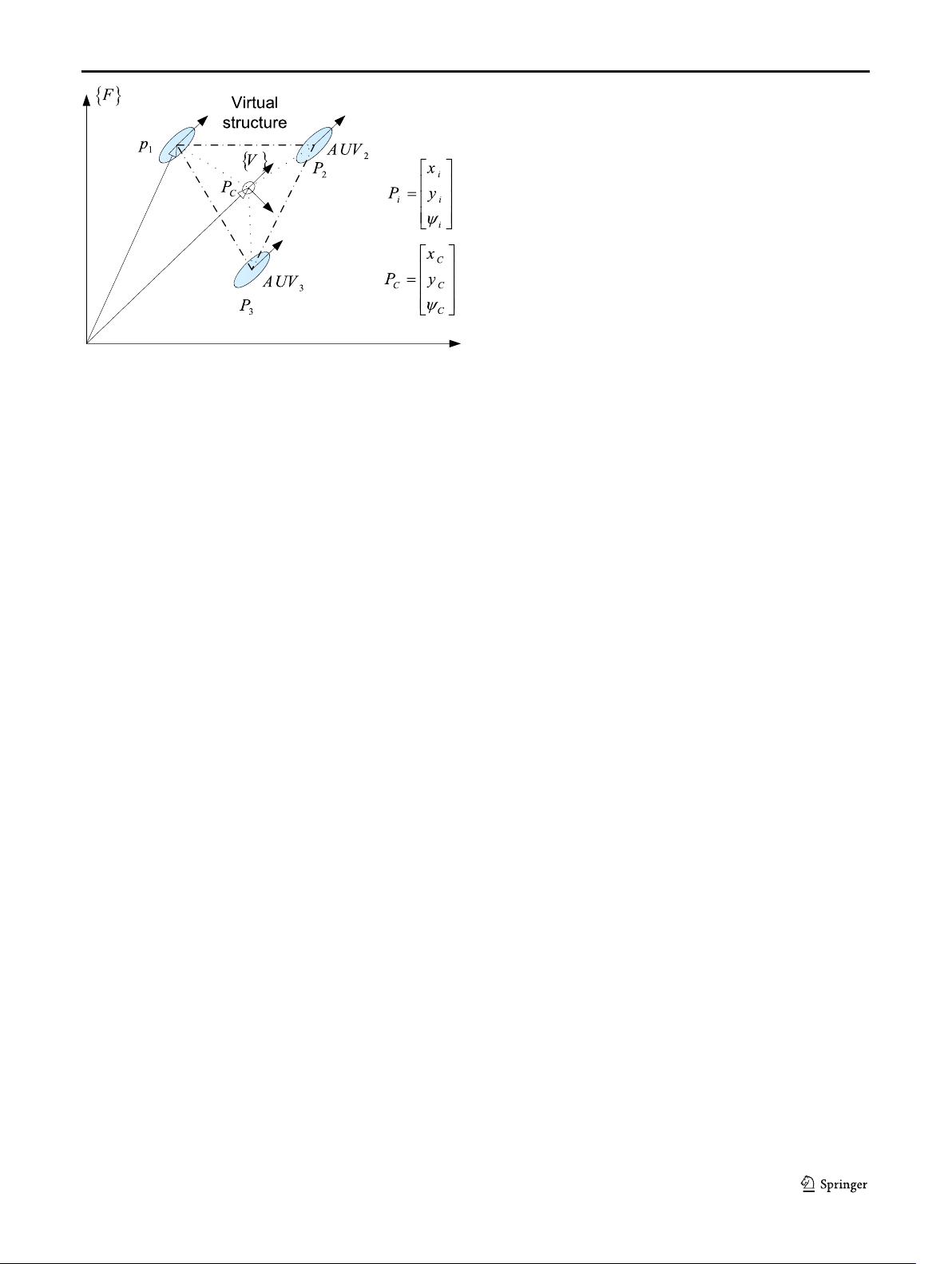

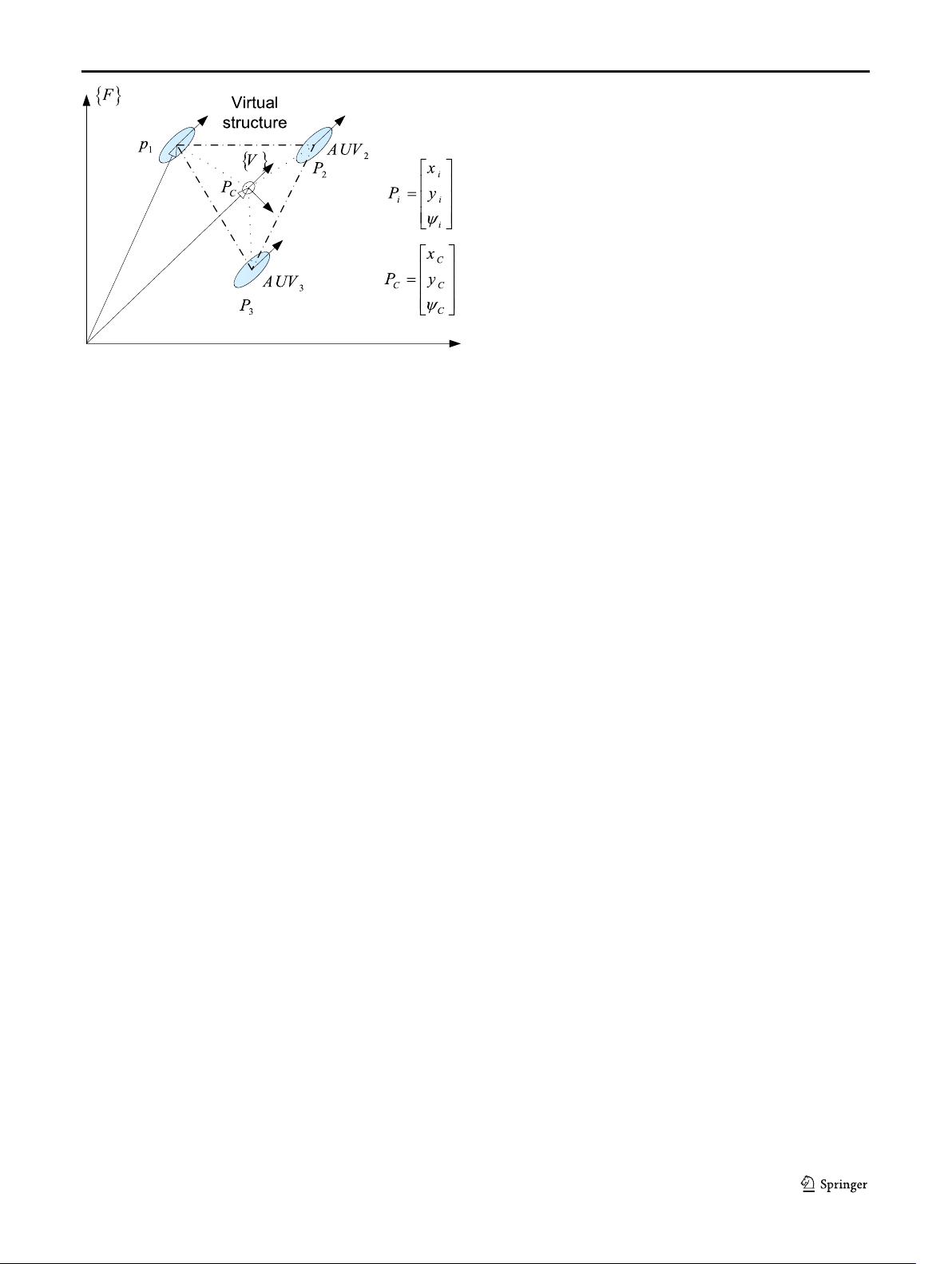

considered equal to the number of AUVs and one-

to-one correspond ence is established between

them. The desired formation is obtained by mini-

mizing the position error function, which is defined

based on the current position of the AUVs and their

desired position in the virtual structure.

Stepe 2: Converting the virtual structure’s desired motion

into desired commands for each of the AUVs in

the group: Having adjusted the desired virtual

structure, a virtual force is applied to the virtual

structure so that the structure can be moved to the

next point. In this section, the vehicle’smotionca-

pacity is taken into consideration.

Stepe 3: Designing an individual tracking controller for each

of the AUVs: After transferring the virtual structure

to the new position (done in Step 2), the control

inputs for each vehicle are designed in such a way

that the vehicle moves to its new corresponding

point in the virtual structure. A simple way for the

movement of vehicles to the desired position is

changing direction towards the desired position

and then transferring to the target point.

Virtual structure is usually used for formation control in

mobile robots, spacecraft [42–44] or small satellites [11,

45–47]. The employment of virtual structure approac h in

spacecraft formation control was presented in [48], where for-

mation feedback from the spacecraft to the virtual structure

was consulted. This would give robustness to the structure of

formation against internal or external disturbances and lead to

better performance. The control strategies of the distributed

virtual structure along with the corresponding coupling of

single-wheeled mobile robots are introduced in [49]. The cor-

responding coupling would create a trade-off between ensur-

ing the tracking of each robot’s desired trajectories and main-

taining the shape of the formation when faced with

disturbances, which can result in higher robustness of the pro-

posed formation structure. The exponential stability of the

dynamics of formation error is proven and the proposed con-

trol design is practically applied. In [50], the two-layer distrib-

uted formation learning control was presented for one group

of AUVs, which included an adaptive distributed observer in

the upper layer and a decentralized deterministic learning con-

troller in the lower layer. The upper layer estimates the virtual

leader’s states and dynamics. The formation tracking control

and learning performance of the neural network with local

information are done in the lower layer.

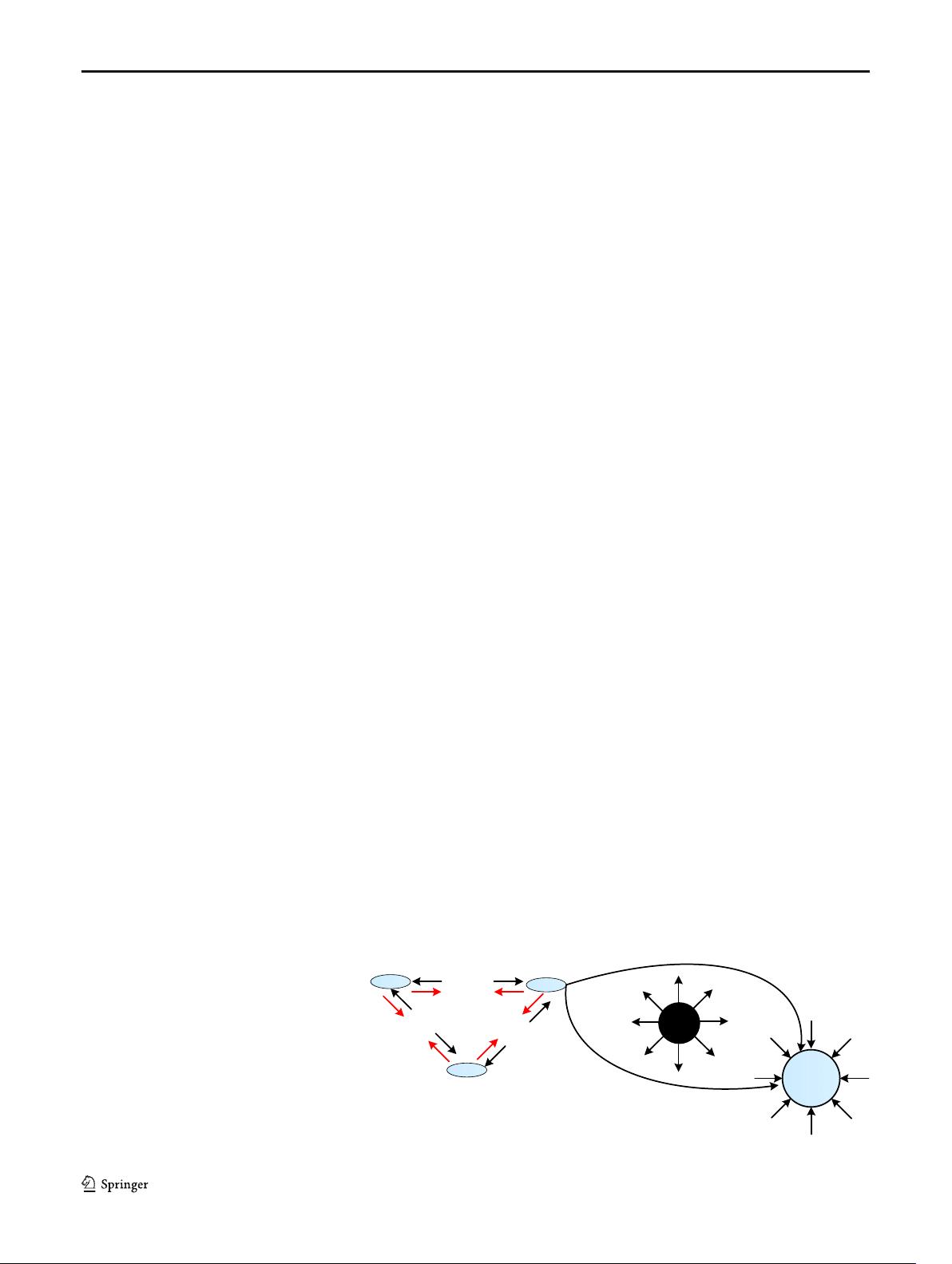

3.3 Formation Control Based on Behavioral Structure

Behavior-based formation control was first introduced by

Balch and Arkin in formation control [51]. This method uses

a weighted hybrid of different mission objectives in order to

generate vehicle control inputs. Generally, control targets in-

clude maintaining desired formation, moving towards the tar-

get, avoiding obstacle collisions, and avoiding inter-group

collisions. Each of the aforementioned items is prioritized

with different gains and the obtained average is given to each

vehicle as a control input. Meeting several control objectives

simultaneously is one of the benefits of this approach. It is,

however, hard to describe the dynamic of the group and guar-

antee the stability of the whole system, because the kinematic

and dynamic features of the vehicle are not taken into consid-

eration. The behavioral structure method is commonly applied

in combination with the artificial potential field method. In

[52], the formation control of a swarm of robots is considered

on the basis of the behavioral method for the generation of

formation and obstacles avoidance. To create an initial forma-

tion, the classification-based target searching algorithm is

used so that any arbitrary shape can be generated. Moreover,

the behavior-based approach is employed for moving in an

unknown obstacle-strewn environment. Based on the non-

linear dynamic systems theory, the distributed formation con-

trol and obstacle avoidance are presented in [53]. The desired

trajectories are gained based on the behavioral variables’ state

space. A combination of behavior-based formation approach

and artificial potential field is one of the most common

methods of formation control, which is also used for control-

ling a group of AUVs with simplified second-order dynamic

equation. The potential function for each vehicle is defined in

terms of goals, obstacles and formation structures and the

control law is designed based on Lyapunov’sdirectmethod.

This will ensure that the AUVs will effectively follow the goal

and avoid obstacles [54]. The combination of virtual and be-

havioral structures is the focal point of other studies conducted

on combining different methods of formation control. This

approach is used for the formation control of a group of mo-

bile robots. Each robot is modeled by an electric charge. Upon

defining the attraction forces, the robots would move towards

Fig. 4 The virtual structure including three vehicles

J Intell Robot Syst (2021) 101:

Page 5 of 26 67