SiC粉末对AISID2模具钢电火花加工及疲劳寿命影响研究

78 浏览量

更新于2024-06-18

收藏 3.24MB PDF 举报

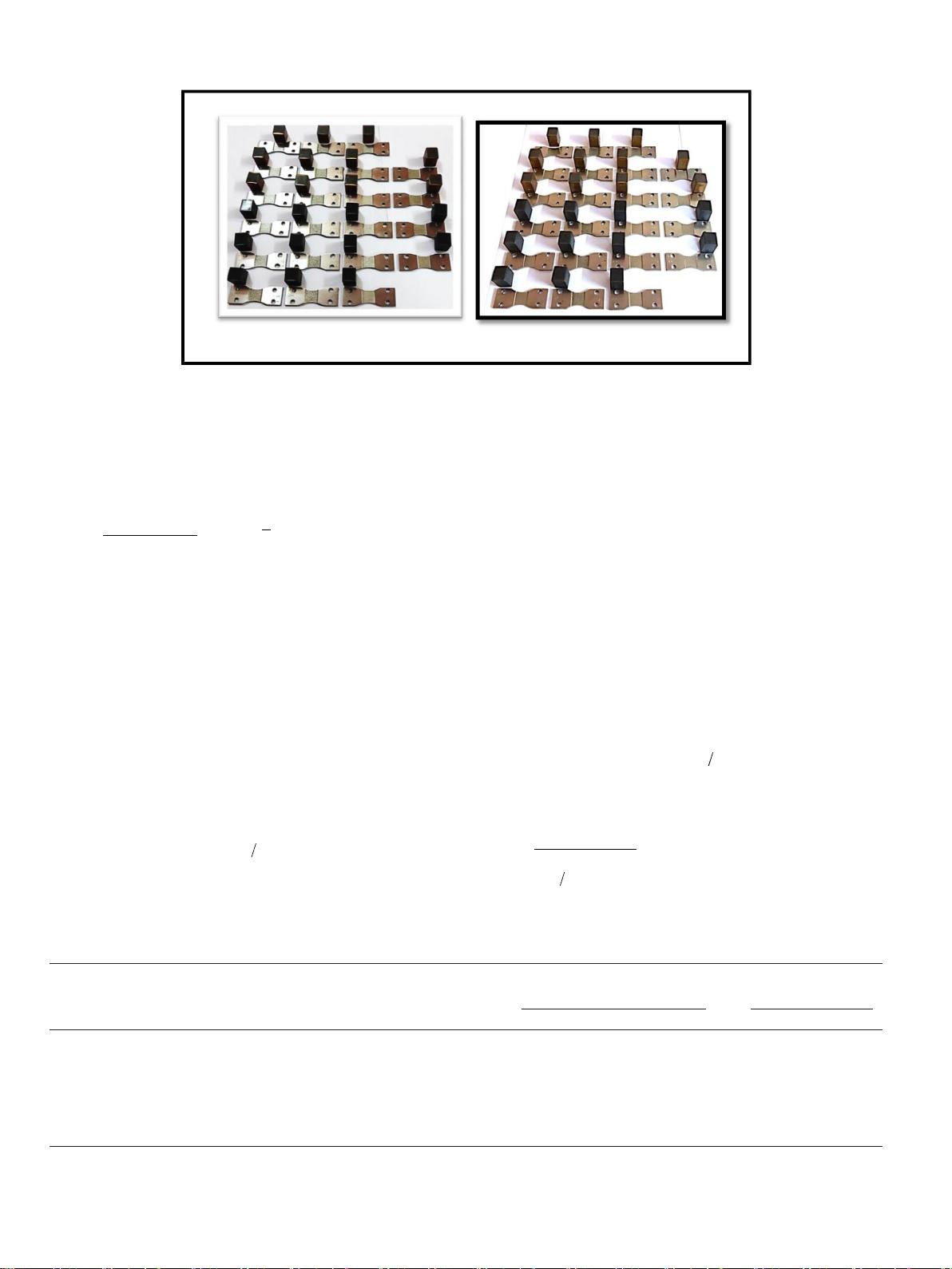

"这篇研究论文探讨了SiC混粉电火花加工(PMEDM)对AISI D2模具钢表面白层厚度、热流密度以及疲劳寿命的影响。通过使用铜电极和石墨电极,配合不同SiC粉末浓度,分析了工艺参数的变化对加工效果的显著影响。研究发现,添加SiC粉末可以显著降低白层厚度,增加总热流密度,并对疲劳寿命产生积极影响。"

文章详细内容:

在电火花加工(EDM)领域,SiC混粉加工是一种提升工艺效率和表面质量的方法。通过在电介质中混合SiC微粉,可以增强放电稳定性,从而提高材料去除率和表面粗糙度。在本研究中,作者对比了单独使用煤油作为电介质与使用SiC混粉的加工效果,特别是在AISI D2模具钢上。

实验设计采用了响应面法(RSM),分两组进行,一组是常规煤油电火花加工,另一组是PMEDM。通过ANSYS 15.0软件进行有限元分析(FEM),模拟并计算了电火花加工过程中的总热流密度和工件的疲劳寿命。结果显示,石墨电极产生的总热通量较铜电极高出82.4%,而当使用SiC粉末与石墨电极时,总热通量进一步提高至91.5%。

白层厚度(WLT)是衡量电火花加工表面质量的重要指标。研究发现,无论是在大电流还是小电流条件下,使用铜电极和SiC粉末都能显著减少WLT,最低达到5.0μm和5.57μm,相较于仅使用煤油和相同电极,WLT分别减少了134%和110%。这表明,SiC粉末有助于改善加工表面的完整性。

此外,疲劳寿命也是评价模具钢性能的关键因素。在实验中,铜电极在PMEDM下的疲劳安全系数相对于仅使用煤油和铜电极的情况提升了7.30%,而与石墨电极相比,这一提升更是达到了14.61%。SiC粉末的加入使得疲劳寿命得到显著提高,这可能归因于白层厚度的减小和表面质量的改善。

SiC混粉电火花加工对AISI D2模具钢的表面处理有显著的优化效果,它能减少有害的白层厚度,提高总热流密度,进而改善工件的疲劳寿命。这对于模具制造行业,尤其是对于高要求的模具钢应用,具有重要的实践意义。通过优化工艺参数,结合SiC粉末的使用,可以实现更高效、高质量的电火花加工。

2020-07-11 上传

2022-07-14 上传

2021-09-25 上传

2023-06-13 上传

2023-04-27 上传

2023-05-05 上传

2024-05-23 上传

2024-04-11 上传

2023-07-25 上传

cpongm

- 粉丝: 5

- 资源: 2万+

最新资源

- AirKiss技术详解:无线传递信息与智能家居连接

- Hibernate主键生成策略详解

- 操作系统实验:位示图法管理磁盘空闲空间

- JSON详解:数据交换的主流格式

- Win7安装Ubuntu双系统详细指南

- FPGA内部结构与工作原理探索

- 信用评分模型解析:WOE、IV与ROC

- 使用LVS+Keepalived构建高可用负载均衡集群

- 微信小程序驱动餐饮与服装业创新转型:便捷管理与低成本优势

- 机器学习入门指南:从基础到进阶

- 解决Win7 IIS配置错误500.22与0x80070032

- SQL-DFS:优化HDFS小文件存储的解决方案

- Hadoop、Hbase、Spark环境部署与主机配置详解

- Kisso:加密会话Cookie实现的单点登录SSO

- OpenCV读取与拼接多幅图像教程

- QT实战:轻松生成与解析JSON数据