"注塑机控制系统中PLC的应用及改造研究"

51 浏览量

更新于2024-03-24

收藏 2.63MB DOC 举报

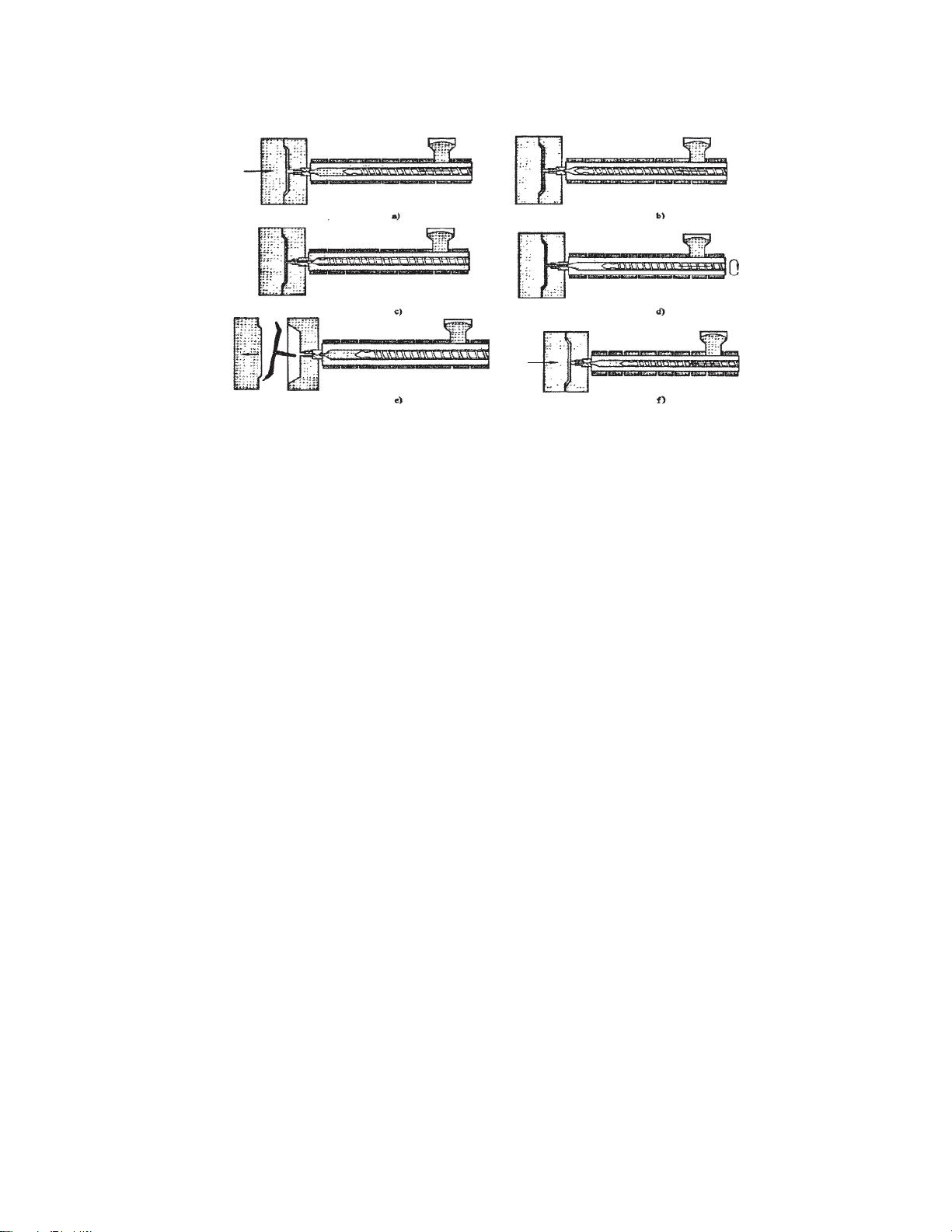

Injection molding is a complex process that requires precise control in order to produce high-quality plastic products. The control system of the injection molding machine plays a crucial role in determining the quality of the final product. Traditional control methods, such as using relays and contact switches, have limitations in terms of maintenance, reliability, and accuracy. With the advancement of electronic technology, it has become necessary to upgrade the control system of injection molding machines.

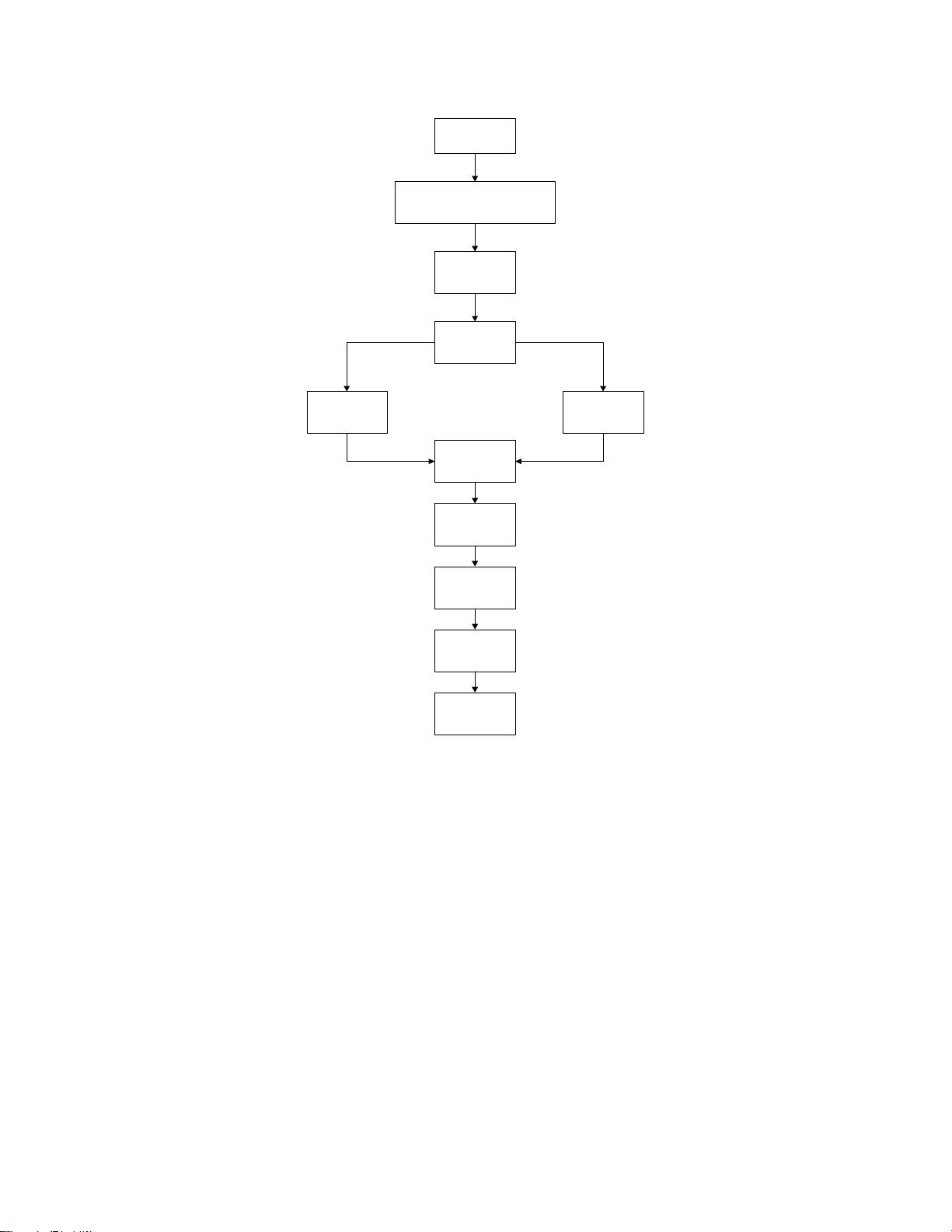

This undergraduate thesis explores the application of PLC (Programmable Logic Controller) in the control system of injection molding machines. The research aims to improve the overall efficiency, precision, and reliability of the injection molding process. The study analyzes the structure of injection molding machines and introduces the programming and usage methods of the Siemens S7-200 PLC. By utilizing configuration software for simulation, a complete injection molding machine system controlled by PLC is designed.

The benefits of using PLC in the control system of injection molding machines are numerous. PLCs offer higher reliability, faster response times, and greater precision compared to traditional control methods. The system designed in this research project aims to achieve low energy consumption, reduced noise levels, easy control of clamping force, smooth operation, safety, reliability, and ease of maintenance.

In conclusion, the application of PLC in the control system of injection molding machines represents a significant advancement in the field of plastic manufacturing. By upgrading to PLC-based control systems, manufacturers can improve the quality, efficiency, and reliability of their production processes. This research contributes to the continued development and optimization of injection molding technologies, ensuring the production of high-quality plastic products for various industries.

2023-05-02 上传

2024-01-04 上传

2023-05-25 上传

2023-12-29 上传

2023-03-30 上传

2023-06-03 上传

zzzzl333

- 粉丝: 746

- 资源: 7万+

最新资源

- AirKiss技术详解:无线传递信息与智能家居连接

- Hibernate主键生成策略详解

- 操作系统实验:位示图法管理磁盘空闲空间

- JSON详解:数据交换的主流格式

- Win7安装Ubuntu双系统详细指南

- FPGA内部结构与工作原理探索

- 信用评分模型解析:WOE、IV与ROC

- 使用LVS+Keepalived构建高可用负载均衡集群

- 微信小程序驱动餐饮与服装业创新转型:便捷管理与低成本优势

- 机器学习入门指南:从基础到进阶

- 解决Win7 IIS配置错误500.22与0x80070032

- SQL-DFS:优化HDFS小文件存储的解决方案

- Hadoop、Hbase、Spark环境部署与主机配置详解

- Kisso:加密会话Cookie实现的单点登录SSO

- OpenCV读取与拼接多幅图像教程

- QT实战:轻松生成与解析JSON数据