro stereo lithography

Xiang Wang (

)

∗

, Jijun He (

ÛÛÛ

FFF

), Xiangtao Pei (

777

), Peng Shao (

+++

),

Jiaru Chu (

±±±

[[[

XXX

), and Wenhao Huang (

©©©

ÓÓÓ

)

Department of Precision Machinery and Precision Instrumentation, University of Science and Technology of China,

Hefei 230026, China

∗

E-mail: wxyf@ustc.edu.cn

Received November 4, 2008

Micro stereo lithography is a kind of technology utilizing the solidified effect that photo curable polymer

will appear under ultraviolet (UV) laser exposure. It is widely used in three-dimensional (3D) micro

fabrication. We get the experimental values of a pair of UV laser curing coefficients, absorption coefficient

and critical curing energy, of curable resin by fitting the calculation results of the Gaussian beam theory

and experimental curing results. The theoretical relation between the curing unit’s shape and the exposure

features of time and intensity of convergent Gaussian beam is presented. The calculation and experimental

results of curing unit under d ifferent conditions agree well with each other. This research offers a steady

base for further research about th e improvement of resolution.

OCIS codes: 220.3740, 220.4000, 220.4610.

doi: 10.3788/COL20090708.0724.

Micro stereo lithography (MSL) is a method derived from

the technology of rapid prototyping (RP) in the field

of laser-based micr o fabrication. The basic principle is

that, under an ultraviolet (UV) exposure, some kinds of

polymers can absorb photons and cause a photochemi-

cal reaction, leading to pho to p olymerization

[1]

. MSL is

attracting global concern for its three-dimensional (3D)

micro fabrication ability. Kobayashi et al. resear ched the

polymerization of freely movable 3D microstructure us-

ing conductive photo curable resin

[2]

. Zha ng et al. used

a solution consisting of curable resin and c e ramic sus-

pens ion to lead a layer-by-layer polymerization on silicon

substrate

[3]

. Products of micros tructure using the tech-

nology of UV p olymerization of liquid resin and lithog-

raphy with mask are being provided by Micro-TEC-D

company

[4]

. It is now one of the most importa nt research-

ing realms in 3D micro fabrication

[5,6]

.

MSL uses scanning UV beam to focus on the UV cur-

able resin, leads to the polymeriz ation, and then form-

ing points, lines, planes, and finally the layer-by-layer

3D microstructure. In this letter, we analyze the reso-

lution of MSL through researching the relation between

the characteristics of single curing unit and fo c al spot by

the principle of micro photo polymerization. A mathe-

matical model is constructed based on the exp erimental

data. This will offer a steady base for the future 3D mi-

cro fabrication study.

According to the photon absorption theory, after ex-

posure, the molecules will turn into excited sta te and

energy will be tra ns mitted or reflected in co mpound sys-

tem. With the interaction of chromophore (chemical

bonds or groups that can absorb photons), polymeriza-

tion and cross linking reaction will happen, resulting in

phase transformation and photo curing

[7]

. Photo cur ing

is a kind o f photochemical reaction resulting from the ab-

sorption of photon by photo-curable compound. When

the absorption happ e ns, if the absorbed photons’ energy

lets the molecules reach the critical value of excitation,

the liquid resin’s photo curing can appear. Generally,

the main properties to evaluate the liquid photo curable

resin include physical properties, optical properties in a

sp e cific wavelength, and mechanical prop e rties. Analy-

sis of influences on photo polymerization is mainly about

its optical performance parameter. Photo sensitive resin

used in MSL research is mainly UV curable resin. And

the principal coefficients reflecting the curing property

contains critical curing energy and absorption coefficient.

The feature value of a particular kind of resin is different

when the wavelength of UV exposure is different, so only

through the curing experiments and theoretical calcula-

tion can the feature para meters be fixed.

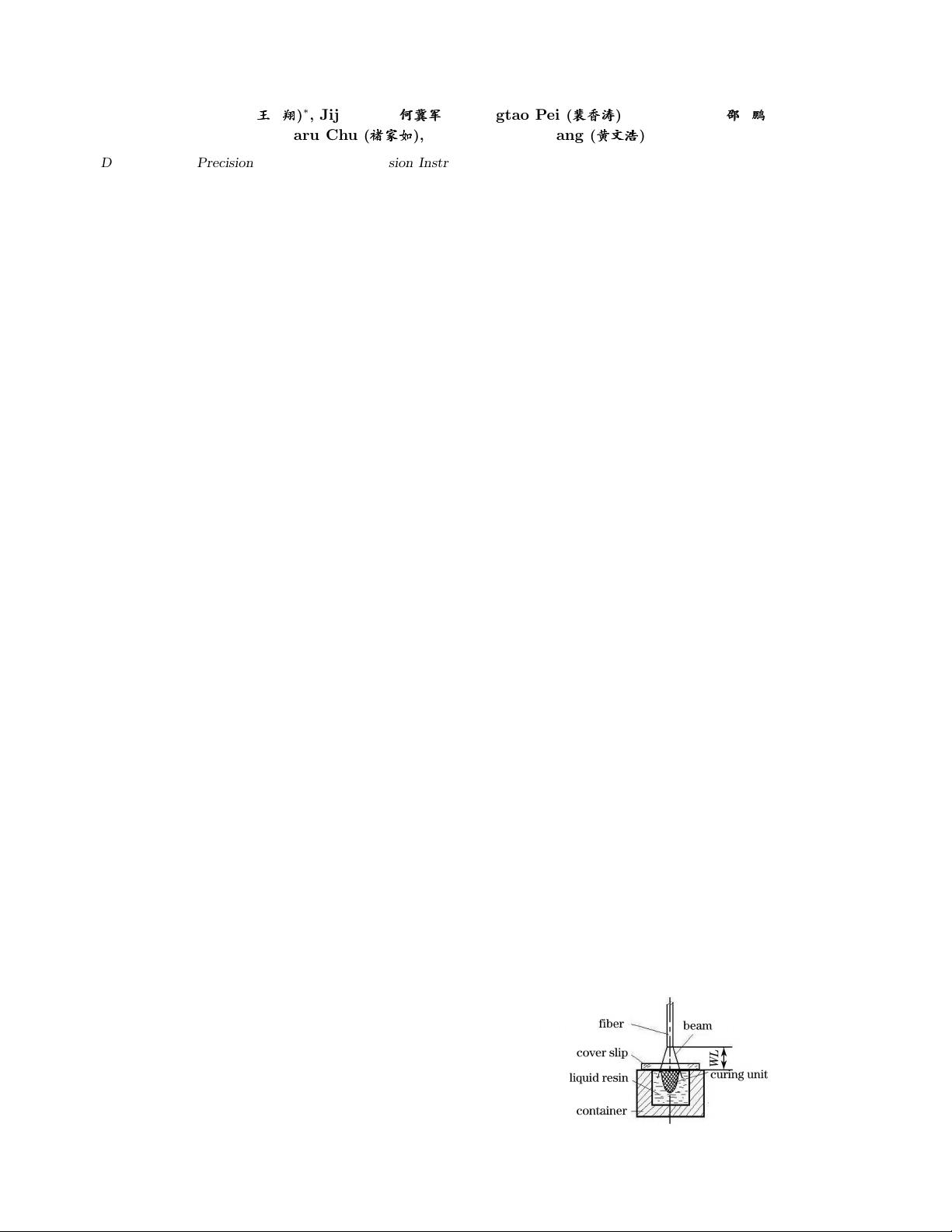

The experimental system is schematically shown in

Fig. 1. The process of exper iment is as follows. The UV

laser exits from quartz fiber, passes through the cover

slip, reaches the container full of liquid resin, and reacts

with resin, while single point curing unit is produced. In

the experiment, the fiber has a numerical aperture (NA)

of 0.37 and a radius of 0.6 mm. Its working distance

(from the tip face of the fiber to the liquid level of resin

including the depth of cover slip) WL = 0.38 mm and

the exposure spot radius on liquid level is 0.9 mm. The

intensity of exposure spot can be measured by UV in-

tensity meter (UV-A type Developed by Beijing Normal

University, whose measurable peak value of wavelength

is 365 nm, minimum resolution is 0.1 µW/cm

2

, a nd accu-

racy is ±5%). Usually, the photo poly merization of UV

curable resin obeys the Beer-Lambert law of absorption

which can be expressed as

[8,9]

I = I

0

exp(−αz), (1)

Fig. 1. Principle of experimental system.

1671-7694/2009/080724-04

c

2009 Chinese Optics Letters