2 Design of embedded robust control systems using MATLAB

®

/Simulink

®

fast control algorithm and to create interface schemes with minimum possible delay

of signal transmission. On the second place, the embedded control system should

possess stability in respect to external data. If, for instance, the data, necessary to

obtain the result, do not arrive in time, then the system cannot produce the required

result in time. In such a case, the system should not lock, but has to continue to give

appropriate result in real time.

The process of developing embedded control systems has strongly multidisci-

plinary character, since it is required to perform a system integration of problems,

associated with

– derivation of mathematical models of physical plants, sensors, communication

hardware, and so on,

– development of methods for high performance control,

– embedding of control algorithms in different hardware and software platforms,

– carrying out communication with remote plants,

– solving problems associated with power supply.

The theoretical foundation of the embedded control systems is the theory of

hybrid systems. The hybrid systems combine continuous processes described by dif-

ferential or difference equations and discrete-event processes, described by finite

automata. Such systems arise in a natural way in the control of continuous processes

by the aid of digital devices and their investigation require a synthesis of control

theory and computer science. The usage of complicated robust and adaptive control

laws leads to the necessity of developing embedded system which work under the

conditions of restricted processor accuracy and relatively small sampling interval.

This represents a serious challenge both from theoretical and practical point of

view.

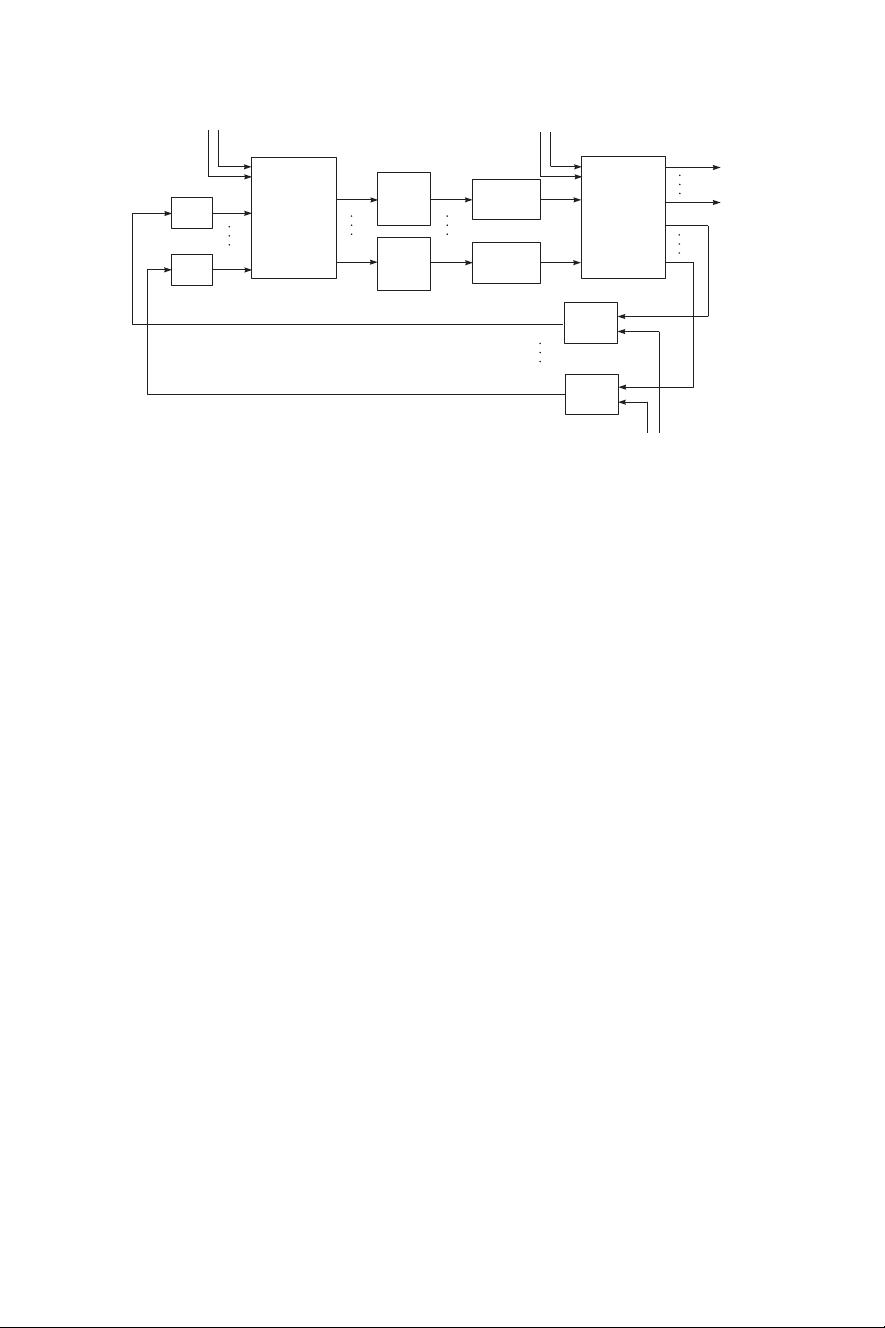

1.2 Structure and elements of embedded control systems

1.2.1 Typical block diagram

From control theory point of view, the embedded control system for a continuous-

time plant represents a closed-loop multivariable digital control system with a block

diagram, shown in Figure 1.1. Very few plants encountered in practice are inherently

digital, so we assume that generally the plant is continuous-time. Such systems are

called sampled-data systems.

The aim of the control system is to ensure desired behavior of controlled plant

outputs in accordance with the reference signals in presence of unknown distur-

bances and noises in the closed loop. In the general case, the plant has m analog

control inputs produced by actuators and r analog outputs measured by the respective

sensors. The measurements are corrupted by noises which, along with the plant distur-

bances, may significantly affect the closed-loop system behavior. The analog sensor